Summary of Methods to Improve Plastic Rigidity and Toughness

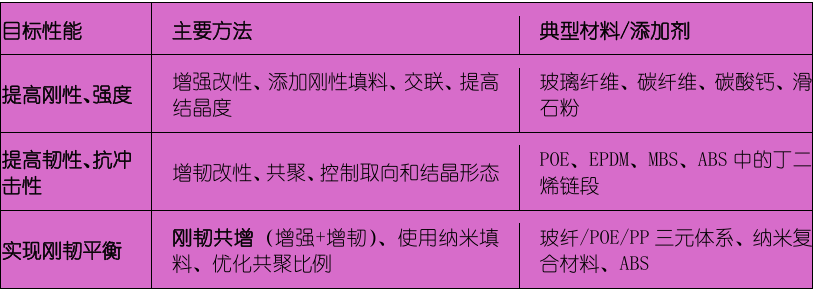

To make plastics more "rigid," it is essentially about balancing and optimizing their properties.Rigidity (deformation resistance ability)、Toughness (the ability to resist fracture, especially the ability to absorb energy) Impact resistance (the ability to withstand sudden impacts)The relationship between these three.

Typically, increasing rigidity may sacrifice some toughness, and vice versa. Therefore, the goal of "strength and toughness" is to significantly enhance toughness and impact resistance while maintaining sufficient rigidity through a series of technical means.

The following are the four main categories of methods to achieve this goal, progressing from molecular structure to macro composites:

Molecular structure design (chemical methods)

This is a fundamental modification made during the polymer synthesis stage.

1. Co-gather:

Principle:Polymerizing two or more different monomers together to incorporate segments with different properties into the molecular chain.

ABS plastic is a typical copolymer, composed of acrylonitrile, butadiene, and styrene. Acrylonitrile provides rigidity and heat resistance, butadiene offers toughness and impact resistance, and styrene contributes to processability and gloss. By adjusting the proportions of these three components, the rigidity and toughness of the final product can be precisely controlled.

Cross-linking:

Principle:Chemical bonds (bridges) are formed between linear polymer chains, making them into a three-dimensional network structure.

Effect:Significantly increases strength, rigidity, heat resistance, and creep resistance. However, excessive cross-linking can cause the material to become brittle.

Application:Cross-linked polyethylene is used for pipes and wire and cable, and its impact resistance and resistance to environmental stress cracking are far superior to those of ordinary PE.

Blending and alloying (physical methods)

This is the most commonly used and flexible modification method, which involves physically mixing different types of plastics or elastomers together.

Toughening modification:

Principle:In rigid plastic matrices (such as PP, PA, PBT, PC), small rubber or elastomer particles (such as EPDM, POE, SBS, MBS) are incorporated.

Mechanism of action:When the material is subjected to impact, these small elastic particles act as "stress concentration points," which can induce the matrix to generate a large number of silver streaks and shear bands, thereby absorbing a significant amount of impact energy and preventing crack propagation.

Application:Almost all engineering plastics (such as toughened nylon and toughened polycarbonate) use this method to improve impact resistance. Car bumpers are a typical example of toughened polypropylene material.

2. Enhancement and modification:

Principle:Adding fibrous or flaky reinforcing materials to a plastic matrix, the most typical isFiberglass Carbon fiber。

Mechanism of action:Fiber, as a carrier, greatly enhances the rigidity and strength of materials. It acts like the steel reinforcement in reinforced concrete, effectively resisting deformation and tension.

Effect:Rigidity, strength, and heat resistance are greatly improved, but this usually leads to complex changes in impact resistance (usually the notched impact strength decreases, but the unnotched impact may increase), and the material loses toughness, becoming "hard and brittle."

3. Mutual Reinforcement of Firmness and Flexibility:

Principle: Enhancer(such as fiberglass) andToughening agent(Add elastomers) simultaneously into the same plastic matrix to achieve "rigid-tough balance."

Challenges and Solutions:This requires precise formulations and process control, as the toughening agent may affect the bonding strength between the glass fibers and the matrix.CompatibilizerTo improve the interfacial bonding between the components.

Application:High-end tool housings, automotive engine peripheral components, sports equipment.

Add modifier and filler

On the basis of blending, add other functional fillers.

1. Rigid filler:

Category:Calcium carbonate, talc powder, barium sulfate, and wollastonite.

Effect:Mainly improve rigidity and strength, reduce costs, but the improvement in toughness is limited; excessive addition usually lowers toughness.

2. Nanofillers:

Category:Nanomontmorillonite, nanocalcium carbonate, graphene, carbon nanotubes, etc.

Principle:Due to the large specific surface area and special interfacial effects of nanomaterials, adding a small amount (usually 1-5%) can significantly improve the rigidity, strength, and toughness of the material simultaneously, achieving "nano-enhanced toughening."

Advantages:This is the forefront of current materials research, capable of achieving a leap in performance, but with high technical difficulty and cost.

Process Control

The same formula, different processing techniques can significantly affect the performance of the final product.

1. Orientation:

Principle:During the processing (such as injection molding, extrusion, stretching), polymer chains or fibrous fillers will align along the flow or stretching direction, resulting in an "oriented" structure.

Effect:The strength, stiffness, and impact resistance along the orientation direction will be significantly improved, while the performance in the vertical direction will be weakened. This results in the anisotropy of the material.

2. Control of Crystallinity and Crystal Form:

Principle:For crystalline plastics such as polypropylene and nylon, the crystallinity and crystal morphology can be altered by controlling the cooling rate and adding nucleating agents.

Effect:Higher crystallinity usually increases rigidity, strength, and heat resistance, but may reduce toughness. However, forming a specific crystal form (such as the β crystal form of PP) can improve toughness while maintaining rigidity.

3. Annealing/Heat Treatment:

Principle:Heat the molded plastic products at a specific temperature for a period of time, then cool them slowly.

Effect:Eliminate internal stress and improve crystal structure, thereby enhancing dimensional stability, strength, and toughness.

Summary and Examples

A typical case of "rigid" plastic: automotive bumpers.

✔Matrix:Polypropylene, low cost, good processability.

Toughening agent:EPDM or POE elastomers provide low-temperature impact resistance, ensuring they do not easily shatter upon collision.

Enhancer:Talc powder or short glass fibers provide sufficient rigidity to support the appearance and installation components.

Compatibilizer:Ensure that all components are closely integrated to leverage synergistic effects.

Through such meticulous "material formulation design" and "process control," we have ultimately obtained a plastic component that is both lightweight and meets safety requirements, embodying both rigidity and strength.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?