Research progress on surface modification of white carbon black and its applications

White carbon black is an amorphous nano SiO.2The material, characterized by high dispersibility, high porosity, good thermal stability, and electrical insulation, is widely used in industries such as catalysts, paper fillers, and reinforcing agents for rubber and plastics.

1 Overview of White Carbon Black

White carbon black is an amorphous white, non-toxic, amorphous powder material prepared on a large industrial scale. Its chemical name is colloidal silica, also known as hydrated amorphous silica (SiO).2·nH2O), due to its excellent chemical stability, high specific surface area, and electrical insulation properties, is widely used in the light and chemical industries. It has good thickening, thixotropic, and reinforcing properties, making it widely applied in the paint, paper, and rubber industries, thus providing a foundational new material for the development of related fields.

Surface modification of white carbon black

Surface modification of silica has been a research hotspot in recent years. The goal is to further enhance its performance and application value by altering the surface properties of silica. Due to the large number of hydroxyl groups on the surface of precipitated silica, it exhibits poor dispersion performance, is hydrophilic due to its tendency to adsorb water, and the aggregates have a tendency to coagulate, thereby affecting the application performance of silica products. To improve its application performance and efficacy, surface modification treatment is usually required before use to increase its dispersibility.

2.1 Modification Method

The modification methods of white carbon black are diverse, mainly including physical and chemical modification. Physical modification mainly refers to changing the surface properties of particles through physical adsorption, coating, mechanical stirring, etc.[3]Chemical modification involves introducing organic functional groups or altering surface charge properties to enable better integration of silica with the matrix. This mainly includes coupling agent modification, grafting modification, alcohol esterification modification, ionic liquid modification, polymer coating modification, and bio-based modification.

2.1.1 Physical Modification

The physical modification of silica mainly focuses on achieving modification by shielding or eliminating the silanol groups on its surface. This modification method mainly includes two major approaches: surface coating modification and high-temperature modification. Among them, the method of removing hydroxyl groups at high temperatures cannot effectively solve the dispersion issue. Surface coating primarily involves adsorption on the silica surface through hydrogen bonding or van der Waals forces between molecules, thereby reducing the density of surface silanol groups to improve dispersion.

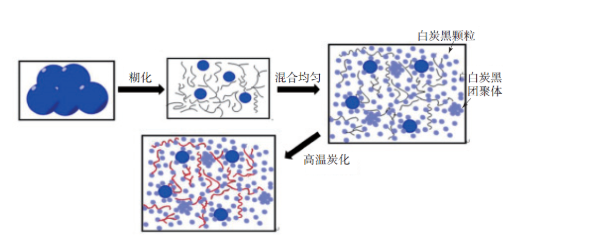

Zhang Yongjun and others used glucose as a modifier to coat the surface of silica through a carbonization method. The mechanism of carbon-coated silica is shown in Figure 1, and they studied the effect of glucose content on the comprehensive performance of rubber reinforced with silica. The results indicate that the dispersion of modified silica prepared by glucose carbon coating is significantly improved, and the comprehensive mechanical properties and processing performance of the rubber are enhanced.

Figure 1 Process Diagram of Carbon Coating on White Carbon Black

Additionally, the compression-heat method for modifying white carbon black is also a common physical modification technique, which involves mixing white carbon black with a modifier under high pressure and high temperature to improve its performance.

2.1.2 Coupling Agent Modification

Coupling agent modification can reduce the agglomeration of silica, offering advantages such as good modification effects and high controllability of the reaction. Commonly used coupling agents include silane coupling agents and borate ester coupling agents.

Silane coupling agent modification: Silane coupling agents (such as KH590, Si69, Si75) contain alkoxy groups and organic functional groups. The alkoxy groups hydrolyze to form silanols, which then react with the hydroxyl groups on the surface of silica to form covalent bonds. The organic functional groups crosslink with matrices such as rubber.

Yang Yinghao and others treated bio-based white carbon black with different modifiers and found that when using KH590 as the modifier, although the scorch time of the rubber compound is shortened due to the presence of mercapto groups, the mechanical properties, wear resistance, and dispersion performance of the rubber compound are better. Therefore, KH590 was chosen as the modifier, and the amount of modifier was determined. By varying the amount of KH590, it was found that when the amount of KH590 is 1%, the comprehensive performance of the white carbon black-reinforced rubber is optimal.

Boric acid ester coupling agent modification: The boric acid ester coupling agent combines with silica through both physical adsorption and chemical bonding.

