MacroPower by Sets New Benchmark for Cost-Effective Injection Molding with Unique Integrated Frame Design

Brand new integrated MacroPower injection molding machine

On October 15th, the K2025 in Düsseldorf concluded successfully.

Under the theme "The Wise Choice · Intelligent Energy Saving," the global debut of the new integrated MacroPower injection molding machine was completed at booth B22 in Hall 15, showcasing its strength in demonstrating what "systematic time-saving and structural space-saving" means. It became the focal point of attention for many professional visitors during the exhibition.

The MacroPower launched this time has been fully upgraded with an integrated frame in the 400-600 ton clamping force range. Thanks to the design innovation over the traditional split-type equipment, it has become the undisputed "star model" at the K Show.

Entire machine delivery, zero disassembly error: no need to disassemble during transportation, and no need to reassemble upon arrival at the factory.

Compact land use, unleashing space potential: Small and medium-sized factories can also flexibly plan production layouts.

Plug and play, with a surge in production efficiency: fully performance-tested before leaving the factory.

This structure reduces the burden on customers throughout the entire process of "transportation - installation - commissioning," and the on-site discussions remain highly popular.

MacroPower's rotatable injection unit shifts from "equipment convenience" to "ergonomic" design, thoroughly resolving the operational limitations of traditional injection units.

Seamless integration with the control system: paired with the Unilog B8X control system independently developed by Wittmann.

MacroPower adopts an efficient air cooling design, which can significantly reduce operating costs.

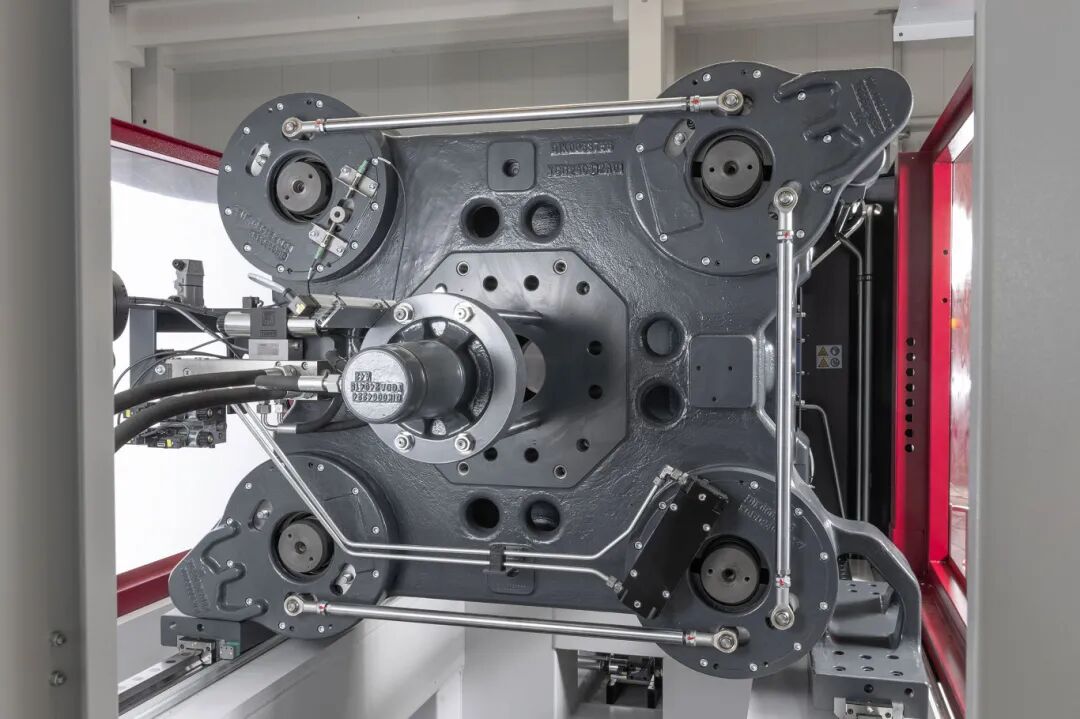

The patented rotary clamping mechanism system is equipped with a single hydraulic cylinder, capable of reliable clamping, featuring a simple structure, low wear, and more hassle-free maintenance.

MacroPower's "energy efficiency advantage" goes beyond energy saving; it lies in "using energy where it matters most."

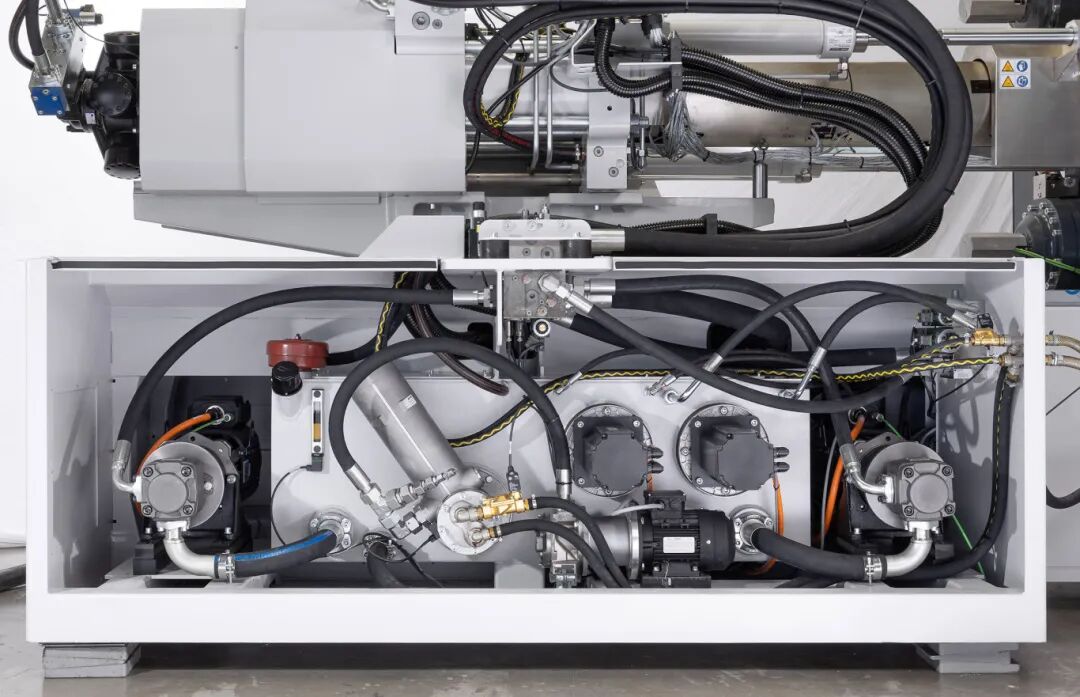

Customized configurations supporting up to four hydraulic units can synchronously drive actions such as core pulling, ejection, and in-mold hydraulic needle valve shut-off.

At the K Exhibition, the MacroPower 500/3400 showcased its hard strength with "fully automated, intervention-free processes," based on the production of HAIBOX logistics turnover boxes using Nordic chemical PP raw materials.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?