Salt Lake Shares to Form 80,000 Tons Lithium Salt Production Capacity This Year

“In the first half of 2025, the company’s lithium carbonate output was 20,000 tons, and sales reached 20,600 tons,” Salt Lake Co., Ltd. recently disclosed during an investor survey. The company’s 40,000-ton/year lithium salt project is progressing as planned, with the core adsorption lithium extraction unit successfully passing single-machine trial operation and intermediate acceptance, and qualified solution has already been produced.

The overall plan for the project is to start feeding and trial production by the end of September this year, at which time Salt Lake Co., Ltd. will achieve a production capacity of 80,000 tons per year of lithium salt.

In 2022, Salt Lake Co., Ltd. officially launched a 40,000 tons/year integrated basic lithium salt project. This project is a key construction project in Qinghai Province and has been included in the "Qinghai Action Plan for Building a World-Class Salt Lake Industry Base (2021-2035)." Initially, it planned to build production lines with an annual output of 20,000 tons of battery-grade lithium carbonate and 20,000 tons of lithium chloride.

In the early design phase of the project, the existing lithium extraction process of the subsidiary Lanke Lithium Industry was used as the foundation, adopting a combined process of "fixed-bed adsorption + membrane refining and concentration + MVR evaporation" to divert high-lithium solution for the production of lithium carbonate and lithium chloride products. During the advancement of the project, Salt Lake Corporation found that the original process had room for optimization and ultimately decided to make significant adjustments to the production plan.

On one hand, the product plan is uniformly adjusted to 40,000 tons per year of battery-grade lithium carbonate; on the other hand, the core adsorption process is upgraded by adopting a more advanced technology combination of "continuous ion moving bed adsorption + membrane refining concentration and boron removal + MVR evaporation."

"This technological innovation not only significantly improves the recovery rate of lithium resources and product purity, but also reduces the project's budget from 7.099 billion yuan to 6.083 billion yuan through equipment selection optimization and process streamlining," said Salt Lake Co.

For future development, Salt Lake Co., Ltd. has stated that it is implementing a "three-step" development strategy. The company plans to complete integration and optimization by 2025, establishing the prototype of a world-class salt lake industry. By 2030, it aims to achieve an annual production capacity of 200,000 tons of lithium salts and more than 30,000 tons of magnesium and magnesium-based materials. By 2035, the company intends to preliminarily build an industry cluster centered on salt lakes, encompassing the full lifecycle of the lithium battery industry, a green hydrogen recycling industry, a high-end magnesium-based materials industry, and a new energy storage industry, thereby becoming the largest and a world-class salt lake industry cluster in China.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

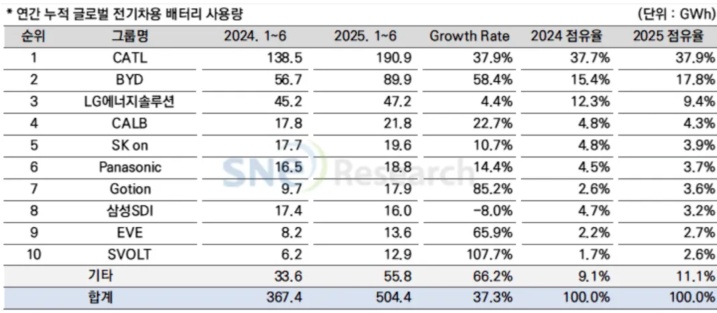

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%