Syensqo and Bell Join Forces to Accelerate the Industrialization of Aerospace Composites

Advanced materials supplier Syensqo has partnered with aerospace and defense company Bell Textron to accelerate the industrialization process of composite materials. Bell is an early adopter of Syensqo's patented Double Diaphragm Forming (DDF) manufacturing process, which utilizes Syensqo's fast-curing aerospace prepreg Cycom EP 2750. This material is designed based on a toughened epoxy resin system specifically for high-speed, cost-effective composite manufacturing, suitable for compression molding of medium to small parts.

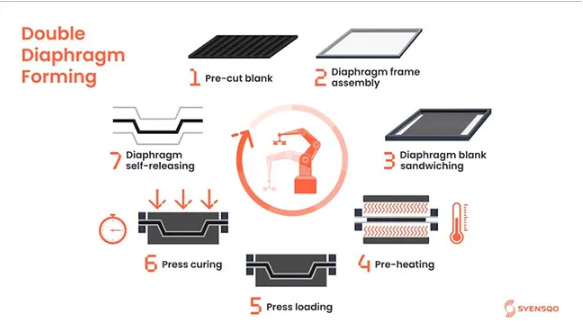

The Double Diaphragm Forming (DDF) method integrates the automation of dry fiber preforming, prepreg preforming, or compression molding into a single-step process. Image provided by Sika.

Single-step process

The Double Diaphragm Forming (DDF) method integrates the automation of dry fiber preforming, prepreg preforming, or compression molding into a single-step process, reducing the cycle time for part manufacturing. This technology also lowers labor costs and processing time because the two layers of diaphragms eliminate the need for tool preparation and cooling steps during the forming process. Furthermore, the diaphragm itself can serve as a protective layer for painting and bonding operations.

Accelerated Certification and Commercialization

Bell quickly completed the certification and industrial application of Double Diaphragm Forming (DDF) technology, achieving high-speed production of aerospace composite material parts. The application of this new process has brought numerous significant benefits, such as reducing operating costs, while also having a positive environmental impact by reducing waste, energy consumption, and greenhouse gas emissions. Additionally, the DDF technology eliminates the need for autoclave curing for small to medium-sized parts, making it applicable for the production of large parts. This technology supports the production of up to 50,000 structural components per year on a single production line.

Thirty years of partnership.

"For over thirty years, the collaboration between Hexcel and Bell has continuously brought innovative solutions, benefiting the composite materials industry," said Marc Doyle, Executive Vice President of Hexcel's Composite Materials business. "Hexcel's customer support model is based on a core belief: design, materials, and manufacturing are interconnected and are key to driving the widespread adoption of composite materials. Our team structure is designed to support this model, and collaboration with customers is the foundation for achieving a higher degree of industrialization in the composite materials industry."

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories