Recycled polyester products from mineral water bottles favored by burberry and armani

A shirt made of polyester fabric actually comes from recycled mineral water bottles. The garment features a rich variety of patterns and is comfortable to wear. This eco-friendly garment manufacturing technology has been widely adopted by Lutai Textile. "Well-known international brands like Burberry and Armani have established strategic partnerships with us. Burberry sources 90% of its shirt fabrics and trench coat linings from us. The market share of mid to high-end colored woven fabrics in export markets accounts for over 18% of the global market." Recently, the "Strengthening the Supply Chain to Benefit Enterprises · Quality Enjoyment in Shandong" media group visited the company’s processing plant to gain insights into the green technology products launched by Lutai Textile, such as recycled polyester and recycled cotton. This series of products achieves resource recycling and biodegradability, effectively protecting the environment while realizing zero waste and low carbon emissions, successfully addressing the environmental challenges faced by the textile industry and reducing energy consumption.

Walk into the production workshop.

In the factory area, the interview team observed that in the clean and bright workshop, dozens of small weaving machines were operating in an orderly manner. Each machine was equipped with a computer on its right side, displaying pattern designs and other data, while on the left side, automated "hands" were gradually forming different fabric samples with "every stitch and every thread." The entire cycle, including color yarn formulation, weaving process, and finishing inspection, could be completed in an average of five days.

Lutai Group's current main products are closely aligned with the industrial positioning of "technology, fashion, and green." They have launched new products such as BlueECO-Mist, comfortable wrinkle-free, and Printedyarn. According to reports, the BlueECO-Mist series uses a salt-free and alkali-free environmentally friendly dyeing process, resulting in less pollution discharge, and the fabric mimics the effects of denim and dyed cotton yarn; the comfortable wrinkle-free series imparts a softer feel to the fabric, offering higher wearing comfort; the Printedyarn series utilizes various cellulose fibers, such as hemp, Tencel, and modal, and can process various high, medium, and low count yarns, especially excelling in high count yarns. The entire production process is green and environmentally friendly, reducing water and chemical additives usage, achieving salt-free dyeing.

"In the process of setting carbon reduction targets in the textile industry, we have incorporated the added value of products into our considerations. At the same time, we strengthen the high-value utilization of old textiles, establish a comprehensive recycling, processing, and certification system for regenerated materials, and enhance standardized management within the industry to reduce environmental pollution," said Li Wenji, Deputy General Manager of Lutai Textile Co., Ltd. The company has received positive market feedback for its innovative research and development of self-cleaning fabrics, polar white fabrics, and cross-border knitting. In recent years, Lutai Textile has focused on tackling HCP green non-iron technology to create more wrinkle-resistant high-end fabrics. Additionally, leveraging the advantages of technological innovation across the entire industry chain, we have developed regenerated cotton, achieving zero waste and low carbon, effectively addressing the environmental challenges in the textile industry and saving energy and reducing consumption.

Recycling Technology Series

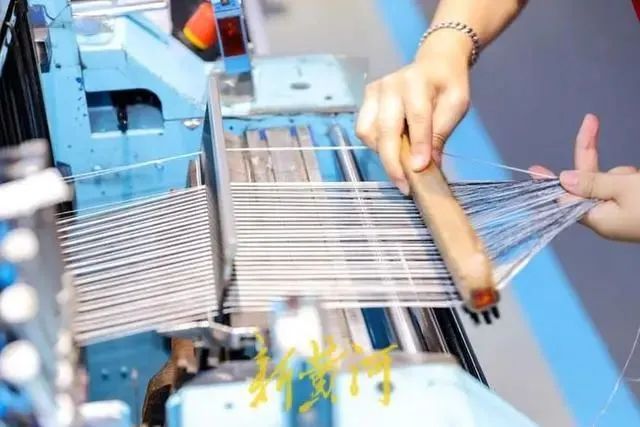

Taking recycled polyester as an example, its raw materials come from recycled mineral water bottles. The company compresses the sorted mineral water bottles into bricks, which are then transported to the rough processing workshop. In the rough processing enterprise, the bottles undergo cleaning, crushing, separation, and drying steps, transforming into white flakes. Next, the workshop workers treat the flakes through a series of techniques to produce yarn, which is then woven to create recycled fabric.

Nowadays, the series of products using recycling technology have obtained GRS (Global Recycled Standard) certification. The production process is environmentally friendly and can effectively protect soil and marine environments, saving nearly 80% of energy compared to conventional polyester production. Recycled cotton products utilize fabric scraps from recycling companies, achieving resource recycling and biodegradability, effectively protecting the environment. The four-way stretch knitted series features richer patterns and textures, combining comfort with a sense of fashion. "According to estimates, every ton of recycled cotton can save 1,600 tons of water, 1,800 kilowatt-hours of electricity, reduce arable land by about 10 acres, and decrease the use of fertilizers and pesticides by approximately 32 tons," Li Wenji introduced.

Thanks to breakthroughs in recycling technology, Lutai Textile's production and operational performance has consistently ranked among the top in the national textile industry. The company has been the top in China’s main business revenue for color woven fabrics for seventeen consecutive years, and it holds the largest market share in the mid-to-high-end color woven fabric market globally. Lutai has been recognized as a high-tech enterprise, a national industrial design center, a national enterprise technology center, and a CNAS national recognized laboratory, and is a "demonstration enterprise for champions in single-item manufacturing."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.

-

Which brand of AI TV is good? Samsung Vision AI interprets the new industry standard with its "technical advantage."