Special engineering plastics leader net profit soars 1645.49%! today’s plastics market mostly dips, pc rises against trend by 500

1. Leading Special Engineering Plastics Company Soars by 1645.49%!

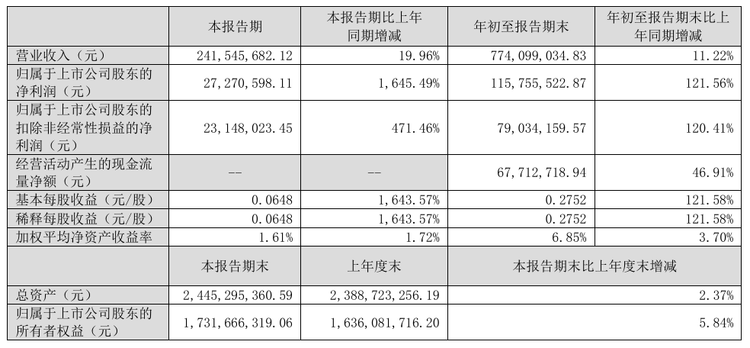

On the evening of October 22, Kaisheng New Materials announced its latest performance.

The revenue for the third quarter reached 242 million yuan, a year-on-year increase of 19.96%; the net profit attributable to the parent company reached 27.27 million yuan, a year-on-year surge of 1645.49%.

In the first three quarters, the operating revenue reached 774 million yuan, a year-on-year increase of 11.22%; the net profit attributable to the parent company was 116 million yuan, a year-on-year increase of 121.56%.

According to the announcement, the increase in performance is mainly attributed to the steady growth of main business revenue, the improvement of operating cash flow, and significant contributions from non-recurring gains, such as the receipt of 30 million yuan in technology compensation during the reporting period, representing a year-on-year increase of 4582.86%.

How much potential does the future hold?

Kaisheng New Materials is a high-tech enterprise primarily engaged in the research, production, and sales of fine chemical products and new polymer materials. It is a globally renowned producer of thionyl chloride and aramid polymer monomers, and is the third company in the world and the only one in China to achieve industrial production of high-performance material polyether ketone ketone (PEKK) with independent intellectual property rights.

It is reported that the company has established a comprehensive industrial chain structure, starting with basic chemical raw materials such as chlorine and sulfur, gradually extending to fine chemical intermediates like thionyl chloride, further extending to polymer monomers for high-purity aramid fibers such as isophthaloyl chloride/terephthaloyl chloride, and finally to high-performance polymer materials such as PEKK and its related functional products.

PEKK and PEEK, which have been very popular in the past two years, both belong to the polyaryletherketone family and share some common functional characteristics. They can be used interchangeably in specific fields. In the middle of this year, Kaisheng New Materials once achieved a "20CM" limit-up due to the related concept.

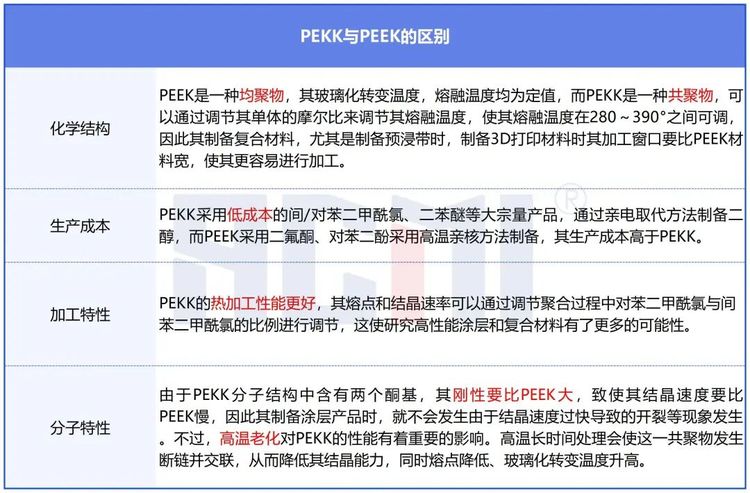

The main difference between these two materials is:

Additionally, as the first domestic company to break through PEKK technology and achieve mass production, Kaisheng New Materials has seen an increase in both production and shipment volume since it began operations. However, despite being a "small yet exquisite" material, the market still awaits a breakthrough.

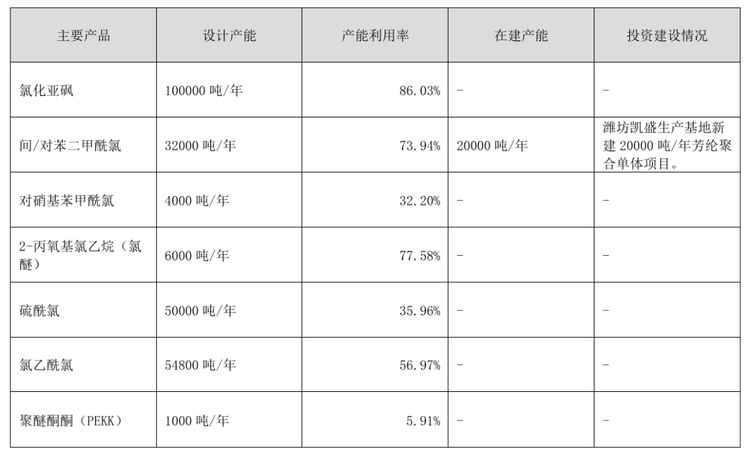

Over the past year, the capacity utilization rates of its main products are as follows:

At the beginning of last year, the company stated that its 1,000-ton/year polyetherketoneketone (PEKK) resin and molding application project had met the conditions for mass production, with its downstream currently focusing on the general profile and coating market. It is worth mentioning that this project underwent a change in 2022, with the production capacity being halved from 2,000 tons/year.

Special engineering plastics - Polyaryletherketone

Polyaryletherketone (PAEK) is a type of thermoplastic material characterized by an aromatic ring as its main chain structure, with ether bonds (—O—) and ketone groups (CO—) alternately connected. Due to its excellent high-temperature resistance, chemical stability, mechanical strength, and wear resistance, PAEK materials are widely used in high-tech fields such as aerospace, the automotive industry, electronics and electrical appliances, and medical devices.

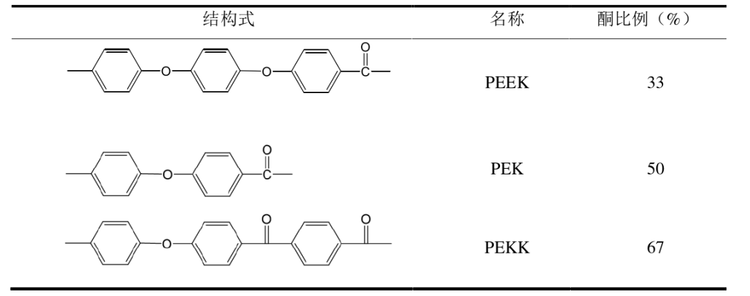

PAEK materials mainly include polyether ether ketone (PEEK), polyether ketone ketone (PEKK), and polyether ketone (PEK), and their characteristics and main downstream applications differ based on their molecular structure.

Types of Polyaryletherketone and Proportion of Ketone Bonds

The year 2025 is a crucial year for the breakthrough and development of China's specialty engineering plastics industry. The localization process of high-performance materials such as Polyimide (PI), Polyether Ether Ketone (PEEK), Polysulfone (PSF), High-Temperature Nylon (PA), Polyphenylene Sulfide (PPS), and Liquid Crystal Polymer (LCP) is accelerating. Their innovative applications in downstream fields such as aerospace, new energy vehicles, electronics and electrical, and medical devices are continuously deepening. The industry is encountering dual opportunities for technological upgrades and market expansion.

Section 2: Latest Plastic Prices

(The above is organized from Chemical New Materials and Dayi You Plastic.)

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?