Recycled plastics have odors and release vocs, adsorbents and antibacterial agents used to solve this, building a beautiful earth together with green and low carbon

In the production process, recycled plastic releases a significant amount of unpleasant gases. In order to reduce these unpleasant gases and lower VOCs, various VOCs odor removal treatment processes have been gradually applied in the manufacturing phase.

The new modified deodorant, with its core advantages of large specific surface area and strong adsorption capacity, can achieve strong physical adsorption of aldehydes, ketones, amines, organic sulfides, and organic chlorides through the ions between its mineral layers, and complete partial chemical decomposition. This characteristic ensures that the deodorant does not cause secondary volatilization issues due to temperature rise during raw material processing, making it particularly suitable for resin systems such as PP, PE, PVC, PA, and ABS. It not only has a significant effect and is easy to operate but also can be evenly dispersed in the resin and possesses good thermal stability, showing outstanding application performance.

The new EU automotive proposal also clearly defines the important role of recycled plastics: as a key direction in the circular economy field, recycled plastics have dual value in reducing carbon emissions and pollutants. They are not only an important means to curb plastic pollution but also part of the national strategic reserves, which will help achieve global carbon peaking and carbon neutrality targets.

01

Association between VOCs and odors

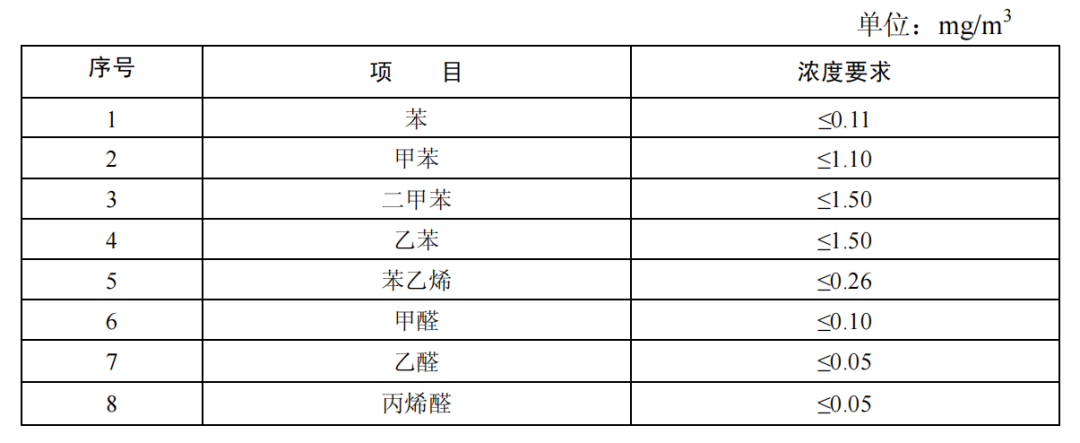

As is well known, plastic products used in cars and indoors can emit odors and release VOCs.Currently, the relevant national and industry standards clearly specify the types and concentrations of harmful volatile organic compounds.There is no unified standard for odor regulation, and the correlation between VOCs and odors is unclear. For example, volatile organic compounds that are highly hazardous to human health are not necessarily the substances that cause odors in products, such as benzene, toluene, ethylbenzene, formaldehyde, etc. When an odor can be detected, its concentration is already dozens of times above the standard limit!

Graph | Requirements for Concentration of Organic Compounds in Vehicle Interior Air Source | GB/T 27630—2011 Guidelines for the Evaluation of Air Quality in Passenger Vehicle Interiors

Additionally, there are some volatile organic compounds with extremely low odor thresholds present in cars and indoors, such as acetaldehyde, amines, and sulfur-containing compounds, which can produce a noticeable smell even in very small amounts.

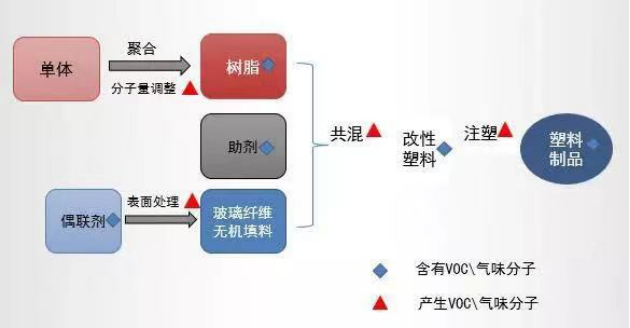

In addition to the odor threshold and odor type of VOCs themselves, different people have significant differences in their perception of odors. The smell emitted by plastic products that we usually detect is composed of various molecules, and its generation process is illustrated in the following diagram.

Figure | Odor generated during plastic products production

02

Waste plastic VOCs deodorization process

As the demand for reduced VOCs and low odor in waste plastics increases from downstream applications, different processes for removing VOCs and odors are applied in manufacturing.

Cover and conceal

The method of directly adding powdered or solvent-based fragrance compounds is used to blend various scents and produce new ones to reduce irritation. This method merely masks the odor of VOCs, making it difficult to last, as VOCs still exist.

Chemical deodorization

The method involves directly adding reducing agents, chelating agents, or decomposing agents to convert VOCs into less volatile or harmless substances through chemical reactions. This method has limited applicability, high costs, and can easily lead to other side reactions that may affect the physical properties of materials.

Dehumidification drying

Under conditions of high temperature and high vacuum, organic small molecules are removed using negative pressure. This method is energy-intensive, requires high investment, has high production costs, and affects material performance.

Gas lift method

The inert gases such as water, nitrogen, and carbon dioxide are injected into the polymer melt through gasification or water atomization to remove organic volatile small molecular substances. This method has difficulties in adding gas agents, requires high equipment investment, involves complex processes, has poor compatibility with the resin matrix and VOCs, and has limited removal effectiveness.

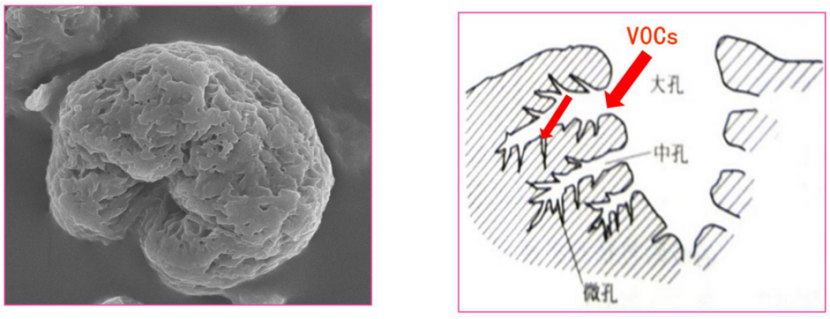

Adsorption method

Under high temperature conditions, the pore size of the deodorizer is opened to adsorb free volatile small molecules for capturing and encapsulating, thereby reducing odor. This method has a simple processing technique, and waste plastic can be added beyond the formula, mixed evenly, without affecting the performance of the material itself, with an addition amount of 0.3-0.6%.

Diagram | Jiahe deodorant's unique pore structure

03

Jiahe Deodorizer

Ningbo Jiahe New Material Technology Co., Ltd.The deodorant is made using selected inorganic silicate with a single-pore structure as raw material, processed through a special technique. Due to its unique molecular structure, the product can effectively inhibit and absorb irritating odors from various chemicals and other unpleasant smells. It can also absorb harmful volatile residue components such as benzene, ammonia, formaldehyde, chlorine, etc.

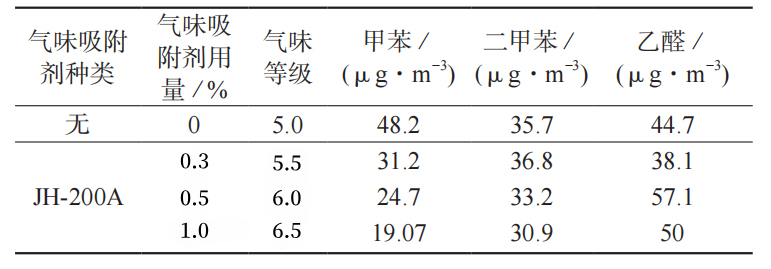

Table: Effects of Jiahe Deodorant and Its Dosage on the Odor and VOCs Content of PP Composites

From the table, it can be seen that with the increase in the amount of odor adsorbent, the odor of PP composites is significantly improved, and the VOCs content is significantly reduced.When the dosage of JH-200A is 0.5%, the odor level improves by 0.5-1 grade compared to before.In a high-temperature environment, JH-200A can physically adsorb small molecules volatilized from PP composite materials, thereby reducing odor and VOCs.

In addition to effectively addressing the issue of odor in plastic products, endowing them with antibacterial and mildew-proof functions has also become an important direction for enhancing product added value, meeting consumer upgrades, and health demands. Among the numerous antibacterial solutions,Inorganic Antibacterial Agent High heat resistance, good safety, long shelf lifeThe characteristics mentioned above have led to its wide application in the plastics industry.

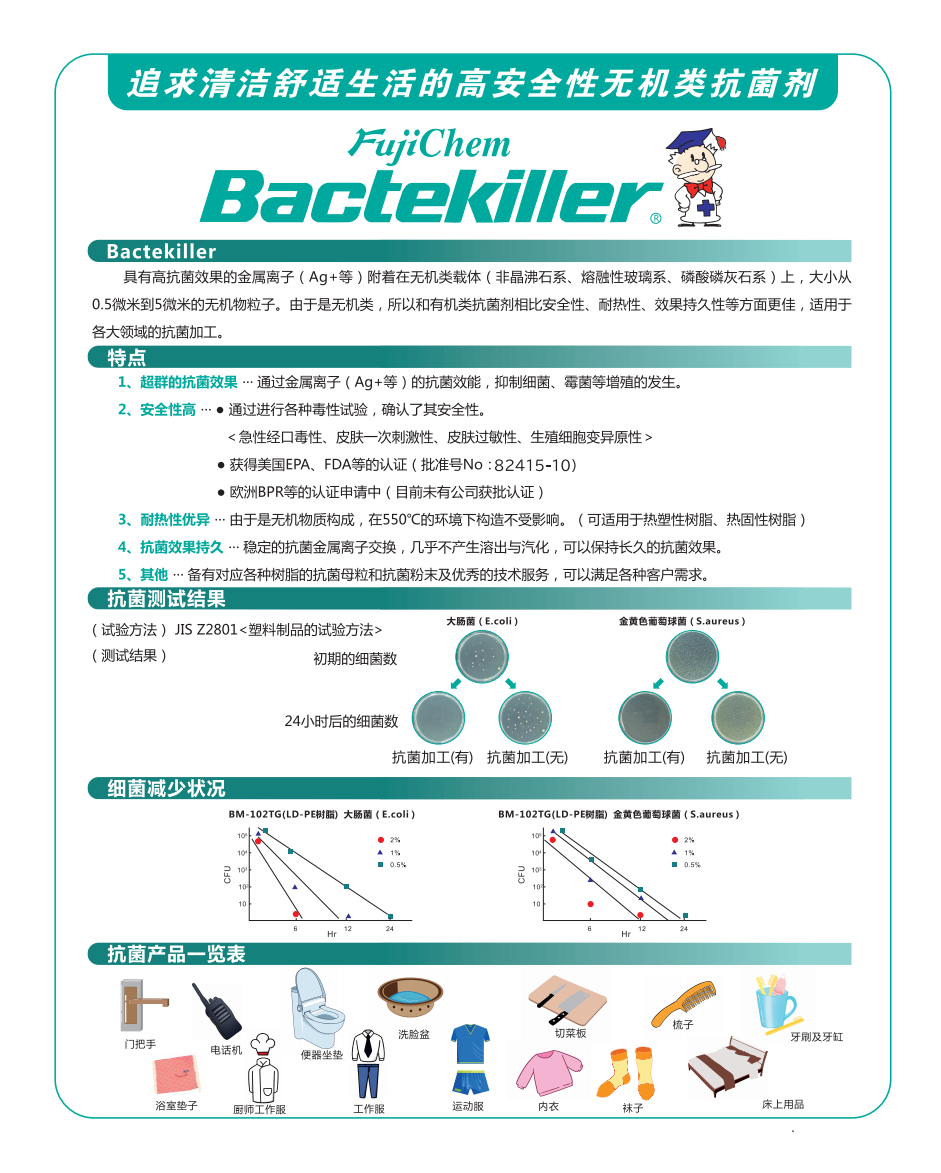

Among them,Bactekiller Series Inorganic Antibacterial AgentIt is one of the representative products in the market. This series achieves long-lasting antibacterial and anti-mold effects by releasing antibacterial metal ions such as silver (Ag⁺) and zinc (Zn²⁺), which disrupt the cell membranes or protein structures of bacteria and mold.

According to different application requirements,Bactekiller offers a variety of product models.For example:

BM-104KJ is a zinc-based antibacterial agent.It appears as a white powder with an average particle size of approximately 1.5μm. It has a broad inhibitory effect on molds and bacteria, with low risk of discoloration and good durability. It is registered in the SIAA (Society of International sustaining growth for Antimicrobial Articles) list of inorganic antifungal agents and complies with the requirements of China's food contact material standard GB9685-2016. Test data shows that adding 0.3%-0.5% to ABS resin achieves an antibacterial activity value (R) of 2.0 or higher against E. coli and Staphylococcus aureus; when added at 2.0% to HIPS resin, the 28-day antifungal test results in a mold resistance rating of 0 (i.e., no mold growth observed).

BM-502KEThis belongs to the silver-zinc composite system product, also a white powder, with an average particle size of about 6μm. While maintaining the high antibacterial efficiency of silver-based antibacterial agents, it further optimizes water resistance and light resistance, significantly reducing the risk of silver ions discoloration. This product is suitable for various resins such as PP and PE, with a recommended addition amount of 0.3%-0.5%. It has been successfully applied in kitchenware, home appliances, and fiber products.

From a technical perspectiveInorganic antimicrobial agents, compared to organic antimicrobial agents, have higher heat resistance (can withstand temperatures above 600℃), better safety, and more lasting antimicrobial effects. However, attention should also be paid to the complex reactions that may occur with certain additives in resins (such as sulfur-containing or halogen-containing stabilizers). These reactions can sometimes lead to discoloration of the product. Therefore, before practical application, it is usually recommended to conduct tests.Resistant to light and heat Perform verification by conducting color fastness tests.

In terms of regulationsThe Bactekiller series has actively responded to regulatory requirements in major global markets, including obtaining registrations or compliance statements with the US EPA, FDA (food contact), EU BPR (Biocidal Products Regulation), and China's GB9685. This provides significant support for its global application in a wide range of fields such as daily necessities, home appliances, building materials, and medical supplies.

In conclusion, integrating antibacterial functionality into plastic products, much like addressing odor issues, is a key aspect of innovation in material functionality.Choose thoroughly validated, regulatory compliant, and substrate-compatible antimicrobial agents, and combine them with rigorous testing to reliably develop high value-added plastic products that meet market demands for health and hygiene.。

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories