Only One Mass Production Overseas! How Big Is The Market Space For This Eco-Friendly Additive After Breakthroughs In Domestic Technology?

Ethylene Maleic Anhydride Copolymer (EMA), with CAS number 9006-26-2, is a product obtained from the alternating copolymerization of ethylene and maleic anhydride at a molar ratio of 1:1, with a maleic anhydride content of >78%. Due to the presence of a large number of highly reactive cyclic anhydride groups in its main chain, this substance readily reacts with alcohols to form esters and with amines to form amides.

Maleic anhydride copolymerizes with ethylene through chemical bonds, making EMA completely different from maleic anhydride grafts available in the market. It exhibits extremely high thermal stability, with a softening point >150°C and a decomposition temperature >300°C. It does not have the migration of free maleic anhydride, nor does it have odor or VOC concerns. It is a high-efficiency, safe, and environmentally friendly specialized chemical and eco-friendly high-activity additive. Currently, its main downstream application is in glass fiber sizing agents.

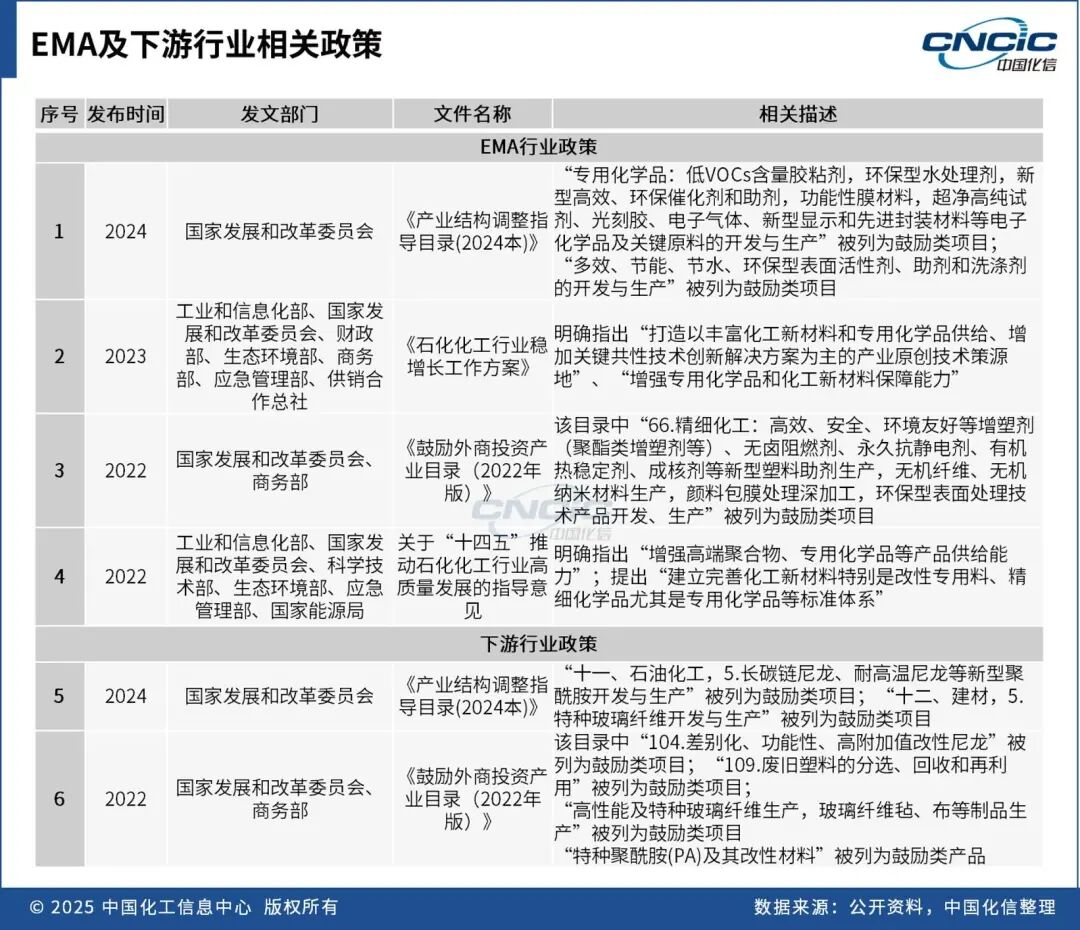

In recent years, China has introduced several policies to encourage the development of related industries and simultaneously support downstream industries of EMA.Special glass fiber, modified nylon specialty materials, and recycled plastics.Developing related industries.

01

EMA's new invention introduces co-catalysts, which improve monomer conversion rates and production efficiency, making it more suitable for industrial production and promotion.

Traditional EMA production technology mainly uses the method of polymerization under high temperature, high ethylene pressure, and long duration. The production conditions are quite stringent, requiring high demands on equipment, resulting in higher production costs, which limits its production scale and practical applications. However, in June 2023, the team of Cui Dongmei, Li Shihui, and Cai Ling from the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, was granted an invention patent titled "A High-Efficiency Preparation Method for Ethylene-Maleic Anhydride Alternating Copolymer."The patent introduces Lewis acid cocatalysts into the copolymerization catalyst system, significantly enhancing the copolymerization activity of ethylene and maleic anhydride.By lowering the polymerization temperature, shortening the polymerization reaction time, significantly reducing the ethylene pressure, decreasing energy consumption, avoiding high-pressure production equipment, and enhancing the safety factor during production operations, the monomer conversion rate and production efficiency are improved, making it more suitable for industrial production and promotion applications.

Currently, Vertellus is the only overseas supplier of EMA products, with production capacity highly concentrated and a tight balance between supply and demand. The main product grades include ZeMac E60 (weight average molecular weight 60,000), ZeMac E400 (weight average molecular weight 400,000), and ZeMac E10 (weight average molecular weight 10,000). Among them, E60 is the mainstream grade and can be applied in various fields.

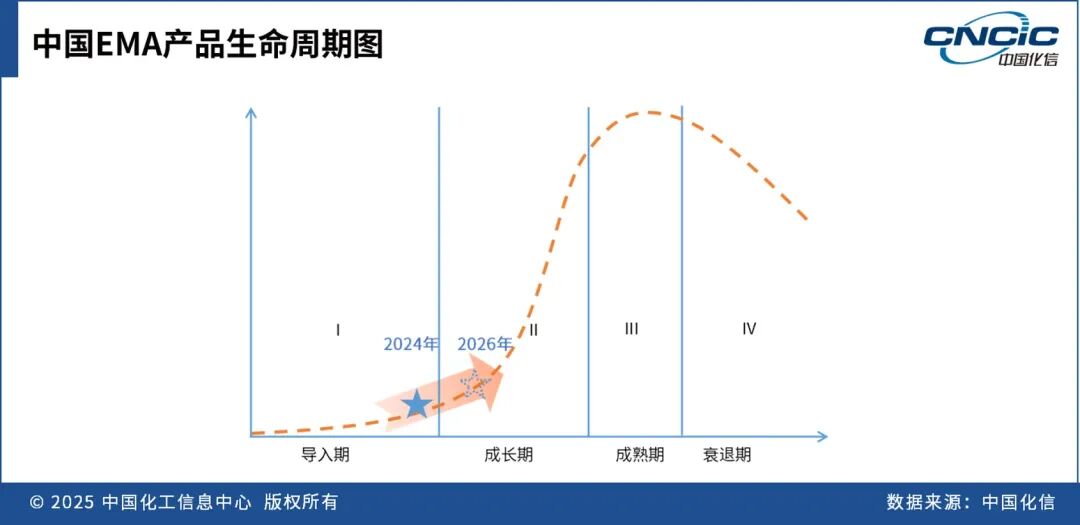

As of 2024, there are no large-scale EMA production enterprises in China. In recent years, some domestic companies have accelerated the research, testing, and industrialization of EMA products. It is expected that in the future, some EMA products produced by domestic manufacturers will gain recognition from downstream customers, enter the market, and achieve partial import substitution.

02

EMA is widely used and strongly driven by demand in the fiberglass sector, with future consumption growth expected.

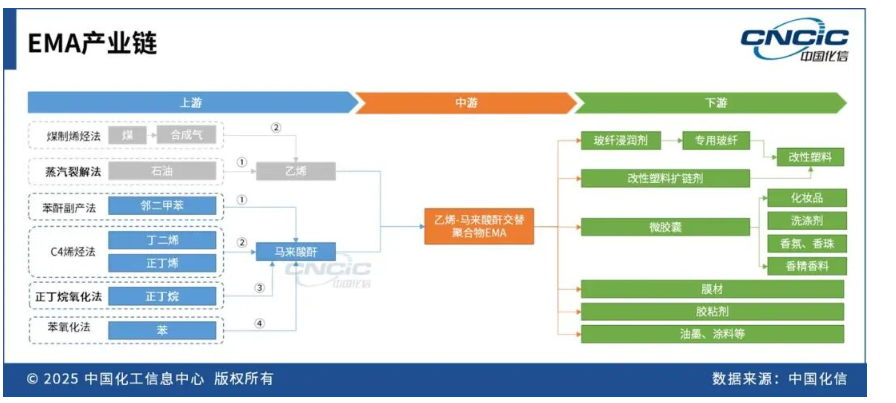

In terms of downstream applications, due to the high maleic anhydride content and inherent solubility of EMA, it is currently widely used in various fields such as fiberglass sizing agents, plastic modification chain extenders, microcapsules, membrane materials, and adhesives.

Glass fiber wetting agent field.EMA, as a film-forming agent component in fiberglass sizing agents, can enhance the compatibility between glass fibers and resin, thereby significantly improving the mechanical properties and heat resistance of composite materials. As an essential raw material for fiberglass sizing agents used in special glass fibers for nylon and polyester modification, EMA is stable and efficient, having been verified by the market. Other similar products (such as ethylene-propylene-maleic anhydride copolymers, isobutylene-maleic anhydride copolymers, etc.) have inferior reactivity and stability compared to EMA when used as raw materials for fiberglass sizing agents. The resulting fiberglass products cannot meet the performance indicators of special glass fibers. Therefore, EMA products are favored by manufacturers of fiberglass sizing agents.

Microcapsule fieldEMA molecules serve as excellent surfactants. On one hand, EMA copolymers can act as emulsifiers or size regulators for microcapsules, forming highly stable emulsion systems and controlling the particle size and distribution of microcapsules, thereby increasing the stability of microcapsule quality. On the other hand, they can also participate in the reaction of microcapsule wall materials, providing better mechanical, thermal, chemical, and hydrolysis resistance properties, allowing the microcapsule wall to be made thinner. Microcapsules of the same size can encapsulate more functional ingredients, greatly enhancing the efficiency of the microcapsules. The end-use can be mainly applied to downstream fields such as cosmetics and detergents. Currently, microcapsules in China are at the stage of technological breakthrough, and the future demand for EMA is expected to be high, with a very broad development space.

Membrane materials field.EMA has strong molecular adhesion properties and high environmental friendliness, with low difficulty in recycling. Therefore, EMA can be used as a membrane material, and in the future, EMA emulsion is expected to replace PVDC coating materials as high barrier film materials. At the same time, EMA can serve as an adhesive layer material in multilayer co-extruded composite films, providing excellent adhesion. However, given the currently high price of EMA materials, the development of such applications is low, and most manufacturers use ethylene-maleic anhydride graft copolymer as the adhesive layer material. It is expected that as domestic EMA production capacity comes online and prices decrease, the application of EMA in the membrane material field will further expand.

Modified plastics field.The EMA main chain contains a large number of highly reactive cyclic anhydride groups, which can easily undergo chain extension reactions. It exhibits excellent reactivity with polyamides containing -NH2 groups and polyesters containing -OH groups, enhancing the molecular weight, mechanical properties, and freeze-thaw stability of the aforementioned products.

Adhesive fieldEMA can be added to polyurethane adhesives and acrylic adhesives to improve bonding performance and thermal stability. It can also be used as an auxiliary agent for pressure-sensitive adhesives in the screw adhesive field.

In recent years, thermoplastic composites (FRTP) have shown strong performance in the automotive and home appliance composite materials market, driving structural undersupply of chopped strand fiberglass products in multiple global markets, which in turn has led to rapid growth in demand for EMA products. In 2024, the global consumption of EMA is approximately 1,900 tons, with the highest consumption in the fiberglass sizing agent field, followed by the film and adhesive sectors. Consumption in areas such as modified plastic chain extenders, microcapsules, and other fields remains to be developed.In 2024, China's EMA consumption is approximately 1250 tons, with the glass fiber sector accounting for about 1200 tons, making up a staggering 94%.

In the future, with the rapid development of short-cut fibers in thermoplastic composites (FRTP) and technological advancements in film materials and microcapsule fields, the demand for EMA products is expected to continue growing at a high rate. The glass fiber sector remains the main driver for the growth in demand for EMA products. Moreover, although the current demand base for EMA products in emerging application areas such as film materials and microcapsules is still relatively small, if the price of EMA products decreases due to domestic alternatives, the demand in these fields will also be considerable.

Huaxin's Perspective

Currently, the global EMA market is dominated by Venator, with tight product supply. Due to limited production capacity, the downstream market has not been effectively developed.As a high-performance green environmental protection additive, EMA products are currently mainly used in the field of fiberglass wetting agents, with a large and rapidly growing demand. In the future, there is also significant market potential in areas such as microencapsulation, membrane materials, and chain-extending agents for modified plastics.The domestic EMA products are still in the introductory phase, highly reliant on imports, posing a supply interruption risk. For China, it is considered a "choke point" product, and it is necessary to achieve import substitution as soon as possible.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories