What Is YHIII Comparing When the Manufacturing Industry Is Anxious About Costs?

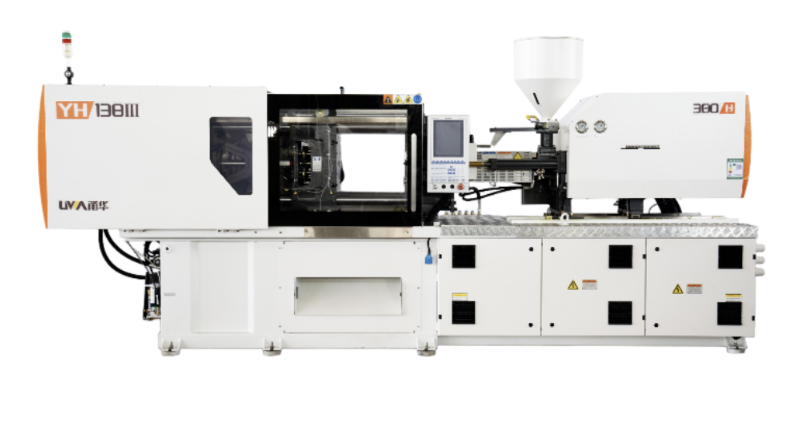

In the face of rising costs and increasingly fierce competition, how injection molding companies can ensure product quality while achieving cost reduction and efficiency has become a critical issue for survival and development. The Yonghua YHIII electric pre-plastic series injection molding machines have emerged in response, offering industry clients a practical solution with precise technological innovation and quantifiable economic benefits.

01

Energy saving 35%: a new benchmark for cost restructuring.

The core technology of electric pre-plasticization achieves a significant reduction in energy consumption.Actual energy savings of 15%-35%.The synchronized melt function further optimizes energy consumption performance, and the all-electric pre-plasticizing technology completely eliminates the risk of oil pollution while significantly reducing noise. This provides strong support for home appliance companies to build clean factories and achieve sustainable development, helping enterprises realize green and low-carbon manufacturing. Truly achieve "energy saving is profit."

02

Efficiency increased by 40%: breaking new ground in production capacity.

High-mixing screw designPlasticizing efficiency increased by 15%-40%.Combining with the synchronous hot melt function.The molding cycle is shortened by more than 20%.Significant improvement in production efficiency helps customers respond quickly to market demands and maximize capacity.

03

Accuracy 0.3%: New Standard for Quality Control

Low inertia injection system coordinated with intelligent algorithms.Achieve injection accuracy ≤ 0.3%, clamping force repeatability ≤ 0.5%.Effectively avoiding defects such as flow marks and shrinkage, significantly enhancing product consistency and laying a solid foundation for high-quality manufacturing for customers.

04

Maintenance-free design: New assurance for stable operation

To completely eliminate the risk of oil leakage, choose high-safety sealing components to prevent oil leakage from the source, ensure consistent factory production efficiency, and achieve stability.Truly maintenance-freeThe equipment utilization rate has significantly improved, and unplanned downtime has greatly reduced, providing customers with continuous and reliable production assurance.

Choosing Yonghua means that for manufacturing enterprises, it not only signifies the iteration and upgrade of production equipment but also introduces a strategic partner committed to sustainable development. Through the deep integration of innovative technologies, both parties aim to jointly promote the reconstruction of industrial value, striving to usher in a new era of manufacturing that is more efficient, lean, and green.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?