Luxury Brand's "Cap Black Technology": KraussMaffei Makes High-End Packaging More Stylish!

In the high-end cosmetics industry, every detail embodies quality. The crystal-clear, smoothly opening and closing cap of a perfume bottle is not only a guardian of functionality but also a silent expression of the brand's character and sustainable philosophy.

Novassu, a professional manufacturer from France, is one of the maestros behind the scenes transforming the stringent visions of these top brands into reality. From Chanel and Givenchy to Estée Lauder, Novassu, with the support of KraussMaffei technology, provides high-end cap and packaging solutions for these brands, jointly leading the forefront of packaging innovation.

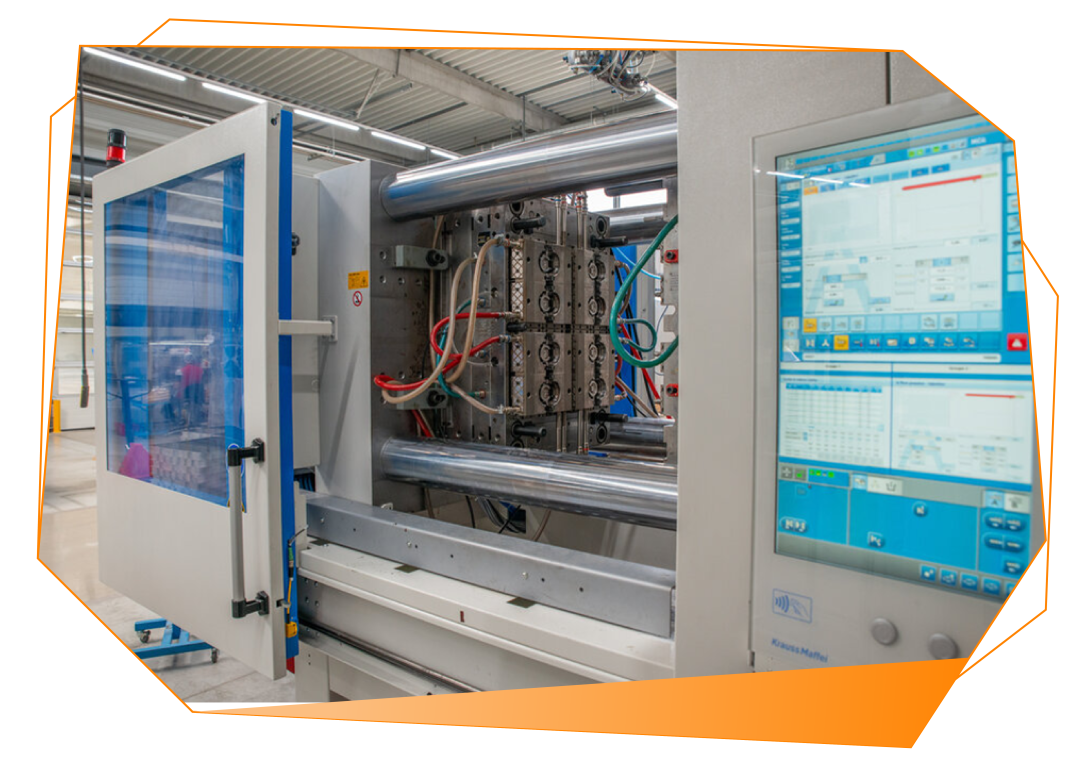

Recently, a brand new KraussMaffeiCXZ 250/1000-750 Multinject Multi-component Injection Molding MachineThe commissioning at Novassu is not only an upgrade of equipment but also an expansion of innovation capabilities. This equipment not only supports two-component sandwich injection molding technology but can also be equipped with a rotary table technology.

The CXZ is equipped with a sandwich mold, providing more possibilities for special forming processes. For example, with the sandwich mold, recycled material can be injected as the inner layer into the surface material layer. This mold solution is highly flexible, not only...Easily switch from sandwich molding process to standard two-color injection molding process.(Without dismantling the injection unit components), it also lays the foundation for environmentally friendly production using a single material in the future.

Thanks to the integration of the rotary table drive system in KraussMaffei equipment, the rotary table mold can easily achieve surface coating or multi-layer injection molding processes. It is this capability to integrate multiple advanced technologies into a single platform that ultimately led Novassu to choose KraussMaffei as its long-term partner. General Manager Gérald Paris stated, "Our business continues to evolve, so we must invest in the most flexible customized solutions. We need a strategic partner who can continually bring cross-industry experience."KraussMaffei is exactly such an ideal partner.”

The core of the sandwich injection molding technology used in the current projects of Novassu is"Inner is recycled material, outer is new material."This technology, although already mature in other industries, has been successfully introduced by Novassu into the high-end cosmetics packaging sector.

This product uses 30% recycled materials and features a crystal-clear cubic bottle cap that embodies creative design while adhering to sustainable principles. Additionally, with the support of KraussMaffei CXZ equipment for third-component configuration, a marble pattern effect can be created inside the bottle cap.

In the cosmetics field, the selection of raw materials is crucial and must be FDA approved, so the scrutiny of recycled materials is particularly stringent. Based on a mature recycling system, materials like PET used in beverage bottles are ideal choices for areas that do not come into direct contact with perfumes or creams.

To this end, Novassu has undergone an important transformation: shifting from relying on chemically recycled ion polymers to standard thermoplastics (such as PET) with more mature physical recycling pathways. This transition not only enhances the recycling potential of the materials but also paves the way for the use of KraussMaffei's fully electric PX series injection molding machines.

Since 2019, all KraussMaffei equipment has been equipped with.APCplus FunctionThis function automatically adjusts the conversion point and holding pressure for each cycle based on the melt viscosity.Ensure stable shot weight.This is particularly evident when dealing with recycled materials, which typically have significant differences between processing batches.

Novassu Morin Day Production Base, with approximately20 KraussMaffei CX and PX series injection molding machinesThe clamping force ranges from 500 to 4,000 kN, producing components approximately 10 to 100 millimeters in size. Gérald Paris has developed an ambitious development plan for Novassu, aiming to further expand the range of injection molding machines. He clearly stated that several processes by KraussMaffei hold great potential for the company, with one becoming a key target for introduction. The newly completed factory last year covers an area of 3,000 square meters, providing ample space for this purpose.

The collaboration between KraussMaffei and Novassu has transcended simple equipment transactions and has become a strategic partnership aimed at jointly addressing industry challenges and exploring cutting-edge solutions. In the future, more remarkable innovative projects will be born from such cooperation.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory