Solvent Method Can Also Recycle HDPE, With Potential for Food-Grade Applications

According to relevant EU regulations, starting from 2030, packaging products must contain a minimum proportion of recycled materials. For PET, the food-grade recycling process is relatively mature, but in the field of HDPE, there is no widely recognized mature process within the EU food safety system.

Against this backdrop, the Austrian packaging and recycling plastics company Alpla Group has chosen to deploy a high-density polyethylene (HDPE) recycling project in the Netherlands, aiming to develop HDPE recycled material suitable for food contact packaging. The project adopts a solvent-based recycling process in its technical approach, which has sparked widespread attention in the industry regarding high-end recycling pathways for HDPE, seen as a proactive response to both regulatory and market pressures.

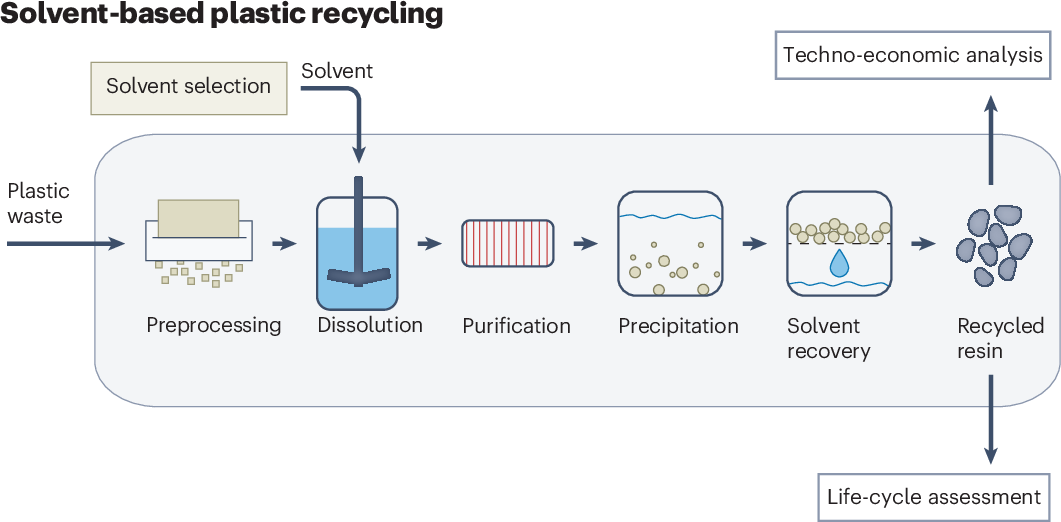

Solvent-based recycling is not a new concept, but its application in the HDPE field is still in the exploratory stage.

Previously, the solvent method was primarily used to improve the purity and performance of recycled PP, while HDPE faced greater commercialization challenges due to its high proportion of food contact applications and stringent regulatory requirements. Alpla's move signifies that the solvent method is transitioning from "technical validation" to "high-barrier application challenges."

— 1 —

Project Overview: Heerenveen Pilot Verification of Solvent-Based HDPE Recycling

Alpla is constructing a pilot plant in Heerenveen, Netherlands, and is collaborating with the local independent technology institute, the National Test Centre for Circular Plastics (NTCP), to systematically validate a patented solvent-based process.

Project duration: 4 years

Funding Agency: Netherlands Ministry of Climate Policy and Green Growth

Objective: Provide technical and data foundation for industrial scaling by around 2030.

Alpla has also established an independent recycling entity in the Netherlands to support the operation and subsequent expansion of the pilot project. In the Heerenveen pilot, Alpla is conducting intensive testing of the entire process, including target resin selective dissolution, impurity removal efficiency, solvent recovery stability, and the safety of regenerated materials.

Alpla's recycled plastics landscape: Globally, Alpla operates PET and HDPE recycling facilities at 14 locations, with an annual recycled plastic production capacity of approximately 400,000 tons. The products are primarily reused for packaging, particularly serving the fast-moving consumer goods (FMCG) market. The significance of the Netherlands project lies in extending from existing "large-scale recycling" to "high purity, food-contact grade applications," paving the way for recycled materials to enter the high-end packaging sector.

HDPE food-grade recycling is one of the most challenging yet potentially valuable technical issues in the field of plastic circularity.

HDPE is widely used for packaging dairy products, food seasonings, and drinking water, and it is extremely sensitive to odor and impurity migration. Although traditional mechanical recycling is mature, it struggles to meet regulatory requirements regarding food contact safety; on the other hand, chemical cracking is costly and complex. In contrast, solvent-based methods are considered one of the few "theoretically feasible" technological routes that achieve deep purification while maintaining the polymer molecular structure.

— 2 —

Regulatory Objective: Strive for EFSA Food Contact Certification

Alpla stated that one of the key objectives of the project is to obtain approval from the European Food Safety Authority (EFSA) for the solvent-based process. "So far, there is no certified process for recycled HDPE used in food contact packaging in the EU," pointed out Alpla's head of recycling technology. "If certified, this efficient cleaning and reprocessing technology could become a turning point for the industry."

The project team believes that the data accumulated during the construction and operation of the pilot plant will provide important evidence for determining whether the process is industrially feasible.

— 3 —

Industry Significance: Potential Breakthrough in HDPE Closed-Loop Recycling

HDPE is widely used in detergents, dairy products, household chemicals, and various daily chemical packaging, and is one of the important materials in the plastic packaging recycling system. However, to achieve a true "closed loop" in food-grade applications, not only is a well-established recycling system required, but also a certifiable high-purity regeneration process.

If Alpla and NTCP achieve breakthroughs in both technology and regulation in their pilot project in the Netherlands, it could have multiple impacts on the industry.

Provide brand owners with food-grade HDPE recycled material sources that meet regulatory requirements.

Establish a demonstration case of the solvent method process for recycling enterprises to promote the verification of more technical routes.

Provide policymakers and regulators with references based on actual operational data.

For the plastic recycling industry, which is currently at the intersection of "policy benefits" and "technical challenges," the progress of similar projects will directly impact the quality level and application boundaries of recycled plastics in the packaging market in the EU and globally in the coming years.

If the solvent method can be scaled and certified for HDPE, it will reshape the landscape of food-grade plastic recycling.

This not only has the potential to provide brand owners with a stable source of food-grade recycled materials but also opens up new technological and value opportunities for recycling companies, while offering the regulatory system decision-making references based on real industrial data.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage