Ten years of research! plant/mushroom extracts used to create high-barrier bio-based films

Seeking viable sustainable flexible packaging made from renewable materials to replace traditional plastics, with the core challenge being performance barriers.

To achieve widespread application, researchers must design films that can effectively block moisture and oxygen. These barrier properties are crucial for protecting food, pharmaceuticals, and precision electronics.

Researchers at the Georgia Institute of Technology have developed a bio-based film derived from natural ingredients found in plants, mushrooms, and food waste, with moisture and oxygen barrier properties comparable to traditional plastics. The research findings were recently published in the journal ACS Applied Polymer Materials.

"We use materials that are abundant in nature and can biodegrade to make packaging, avoiding pollution in the environment for hundreds or even thousands of years," said Carson Meredith, a professor at the Georgia Institute of Technology's School of Chemical and Biomolecular Engineering and executive director of the Renewable Bioproducts Institute. "Our films are made from biodegradable components and perform on par with or even better than traditional plastics in keeping food fresh and safe."

A sword polished for ten years.

Meredith's research team spent over a decade dedicated to developing environmentally friendly oxygen and moisture barrier materials for packaging. Although early research based on biopolymers showed potential, high humidity environments still compromised their barrier performance.

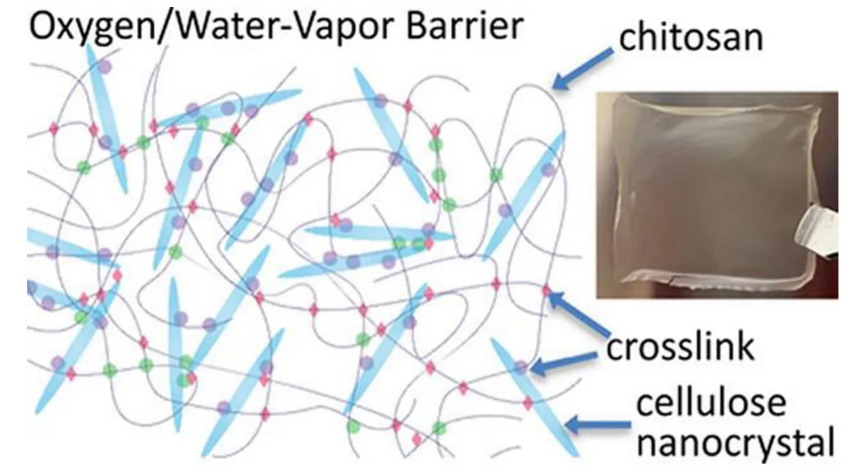

Meredith and her collaborators found a solution: using a mixture of various natural ingredients, including cellulose that gives structure to plants, chitosan derived from shellfish waste or mushrooms, and citric acid from citrus fruits.

Crosslinking is key.

"By cross-linking these materials and applying heat treatment, we have created a film that can significantly reduce the permeability of moisture and oxygen, even in the high temperature and humidity environment simulated for tropical regions," said Lu Yang, the first author of the study and a former postdoctoral researcher at the Georgia Institute of Technology's School of Chemical and Biomolecular Engineering.

The barrier technology developed by researchers consists of three core components: carbohydrate polymers that provide structural support, plasticizers that maintain flexibility, and hydrophobic additives that resist moisture. When these components are made into a film, they self-organize at the molecular level to form a dense and orderly structure, preventing swelling or softening in high humidity environments.

Performance surpasses PET and EVOH.

Even in an environment with 80% relative humidity, the film exhibits extremely low oxygen permeability and water vapor transmission rates, with performance reaching or even exceeding that of commonly used plastics such as polyethylene terephthalate (PET) and ethylene-vinyl alcohol (EVOH).

"Our approach not only achieves the renewability of barrier materials but also ensures excellent mechanical strength, providing a promising alternative to traditional plastics in the packaging field," said Natalie St. John, professor and dean of the School of Materials Science and Engineering at Georgia Tech, who also serves as a professor in the School of Chemical and Biomolecular Engineering.

The technology has currently applied for a patent.

Financial Support

This research was supported by Mars, the Renewable Bioproducts Institute at Georgia Institute of Technology, and the Department of Defense through the National Defense Science and Engineering Graduate Fellowship program. Research co-author Eric Klingenberg is an employee of the packaging food manufacturer Mars.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory