WACKER to Launch High Consistency Silicone Rubber for Composite Insulators at K 2025

WACKER will introduce a new type of high-consistency silicone rubber for the production of extruded silicone housing composite insulators at the next K 2025 International Plastics and Rubber Trade Fair.

The new product is available in the form of a 2K additive curing system, suitable for extrusion manufacturing processes, especially screw extrusion. Compared with other production methods, this makes it easier and more cost-effective to manufacture large insulators with variable diameters. K 2025 will be held in Düsseldorf, Germany, from October 8 to 15.

Manufacture high-precision large insulators at a relatively low cost.

Composite hollow insulators belong to the category of composite insulators. They basically consist of a hollow non-conductive tube with an annular insulating shell on the outside, made of non-conductive materials. Hollow insulators are used in electrical equipment such as bushings, instrument transformers, circuit breakers, or arresters. Their size can be quite large, especially in high voltage applications. Diameters exceeding one meter and lengths over ten meters are not uncommon. However, due to their relatively light weight, composite hollow insulators are easier to install compared to traditional ceramic insulators. The weight reduction can add up to as much as 80%.

At this year’s international plastics and rubber trade fair, chemical company WACKER will showcase a new high-consistency silicone rubber specifically developed for the production of extruded silicone housings for composite insulators. This includes particularly large hollow insulators. POWERSIL® 1900 A/B can be used to manufacture such components using the so-called helical extrusion process.

Here, the silicone elastomer is extruded onto a continuously rotating insulating tube, ensuring a thoroughly uniform application of the complex outer shed. Due to this process, manufacturers can even produce high-precision large insulators at a relatively low cost. In addition, conical shapes can also be produced—something that traditional injection molding techniques usually cannot achieve.

WACKER offers POWERSIL® 1900 A/B, a ready-to-use 2K high-viscosity silicone rubber. This product cures by addition curing to form an electrically insulating silicone elastomer with excellent tracking resistance, erosion resistance, and arc resistance. No by-products are released during curing. Insulating housings with sheds have water-repellent and anti-pollution surfaces. Unlike porcelain or glass, they maintain excellent dielectric properties even during continuous operation or exposure to rain and high humidity in salty or dusty conditions. Rainwater and dirty water simply drip off the water-repellent silicone housing. In most cases, this also eliminates the need for costly cleaning of composite insulators.

As an elastomer, POWERSIL® 1900 A/B possesses excellent mechanical properties. It features UV resistance and, thanks to its elasticity, can withstand various weather conditions, earthquakes, and acts of vandalism better than other materials. Therefore, silicone elastomers can also enhance grid resilience and ensure a safe power supply.

Organic silicon in power engineering

For decades, silicone elastomers have been a conventional feature in high-voltage engineering. As a high-performance insulating material, they possess numerous characteristics unmatched by other materials. In addition to high tracking resistance, erosion resistance, and arc resistance, silicones also have exceptional weather resistance and UV radiation resistance. They can withstand high temperatures, cold, and extreme temperature fluctuations.

The waterproof surface of cured elastomers is another typical characteristic of silicone elastomers: they can maintain their waterproof properties even when contaminated. This property, known in technical terms as "hydrophobicity" and "hydrophobicity transfer," prevents the formation of conductive layers of water, dirt, and salts, which could otherwise lead to electrical failures of insulators due to flashover. Therefore, it is no surprise that silicone elastomers are now used in almost all areas of power transmission and generation.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

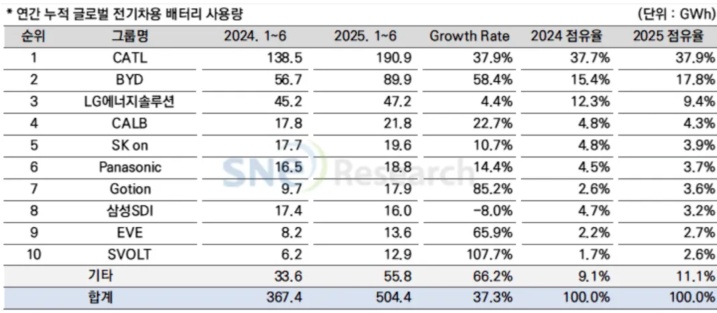

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%