Zhang Zhijian et al. prepared hydrophobic silica by modifying silica with borate ester coupling agent. The optimal modification process conditions were: the amount of borate ester coupling agent added was 10%, the activation temperature was 130°C, and the activation time was 30 minutes. Infrared and thermogravimetric analysis showed that the borate ester coupling agent was combined with silica in the forms of physical adsorption and chemical bonding. XRD analysis indicated that the addition of the coupling agent did not change the crystal state of silica. SEM analysis showed that the modified silica (CB10%) had good dispersibility in organic media, significantly improving the agglomeration phenomenon.

2.1.3 Grafting Modification

Surface grafting modification is a method to alter the surface properties of silica by introducing organic molecules with specific functional groups onto its surface. The basic steps involve activating the silica surface to generate some active groups, such as hydroxyl, acyl chloride, anhydride, etc. By reacting organic molecules with specific functional groups with the activated silica surface, new chemical bonds are formed, thereby firmly grafting the organic molecules onto the silica surface.

Liu Junyao[8]In further experiments, the modified STLF was compounded with the silane coupling agent TESPT to achieve surface modification of silica by preparing end-siloxane liquid fluororubber (STLF). The effect of different ratios of STLF/TESPT on the dispersibility of silica was investigated. A series of tests and characterizations were conducted, including vulcanization dynamic performance testing and scanning electron microscopy (SEM) analysis of vulcanized rubber. It was found that the addition of 2 parts end-siloxane liquid fluororubber and 4 parts TESPT to silica could effectively improve its dispersibility.

Polymer grafting for modification: Polymer grafting modification of silica refers to the introduction of polymer chains similar to the matrix on its surface, thereby increasing the compatibility between silica and the matrix. This can be divided into two methods: one is Grafting-to, which involves directly grafting end-functionalized polymers. The advantage of this method is its simplicity in operation and precise control over the type and amount of grafted polymers. However, due to steric hindrance effects, the grafting density might be limited, resulting in a lower grafting rate. The other method is Grafting-from, which involves introducing initiators or catalysts on the silica surface, allowing polymer chains to grow on the silica surface through in-situ polymerization.

Abdollahi et al. used aminopropyl-functionalized fumed silica as a raw material to synthesize modified silica nanoparticles through surface-initiated redox polymerization of styrene sulfonic acid and 2-acrylamido-2-methyl-1-propane sulfonic acid, and prepared anode composite membranes.

2.1.4 Alcohol Esterification Modification

The core of the alcohol esterification modification of white carbon black lies in utilizing alkyl alcohols to undergo an esterification reaction with the silanol groups on the surface of white carbon black. In this process, by controlling the reaction temperature, pressure, as well as the type and amount of the modifier, alkyl alcohols with specific chain lengths can be successfully grafted onto the surface of white carbon black. Generally, alkyl alcohols containing more than eight carbon atoms can impart higher organic characteristics to white carbon black. Additionally, the long carbon chains can cause a strong steric hindrance effect, resulting in white carbon black with improved modification effects.[11]。

Chen Ya and others used n-octanol to modify the surface of white carbon black and explored the effects of factors such as temperature, time, and dosage on the performance of white carbon black. They measured the lipophilicity value of the modified white carbon black to be around 30%, which can meet industrial needs.

Ion Liquid Modification

Ionic liquids (such as 1-butyl-3-methylimidazolium tetrafluoroborate and triphenyl octadecylphosphine iodide) are adsorbed on the surface of silica through hydrogen bonds and van der Waals forces, reducing hydrogen bonding between hydroxyl groups to inhibit agglomeration.[13]Ionic liquid modification can improve the dispersion of silica in rubber, accelerate the vulcanization rate, reduce the rolling resistance of rubber, and enhance wet skid resistance. At the same time, it can reduce the adsorption of vulcanizing agents by silica, maintaining the crosslink density of the matrix.

Sowińska-Baranowska et al.[14]By modifying silica with different specific surface areas using bromide ionic liquids and applying them in SSBR research, it was found that silica/rubber composites with larger specific surface areas exhibit lower crosslink density. The use of ionic liquids can also more significantly affect the optimum vulcanization time and crosslink density of the material. This is mainly because ionic liquids can adsorb onto the surface of silica, thereby reducing the adsorption of vulcanizing agents by silica.

2.1.6 Aggregated Coating Modification

The principle of coating modification involves covering the surface of silica with a layer of coating that has a different chemical composition, allowing the surface hydroxyl groups to be covered by polymers. This weakens the interaction force between the surface hydroxyl groups, thereby achieving the effect of reducing its dispersibility.

Yang Lei et al. used ultrasonic dispersion method to first perform surface graft modification on silica sol particles, then carried out microdroplet emulsion polymerization of silica sol particles with a small amount of octamethylcyclotetrasiloxane D4. Further infrared analysis, thermogravimetric analysis, and particle size analysis were conducted to characterize the samples. The ultrasonic dispersion method can achieve simple and efficient surface modification of silica sol particles.

2.1.7 Bio-based Modification

Modifying silica with naturally renewable resources (such as urushiol, cardanol, and rice husk extracts) aligns with the green and sustainable development concept. Urushiol contains phenolic hydroxyl groups that can react with the hydroxyl groups on the silica surface, and its alkyl chains can enhance hydrophobicity. Components in rice husk extracts, such as oleic acid and phospholipids, can modify silica through physical adsorption and chemical bonding, improving its compatibility with rubber and reducing the consumption of fossil resources and VOC emissions.

2.1.8 Other Modification Methods

Nanometer SiO2There are numerous modification methods, and in practical operations, it is not limited to using only one method to modify white carbon black. Often, multiple methods are used in combination, leveraging their respective advantages to achieve better results.

2.2 Modification Process

Silica modification processes include dry modification and wet modification. The dry method involves directly reacting finished silica with a modifier at high temperatures to achieve modification. Its greatest advantage is the simplicity of the process and fewer post-treatment procedures. However, it requires high equipment standards, has complex operating conditions, and incurs high preparation costs. The wet method involves surface modification of silica powder, generally requiring an organic solvent as a medium, which is costly and involves a complicated post-treatment process.

3. Applications of White Carbon Black

White carbon black is a high-performance industrial material widely used in many fields. Modified white carbon black has superior properties such as high specific surface area, high activity, and low density. Surface-modified white carbon black can enhance the mechanical properties, electrical conductivity, and wear resistance of composite materials.

3.1 Rubber Industry

Modified white carbon black is the core reinforcing filler for "green tires," significantly improving the mechanical and dynamic properties of rubber composites. In tire tread compounds, silane coupling agent-modified white carbon black can balance the "devil's triangle" of rolling resistance, wet skid resistance, and wear resistance. For example, KH590 modified acidic bio-based white carbon black (aggregate particle size 1-2μm) filled rubber achieves a tensile strength of 22.7 MPa, 300% modulus of 18.2 MPa, and a reduced loss factor at 60°C, thereby decreasing rolling resistance. High carbon alcohol modified white carbon black filled natural rubber shows improved wear resistance compared to unmodified samples, and its anti-aging properties are enhanced.

3.2 Coating and Plastics Industry

Hydrophobic modified white carbon black (such as borate ester and high-carbon alcohol modified products) can be used as a thickener and anti-settling agent in coatings, improving the thixotropy and stability of the coatings and reducing cracking of the coating layer. Adding modified white carbon black to plastics can enhance the rigidity, heat resistance, and impact resistance of the plastics, while improving dispersion uniformity to avoid performance fluctuations caused by agglomeration.

3.3 Environmental Protection and New Materials Field

The bio-based modified white carbon black prepared from industrial/agricultural waste such as steel slag and rice husk ash not only achieves the resource utilization of solid waste but can also be used in fields such as heavy metal soil remediation agents and dental composites. For example, the modified white carbon black prepared from steel slag achieves a silicon extraction rate of 70% under acidic conditions, and the product meets industrial quality requirements. The modified white carbon black from rice husk ash used in dental composites exhibits good biocompatibility and mechanical properties.

3.4 Other Fields

Incorporating modified hydrophobic fumed silica into powdered substances (such as dry powder extinguishing agents, tablets, and copier toner) improves the free flow and dispersion between powders, thereby preventing clumping and achieving uniform dispersion.

4 Summary

Silica is indispensable in various industries due to its unique nano-structure, but its surface hydroxyl groups lead to problems such as agglomeration and poor dispersion, limiting its applications. Surface modification is the core solution, with established systems including physical, chemical, and combined methods. Physical modification is easy to operate, while chemical modification (such as silane coupling agents and polymer grafting) is mainstream. New technologies like bio-based and ionic liquid modifications align with green concepts.

Modified white carbon black has significant value in the fields of rubber (supporting "green tires"), coatings and plastics, and environmental protection (promoting solid waste utilization). In the future, it will also expand into high-end new materials and other areas. Current research has entered a new phase, and it is necessary to address issues such as efficiency and cost balance to promote its industrial application and support the upgrading of the materials industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory