Modified eva (part one) | technological trends and business prospects in three major sectors: Photovoltaics, Footwear Materials, and Cables

EVA (ethylene-vinyl acetate copolymer) is formed by the copolymerization of ethylene and vinyl acetate (VA). Due to the incorporation of VA monomers into the molecular chain, EVA is softer, more impact-resistant, more resistant to environmental stress cracking, has better low-temperature resistance, and possesses good optical properties compared to polyethylene. It is non-toxic and widely used. The VA content is the key performance control indicator; the higher the content, the greater the elasticity, density, and adhesion, but the lower the hardness, rigidity, and melting point.

EVA can generally be classified into three categories based on VA content: EVA resin (VA < 40%, mainstream category, commonly used VA contents are 12%, 14%, 18%, 28%, 33%), EVA elastomer (VA 40%-70%), and EVA emulsion (VA 70%-95%). Different categories correspond to different application directions.

01

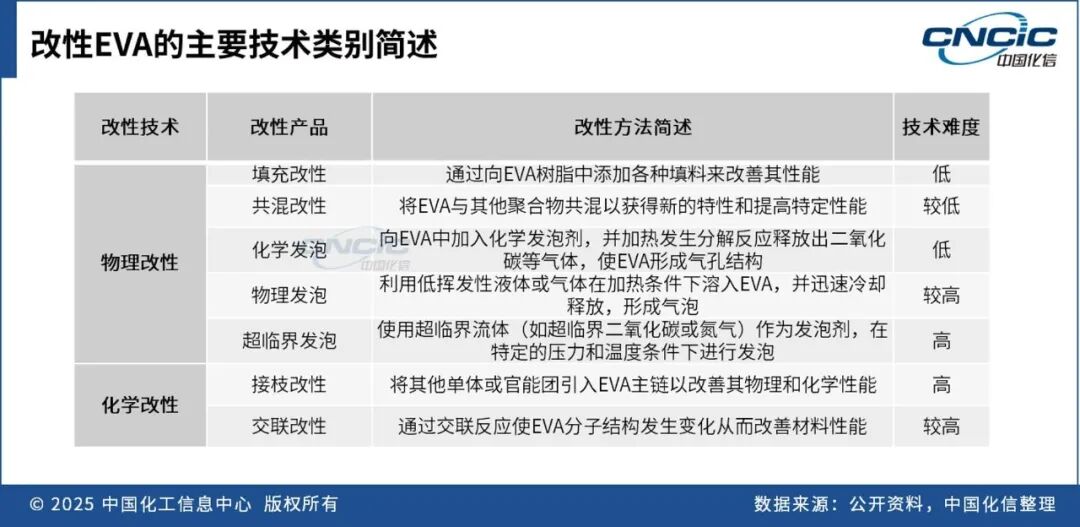

To improve EVA performance and expand downstream applications, a combination of "physical + chemical" modification methods is typically required.

Due to the shortcomings of unmodified EVA, such as low viscosity and poor thermal and mechanical properties, its direct application proportion is small. It needs to be modified to expand its applications, and various downstream fields mostly adopt a modification method that combines "chemical + physical" techniques.The modification methods of EVA mainly include physical modification (such as filling modification, blending modification, foaming modification, etc.) and chemical modification (such as graft modification, crosslinking modification, etc.).

In terms of practical application in various downstream fields, the technology of chemical and physical modification is generally used for EVA modification across different application areas. However, the technical level of modified EVA varies significantly among these fields. Comparatively speaking, the photovoltaic film sector has a higher technical threshold for modified EVA, with more complex modification formulas. In the foam material field, low to medium-end modified EVA products mainly use chemical foaming, which has a relatively low technical level. The cutting-edge physical foaming technology, "supercritical foaming," offers better product performance and higher safety but has a higher technical threshold. The modified EVA technology level in the wire and cable field is relatively low.

02

The performance requirements for EVA modified materials vary across different downstream sectors, and the choice of modification methods and additives also differs accordingly.

Modified EVA material for photovoltaic film

Photovoltaic encapsulation film, as a core material of photovoltaic modules, is crucial in affecting the quality and lifespan of photovoltaic modules. Currently, commercial encapsulation films are mainly categorized into ethylene-vinyl acetate copolymer (EVA) films (transparent EVA films, white EVA films), polyolefin elastomer (POE) films, and EPE (EVA+POE+EVA co-extruded) films. These are primarily made from EVA and POE resins, with the addition of suitable cross-linking agents and anti-aging additives, and are produced into thin films through melt extrusion using calendering or casting processes.

Different photovoltaic encapsulant films can meet the packaging needs of different modules.In terms of single-sided modules,The most economical single-glass modules opt for transparent EVA film for encapsulation on both the upper and lower layers, while white EVA film is used for the lower layer encapsulation to enhance power generation gain.In terms of bifacial modules,Single-layer POE film can be chosen for both upper and lower encapsulation, but it is more costly and less efficient in production. EPE film is used for the lower encapsulation of modules, while transparent EVA is used for the upper encapsulation, which can save costs and improve efficiency. Currently, EVA film dominates the photovoltaic film market due to its low cost, excellent light transmittance, high adhesion strength, and good temperature resistance.

The performance requirements for EVA resin in photovoltaic films are very stringent. Studies have shown that EVA resin with a VA content of 28% to 33% and an MFR of around 40 is most suitable for making encapsulating EVA films. However, because EVA resin has poor creep resistance and thermal stability, it is not suitable for direct use as an encapsulating material for photovoltaic modules. In industrial applications, it is necessary to add crosslinking agents to the EVA film to form a three-dimensional structure in the EVA molecular chain, thereby improving the structural stability of the EVA film. At the same time, the aging resistance, potential-induced degradation resistance, and solar energy utilization efficiency of EVA films also need to be improved through modification to enhance the efficiency of photovoltaic modules. Overall, in the field of photovoltaic films, the modification rate of EVA is nearly 100%.

Creep resistance and thermal stability.During use, the cell temperature of photovoltaic modules may reach as high as 60°C, while the softening point of EVA resin is only around 40°C. This makes EVA films prone to high-temperature creep, leading to slippage between the cells and the glass, severely impacting the safety of photovoltaic modules. Typically, EVA undergoes cross-linking treatment to form a three-dimensional network structure, enhancing the heat resistance and dimensional stability of EVA films to address the issue of high-temperature creep.

Aging resistance performanceThe addition of light stabilizers (such as hindered amine light stabilizers, benzotriazole UV absorbers, benzophenone UV absorbers, etc.), crosslinking agents, and antioxidants (hindered phenol antioxidants, phosphite antioxidants) to EVA films can significantly enhance their aging resistance. Quenchers or free radical scavengers can also be added to block UV light that is not absorbed. Additionally, the incorporation of terpene resin can improve the adhesive strength and aging resistance of EVA films.

Induced degradation performance in terms of counter-electromotive force.The potential-induced degradation (PID) effect in photovoltaic modules can cause power degradation and, in severe cases, module failure. The main causes of the PID effect include the hydrolysis of EVA film under the influence of heat, ultraviolet light, and oxygen, resulting in the production of acetic acid. The acetic acid generated reacts chemically with sodium salts in the glass, causing the migration of Na+, which subsequently leads to PID degradation. Therefore, the modification schemes to enhance the EVA film's resistance to PID effects include: adding polyvinyl alcohol resins to the EVA film to inhibit its hydrolysis reaction; adding acid absorbents to absorb acetate ions produced by EVA degradation; adding activated ion exchange resins to immobilize free Na+; and adding metal ion scavengers to capture Na+ through ion exchange.

Solar energy utilization rate.The conversion efficiency of industrialized photovoltaic cells is currently only 18.0% to 29.0%, with theoretical values ranging from 26.8% to 30.0%. Photovoltaic cells can absorb ultraviolet light (wavelengths between 300 and 400 nm) but cannot fully utilize it. Photoconversion-type EVA films can absorb ultraviolet light and convert it into visible light for use, effectively enhancing the solar energy utilization rate of the modules. Commercial photoconversion agents include organic dye phosphors, inorganic metal oxide phosphors, and rare earth complexes.

Thermal conductivity======Photovoltaic module cells are relatively thin, and the heat concentrated in the middle layer is primarily dissipated by the upper and lower components. Therefore, enhancing the thermal conductivity of the EVA film is of significant importance. Adding specific mass fractions of materials such as aluminum oxide or zinc oxide to the EVA film can effectively improve its thermal conductivity.

Adhesion performance======EVA material is a weakly polar polymer, and its adhesion strength with photovoltaic glass is low, which can lead to delamination issues during long-term use. On one hand, as the VA content increases, the number of active groups in the EVA film gradually increases, improving its adhesion performance and peel strength at room temperature. On the other hand, the adhesion performance of the EVA film can be enhanced by adding silane coupling agents such as KH570, amino group-containing coupling agents (KH550, KH792, Z-6032), and tackifying resins (such as terpene and terpene-phenolic resins, rosin and modified rosin resins, modified petroleum resins).

Traditional photovoltaic modules are primarily white, but in locations such as distributed power stations, white can easily cause light reflection and result in light pollution. Therefore, some cities require that photovoltaic modules must use dark-colored panels, such as dark blue, dark gray, or black. The photoelectric conversion efficiency of dark-colored photovoltaic modules is generally 2%-6% lower than that of conventional white photovoltaic modules.

In terms of technological development,As the application environments for photovoltaic modules become increasingly diverse, the market demands higher requirements for their lifespan and cost. The varying conditions of temperature and humidity in different regions impose higher demands on the performance of EVA films. Therefore, the types of film products will become more diverse, and the custom development of high-performance EVA films will become a future development trend. In the short term, the modification direction of EVA in the photovoltaic field will still focus on the research of modified formulations, effectively reducing production costs while ensuring that the performance of the photovoltaic films meets downstream application requirements.

Foaming material using EVA modified material

EVA foam material, due to its lightweight, softness, good elasticity, high abrasion resistance, and good transparency, is often used in the production of shoe soles, particularly the midsoles of sports and casual shoes. In addition to shoe midsoles, EVA foam material is also used in the manufacture of insoles and shoe linings, further enhancing the comfort and functionality of shoes.

The preparation process of foamed materials can be divided into two basic categories: chemical foaming and physical (supercritical fluid) foaming. Under these two categories, the process can be further subdivided into sheets, beads, etc. From the perspective of finished product performance, physical (supercritical fluid) foamed materials are far superior to chemical foamed materials.

The traditional EVA foaming technology primarily uses EVA as the main raw material, adding fillers, foaming agents, cross-linking agents (also known as coupling agents), foaming promoters, lubricants, and other additives. It is then processed through mold compression foaming or injection foaming. The production process mainly includes three steps: granulation, blending, and foaming. Different formulations can produce EVA foam materials with varying properties after foaming.

Physical foaming, also known as supercritical fluid foaming or supercritical foaming, is currently the most advanced industrial EVA foaming technology. It uses supercritical fluids, such as supercritical carbon dioxide or nitrogen, as the foaming agent under specific pressure and temperature conditions. The modifying additives used are basically the same as those in chemical foaming technology. Compared to chemical foaming, the foam materials produced by the supercritical foaming process have finer and more uniform cells, and superior properties in terms of rebound, toughness, lightweight, and durability. Supercritical foaming is generally superior to chemical foaming in every aspect. However, correspondingly, supercritical foaming requires much higher standards for equipment and process control, leading to significantly higher production costs than chemical foaming. Supercritical fluid foaming technology has relatively matured domestically, but its main challenge lies in controlling the foaming rate, ensuring that the dimensions of the foamed product are as consistent as possible with the final product, thereby improving yield rates and reducing material waste. Due to the relatively higher production costs and the more precise and complex process requirements for midsole design and production, there are certain barriers to its widespread market application. It is currently mainly used in the mid-to-high-end footwear sector.

In terms of foaming technology, the overall market share of physically foamed shoe materials is still relatively small (10%-20%). However, the performance indicators of physically foamed products are superior. Additionally, physically foamed products are environmentally friendly and safe, as they do not produce harmful substances from the chemical reactions of azo foaming agents. This reduces the potential hazards for footwear industry workers and addresses the frequent consumer complaints about unpleasant odors from shoe soles. Defective physically foamed midsoles can also be recycled and reused; after being crushed and mixed, they can still serve as harmless raw materials for shoe material foaming or other industries.Leading enterprises in the shoe material industry, such as Taiya Group and Jinjiang Guosheng, are optimistic about the physical foaming market. In the shoe material industry, supercritical fluid technology (physical foaming) is gradually showing a trend of replacing traditional chemical foaming processes.

03

EVA Modified Material for Electric Wires and Cables

EVA is a halogen-free polar polymer that is compatible with various materials. It exhibits excellent mechanical and physical properties, electrical properties, and exceptional mixing and extrusion processing performance. It is an indispensable base material for manufacturing high-voltage cable shielding materials, low-smoke halogen-free flame retardant materials, and oxygen barrier materials.The vinyl acetate content in EVA resin used in wires and cables is generally between 18% and 40%.

In terms of cable shielding materials, EVA is an ideal choice for the base resin of semiconductive shielding materials because it can accommodate a large amount of conductive fillers such as conductive carbon black without affecting its mechanical and processing properties. In power cables, EVA is used for conductor shielding and insulation shielding to alleviate the concentration of electric field stress within the cable, eliminate the effects of conductor stranding, improve the radial distribution of the electric field within the cable, and enhance the electrical strength and service life of the cable.

Oxygen barrier material======To make the flame retardant performance of halogen-free low-smoke flame retardant cables more reliable, an oxygen barrier layer structure is added, that is, an oxygen barrier layer made of special oxygen barrier materials is added between the cable insulation layer and the sheath layer. When the cable encounters open flames, the oxygen barrier material can release a large amount of moisture to lower the ambient temperature and form a non-melting, non-combustible aluminum oxide hard shell, isolating the insulating organic material from contact with external air. This ultimately allows the cable to achieve self-extinguishing, greatly improving the flame retardant level to reach Class A flame retardant standards. Additionally, cables using an oxygen barrier layer structure can utilize ordinary insulation materials, thus avoiding adverse effects caused by the addition of inorganic flame retardants and smoke suppressants. Due to EVA's compatibility with various materials, including halogen-free flame retardants, EVA is widely used as a base material for preparing high flame-retardant oxygen barrier layers.

Halogen-free flame retardant materials.Due to the low melting temperature, good fluidity, polarity, and halogen-free nature of EVA, it is compatible with various polymers and halogen-free flame retardants and is widely used in low-smoke halogen-free flame retardant cable materials. However, since the limiting oxygen index of EVA is only 17% to 19%, it is classified as a flammable material, significantly restricting its application and development in flame-retardant cables. Therefore, flame retardant modification of EVA is necessary. Commonly used halogen-free flame retardants for EVA cable materials include metal hydroxides (magnesium hydroxide, aluminum hydroxide), intumescent (phosphorus, nitrogen-based), boron-based, and silicon-based flame retardants. Intumescent flame retardants are expensive and mainly used in high-value-added specialty cable materials. In halogen-free flame retardant cable materials, they are generally used in combination with metal hydroxide flame retardants, achieving a better low-smoke halogen-free flame retardant effect.

In recent years, developed countries have been promoting the concept of "green environmental protection" in the electrical and electronic industry. With the continuous rapid development of China's economy, the flame retardant requirements for cables used in many newly built high-rise buildings, tunnels, subways, large ships, automobiles, nuclear power plants, offshore oil platforms, and other modern facilities are increasingly stringent, and they are all required to use environmentally friendly halogen-free flame retardant wires and cables. Due to its excellent comprehensive performance, EVA will continue to serve as an important flame retardant matrix material for low smoke halogen-free cable materials. However, because of EVA's relatively low insulation performance, the industry's research focus will be on improving the insulation performance of EVA-based low smoke halogen-free flame retardant cable materials. In terms of flame retardants, the surface modification and particle size refinement of metal hydroxides will also become key research directions for high-end domestic metal hydroxide flame retardants. Some companies are continuously developing new halogen-free flame retardants, such as Taihu Yuanda Company, which is developing a new halogen-free flame retardant that can achieve UL94 V-0 grade flame retardant performance for cable insulation materials, with an oxygen index OI% ≥28%, making it safer and more environmentally friendly.

Overall,The modification rate of EVA used in the fields of photovoltaic film, foam materials, and wire and cable materials is relatively high.Different application fields have varying performance requirements for EVA, leading to diversification and customization in the development of photovoltaic encapsulation films as a future trend. Therefore, photovoltaic encapsulation film manufacturers will further optimize the EVA modification formulations used in photovoltaic films based on the performance requirements of end products, aiming to enhance performance while reducing production costs.

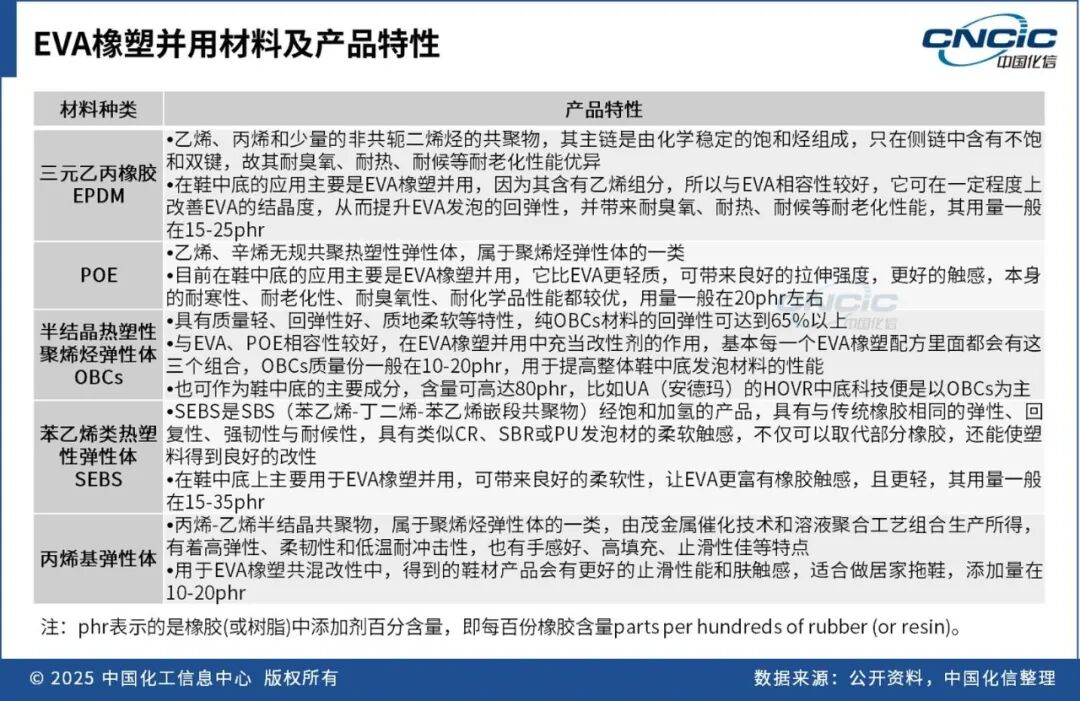

EVA foam shoe material.The new demands for reducing material hardness, improving resilience, and decreasing compression deformation have made EVA rubber-plastic blending a key focus in industry research. Products made using supercritical physical foaming technology are more environmentally friendly, have superior performance, and higher recycling rates. Therefore, supercritical physical foaming technology is gradually replacing traditional chemical foaming technology, with its application share increasing.

EVA modified material for wires and cables.Environmentally friendly halogen-free flame retardants and low-smoke halogen-free compatibilizers are key research and development focuses for leading companies.

In summary, it is recommended that EVA modified material manufacturers in related fields pay attention to the development trends and performance requirements of end products, enhance technical capabilities, and optimize EVA modification formulas. This will improve the performance of EVA modified materials while reducing production costs and increasing product competitiveness.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory