Lightweight Composite Materials in Architecture: The "Power of Lightness" at the Osaka Expo

The 2025 Osaka Expo, themed "Building a Future Society for Our Lives," will prominently feature the "Blue Ocean Dome" designed by Shigeru Ban. This triple-dome structure combines a sense of "lightness" with unconventional recycled materials, promoting an architectural philosophy that embodies both humanistic care and environmental attributes. Among them, the second dome in the series — Dome B, boldly challenges the use of carbon fiber reinforced composites (CFRP) in its construction.

The positioning of this World Expo isThe "Living Lab" is located on Yumeshima Island, an artificial landfill island in Japan. The Expo aims to showcase and integrate cutting-edge global technologies and ideas to address various global issues. However, this man-made island has a significant structural limitation: its soil bearing capacity is relatively weak, which means that excavation depths cannot exceed 2.5 meters. This complicates the use of deep pile foundations, making them even impossible to implement.

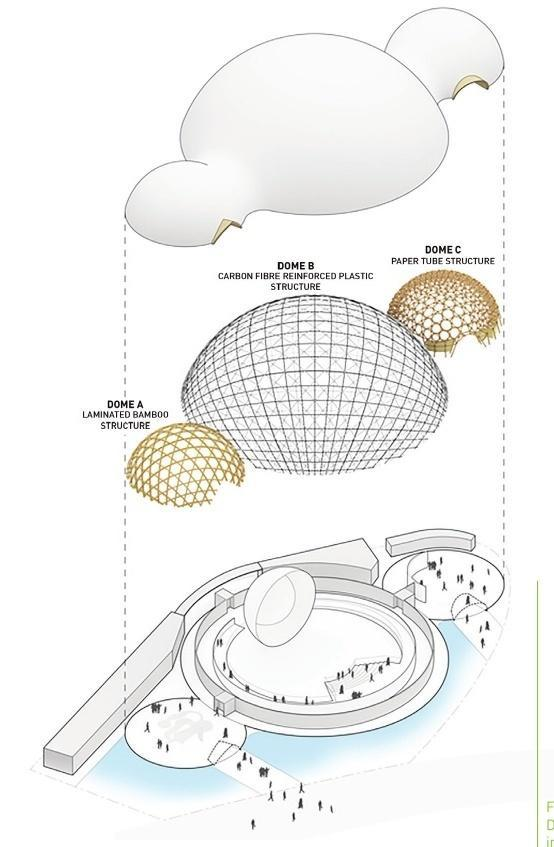

The "Blue Sea Dome" project is both a clear and powerful response to the structural constraints of the site and a full reflection of the Expo's theme. The building is designed with extreme lightness at its core, eliminating the need for deep pile foundations. By using cutting-edge materials such as carbon fiber composites, the weight of the building is significantly reduced. Therefore, this pavilion not only fulfills the 2025 Expo's commitment to sustainable development but also serves as a technical demonstration in a practical and feasible manner. The project transforms engineering constraints into opportunities for innovation, embodying the vision of a "living laboratory" — developing and testing new building technologies in real-world scenarios in real time (see Figure 1).

Blue Ocean Dome: A Vision for Marine Conservation

The "Blue Ocean Dome" pavilion (see Figure 2) was spearheaded by the Japanese nonprofit organization "Zero Emissions Research and Initiatives" (ZERI) in collaboration with Saraya Co, Ltd. The project aims to "revitalize the ocean's vitality" and enhance public awareness of the challenges facing the marine environment. It is an architectural response to the "Osaka Blue Ocean Vision"—a commitment proposed during the 2019 Group of Twenty (G20) Summit, dedicated to reducing marine plastic pollution.

2

The exhibition design by Shigeru Ban reflects.The goal of ZERI. He chose materials such as bamboo, recycled paper, and carbon fiber reinforced composites (CFRP), all of which possess sustainable attributes and align with the concept of recycling, fully demonstrating the ideals of a circular economy. One of the core elements of this vision is the reuse of the pavilion itself.

After the Expo closes, the pavilion will be dismantled and relocated to the Maldives to be used as a building structure for the local marine integrated development project."Second life" directly influenced design and engineering processes, such as ensuring through thermal simulation that the carbon fiber reinforced composite dome could withstand the high temperature and high humidity conditions of the Maldives. Ultimately, the architectural structure itself became a symbol of the NGO's philosophy, proving that innovation and circular concepts can create a lasting architectural legacy that transcends the six-month Expo cycle.

Based on circular design

The "Blue Ocean Dome" exhibition hall is an architectural complex composed of three interconnected domes (see Figure 3), each constructed using unique structural materials: bamboo, carbon fiber reinforced polymer (CFRP), and recycled paper. The design follows the principles of modular construction, low environmental impact, and maximizing reusability. Through this design, it breaks the usual "fate" of exhibition venues—where most venues are dismantled after the event, generating a large amount of waste. In contrast, this project sets a new benchmark for large temporary buildings by pre-setting a "lifecycle endpoint" for the architecture (i.e., a usable and sustainable subsequent purpose). Additionally, designing the exhibition hall to be movable to the Maldives provides a tangible example of the application of the circular economy in the construction industry.

Located at the entrance of the exhibition hallA dome with a span of 20 meters is constructed from multi-layer laminated bamboo. The central B dome, with a span of 40 meters, is the most innovative part of the project — it is the first large-scale architectural structure to use carbon fiber reinforced composite material tubes as the main load-bearing framework, and it is also the first building in Japan to use carbon fiber reinforced composite materials for seismic-resistant structures.

As an export and information consulting pointThe dome is constructed using 100% recycled paper tubes, which are also a signature design material of Shigeru Ban.

B Dome: Cutting-edge structure using carbon fiber reinforced composites

For the "Blue Sea Dome," carbon fiber reinforced composites (CFRP) offer advantages in both structure and logistics. The tensile strength of this material is five times that of steel, the stiffness is twice that of steel, while the weight is only a fraction of that of steel.

This extreme lightweight characteristic addresses the core challenge faced by the site on Dream Island.The total weight of the dome is even less than the weight of the soil excavated for the construction of its foundation. This lightweight engineering design eliminates the need for concrete piles on this reclaimed land. The omission of complex foundation engineering brings dual benefits: on one hand, it reduces material and labor costs, and on the other, it significantly shortens the construction period. This means that weight is no longer just a physical attribute, but becomes a strategic design parameter impacting engineering technology, economics, and construction timelines.

However, the use of innovative materials such as carbon fiber reinforced composites also presents challenges. This material is quite sensitive to temperature changes, necessitating precise engineering design, especially considering its subsequent relocation to the high-temperature and high-humidity environment of the Maldives. To ensure its load-bearing capacity and toughness, the team conducted thermal simulation analysis. This process indicates that modern engineering design cannot be limited to static load calculations; environmental factors must also be regarded as key parameters.

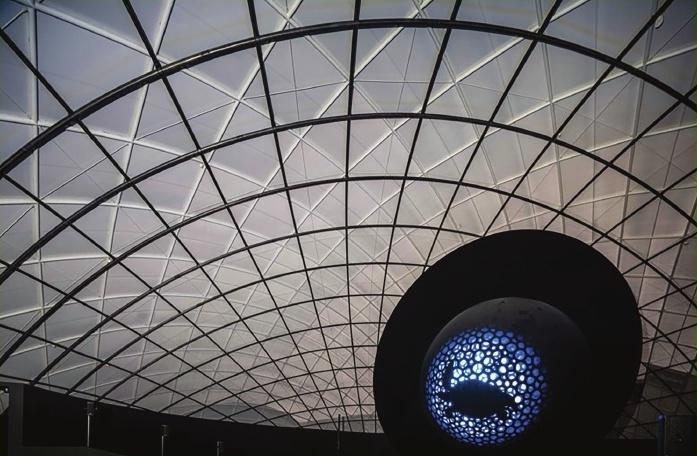

The structure of the dome also demonstrates the concept of multi-material engineering design. Although the main tubing is made of carbon fiber reinforced composites, the framework of the outer support membrane structure uses steel, while the inner layer uses carbon fiber reinforced composite tubing. This hybrid design indicates that composite materials are not intended to replace traditional materials but can complement them to build a structure system with superior performance. By optimizing the unique properties of each material component, higher structural efficiency and resilience can be achieved (see Figure 4).

From Concept to Daily Application: Making Innovation More Accessible

Designed by Shigeru BanThe "Blue Sea Dome" pavilion is a milestone in the field of contemporary architecture. By demonstrating the technical feasibility of composite materials and their environmental relevance, it has promoted the broader application of composite materials in the construction industry. The success of the carbon fiber reinforced composite dome is expected to encourage architects and engineers to apply such materials in more conventional scenarios, such as bridges, large-span buildings, or construction projects in complex geological conditions.

The ability of carbon fiber reinforced composites to significantly reduce structural weight opens up new opportunities for architectural design and construction.Especially in the fields of prefabrication and modular construction, which are key trends shaping the future of the architectural industry.

Ultimately, the project demonstrates that lightweight construction is not just an aesthetic issue, but a comprehensive solution that encompasses site selection, foundational engineering, transportation logistics, and construction schedule planning."Blue Sea Dome," as a public demonstration project, has validated the potential of these materials, reduced the perceived risk of adopting these materials in future projects, and paved the way for the construction industry to transition from elite experimentation to industrial standardization.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory