Nylon Wear-Resistant Modification Scheme Without PTFE

With the increasing global regulatory tightening on per- and polyfluoroalkyl substances (PFAS), finding and using materials that do not contain PTFE (polytetrafluoroethylene, a typical PFAS) has become an urgent task for many manufacturers. Avoiding PTFE in nylon modification, particularly due to environmental and regulatory considerations regarding PFAS, is completely feasible and is becoming an increasingly common practice.

PTFE (polytetrafluoroethylene) is the most well-known member of the PFAS family.Due to its unique chemical structure (extremely strong C-F bond), it is extremely difficult to degrade in the environment, has potential bioaccumulation and toxicity, and is therefore increasingly strictly regulated worldwide.

In nylon modification, PTFE is often used asLubricants/Wear-resistant agentsTo reduce the friction coefficient and improve wear resistance. Therefore, the core of avoiding PTFE is to find substitutes that have the same or similar functions.

For the demand of nylon wear resistance modification without the use of PTFE, there are currently several mature and effective alternatives, mainly including the use of other solid lubricants, specific polymer alloys, and improved preparation processes.

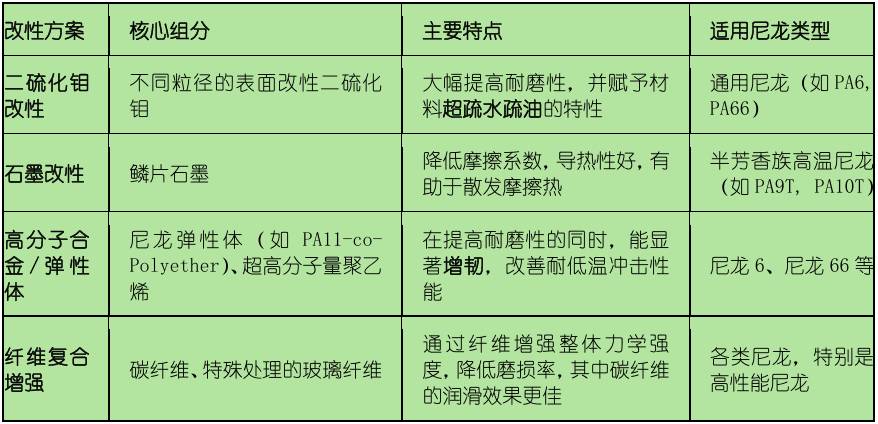

The table below summarizes several mainstream PTFE-free wear-resistant modification solutions.

Other feasible solutions

Silicone series

One of the most mainstream and mature alternatives to PTFE at present.

Silicone masterbatch/silicone oil:

Mechanism:During the processing, silicone migrates to the nylon surface, forming an extremely thin, continuously self-repairing lubricating layer.

Advantages:

Significantly reduce the coefficient of friction (comparable to or even better than PTFE).

Improve wear resistance.

This does not affect the mechanical strength of the nylon itself.

Good thermal stability.

Not inherently a PFAS, environmentally friendly.

Notice:It may have a slight impact on subsequent printing and bonding processes, which needs to be evaluated.

② Organic silicone resin micro powder:

Mechanism:Uniformly dispersed as a solid lubricant in the nylon matrix.

Advantages:Provides long-lasting lubrication effects with minimal impact on surface treatment.

Series 2: Wax

Wax is another type of classic, efficient, and environmentally friendly lubricant.

① Polyethylene Wax (PE Wax):

Mechanism:After melt processing, wax will precipitate to the surface of the product, forming a lubricating layer.

Advantages:Low cost, good effect, strong versatility.

Polyamide wax:

Mechanism:It has better compatibility with the nylon matrix, providing a more stable balance of internal and external lubrication.

Fischer-Tropsch Wax

Mechanism:Narrow molecular weight distribution, high hardness, high lubrication efficiency.

Advantages:It has excellent gloss and mold release effect.

3. Inorganic nanoparticles

Nano silica, nano alumina, etc.

Mechanism:By forming a "rolling bearing" effect or reinforcing the matrix at the friction interface through nanoparticles, wear is reduced.

Advantages:Using less dosage may enhance wear resistance while possibly increasing the material's rigidity and strength.

Disadvantages:The dispersion process requires high standards, and its effect on reducing the coefficient of friction may not be as significant as that of silicone or wax.

Plan Selection and Process Key Points

When selecting and implementing these plans, there are some key points to consider:

Select materials based on working conditions.

For scenarios requiring chemical resistance, hydrophobicity, and oleophobicity (such as liquid packaging and chemical components), the molybdenum disulfide modification solution has obvious advantages.

In areas requiring high mechanical strength and high temperature resistance (such as automotive engine peripheral parts), carbon fiber or graphite reinforced semi-aromatic nylon (such as PA9T, PA10T) is an ideal choice.

If a product needs to withstand low-temperature impact or requires high toughness (such as outdoor equipment or flexible components), a nylon/polyolefin alloy solution is more suitable.

Focus on process details:

Surface treatment is important: the surface treatment of molybdenum disulfide and glass fibers before use (such as coupling agent treatment) can significantly improve their compatibility with the nylon matrix and enhance the modification effect.

Mixing sequence of additives: In twin-screw extrusion granulation, it is generally recommended to introduce the base resin and powder additives such as wear-resistant agents from the main feed port, while fibrous reinforcement materials should be fed from the side feed port. This approach can better control the fiber length and reduce performance losses.

Control processing temperature: Different nylons and modifiers require matching processing temperatures. For example, the extrusion temperature of modified high-temperature nylon (such as PA9T) may reach 270-330℃, while the processing temperature of some nylon alloys may be in the range of 200-230℃.

When selecting specific alternative materials, it is essential to first clarify what the most critical performance indicators of your product are (such as chemical resistance, high-temperature resistance, low friction, or mechanical strength). Typically, one alternative material cannot replicate all the advantages of PTFE, but as long as it meets the core application requirements, it is a viable choice. Evaluate the total cost: PFAS-free materials may bring cost pressures. When assessing, consider not only the price of the materials themselves but also the impact on production efficiency, product lifespan, maintenance costs, and compliance advantages. Focus on sustainability: Choosing more environmentally friendly, recyclable materials, or those that can help extend the lifespan of the end product is not only a response to current regulations but also meets the growing customer concern about the carbon footprint of products.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory