Project Financing 130 Million Yuan Faces Opposition: United States Chemical Recycling Plant Encountering Strong Local Resistance!

The incident began on July 18th when residents of the Rohnert Park community received a notification that a chemical recycling facility operated by Resynergi was applying for an operating permit. They received the notification because the facility is less than 1,000 feet (approximately 300 meters) from a local high school.

Brian Bauer, co-founder and CEO of Resynergi, stands in front of the plastic pyrolysis reactor slide in Rohnert Park.

Since 2015, Resynergi has been developing a modular "advanced microwave-assisted pyrolysis" system that can process over four tons of plastic daily, converting it into 69% pyrolysis oil, which can be refined into new plastics or fuels. The remaining 31% of the plastic is converted into gas, wax, and coke.

Resynergi consistently asserts that its technology is safe and reliable. The company uses microwave energy to decompose plastics in an anaerobic micro-vacuum system. According to the company, the non-condensable gases remaining from this process are sent to a thermal oxidizer, which has a removal efficiency rate of up to 99.98%.

Previously, the company built a pilot plant in Santa Rosa, California, to initiate its first commercial-scale recycling facility in the state. Earlier this year, the company also received an investment of $18 million (approximately 130 million RMB) and planned to build in Rohnert Park. However, due to opposition from residents, the project may be further delayed.

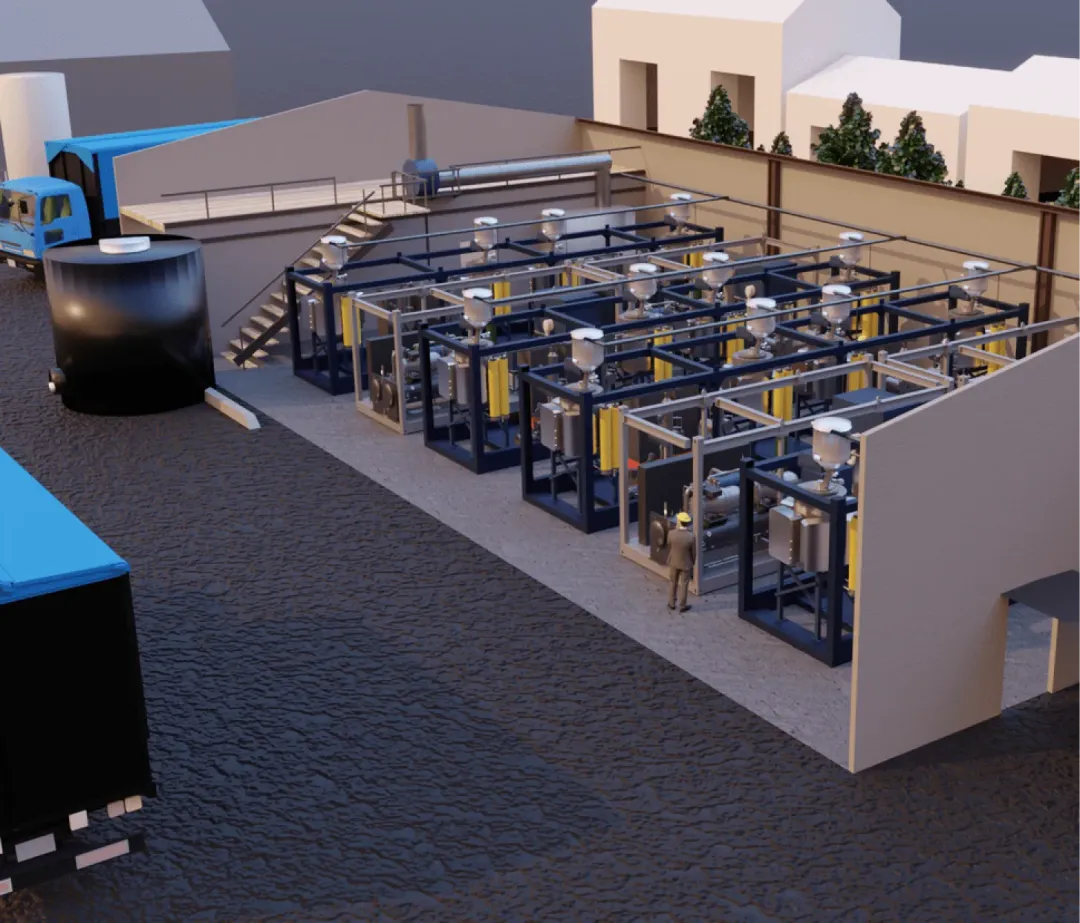

Resynergi's modular plants are designed to decentralize the collection and processing of plastic waste, occupying a smaller footprint than typical chemical recycling facilities. They utilize Continuous Microwave Assisted Pyrolysis (CMAP) technology provided by partner Lummus Technology. Each module is designed to process 20 to 40 tons of plastic waste per day (up to 50 tons) using microwave reactors. Resynergi's modules have a smaller footprint and faster conversion times, offering a cost-effective and environmentally friendly alternative to traditional recycling methods.

Modular equipment

Modular Integrated Device

Image source: resynergi

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?