Xiangsheng Technology Secures Multi-Million Yuan Funding to Industrialize Bio-Based Materials via Microfluidic Technology

According to MEMS Consulting, Xiang Sheng Technology, an industrialization enterprise focusing on the microfluidic intelligent manufacturing of bio-based and high-performance materials, recently announced the completion of two consecutive rounds of Angel+ funding, totaling tens of millions of yuan. This round of financing was jointly led by industry CVC Meili Jingjie Capital, IDG Capital, and Nachuan Capital, with follow-on investments from institutions such as Inno Angel Fund, Suzhou Venture Capital, Suzhou Angel Mother Fund, and Suzhou High-tech Venture Capital Angel Fund. The funds will be primarily used for the construction of an AI catalysis technology platform, product R&D, production line expansion, and smart factory construction.

Founded in January 2024, "Xiangsheng Technology" relies on scientific research platforms such as the Research Institute of Tsinghua University in Shenzhen and the National Key Laboratory of Nanjing Tech University. The company is committed to promoting the industrialization of bio-based materials through microfluidic technology. The founder, Yu Chao, returned to China in 2020 as a Jiangsu Specially-Appointed Professor, leading a team to conduct engineering research on AI nanocatalysis and multiphase microreactors. Team members come from prestigious domestic and international universities, including Brown University, the University of Cambridge, and Nanjing University of Science and Technology, possessing strong interdisciplinary technical backgrounds.

The company's core product, bio-based furan material FDCA (2,5-furandicarboxylic acid) and its polyester PEF, are disrupting the market landscape of traditional petroleum-based material PET. Unlike PET's raw material PTA, FDCA can be extracted from biomass such as corn and straw, possesses biodegradable properties, and exhibits excellent performance in barrier properties and mechanical strength. For example, milk packaging made from FDCA polymer materials can double the shelf life and is also suitable for the transportation and storage of carbonated liquids such as beer.

Recognized by the U.S. Department of Energy as one of the 12 most promising bio-based platform chemicals, FDCA can be chemically modified to derive high-performance materials such as polyamides and epoxy resins. However, its industrialization faces challenges such as high costs and processing difficulties. "Xiangsheng Technology" has reduced production costs by more than 40% through its self-developed multiphase microfluidic matrix reaction platform, and has achieved the landing of a hundred-ton-level production line, with plans to upgrade to a thousand-ton-level flexible production line next year.

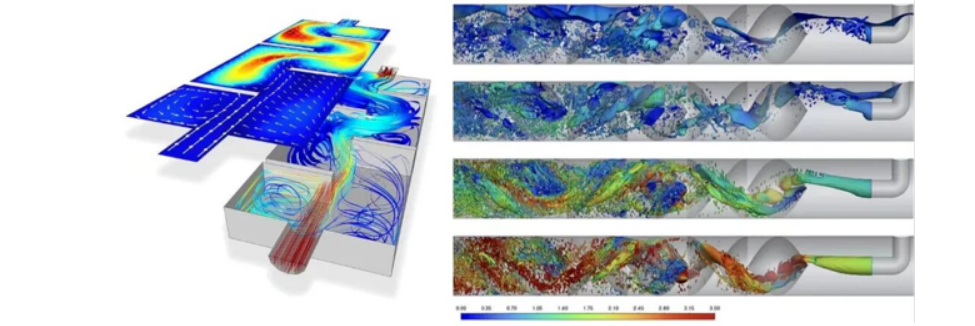

This platform comprises two core modules: the AI Nanocatalyst Module, which constructs catalyst prediction models through microfluidic high-throughput experiments, precisely controlling reaction conditions at the nanoscale; and the Fluid Simulation Calculation Module, which optimizes heat and mass transfer to achieve one-step FDCA production with a 30% yield increase. This modular design enables "building block" style expansion of the production line, allowing for rapid adaptation to different reaction systems.

In terms of its business model, "Xiangsheng Technology" adopts a "1+N" strategy: "1" focuses on bio-based new materials, implementing an international expansion strategy across four major areas including functional polyester films and nano-coatings, and has completed mass production tests with multiple overseas brand owners; "N" provides CRDMO services in fields such as electronic chemicals and organic optoelectronic materials based on its technology platform, primarily targeting import substitution products. The company's order scale is expected to reach tens of millions of yuan by 2025, with revenue equally split between the two business lines, and a projected profit growth of 40-50% over the next 3-4 years.

Currently, the company's technology has been applied in areas such as functional polyester films and nano-coatings, and it has established supply chain partnerships with multiple Fortune 500 companies. The next step involves building a thousand-ton-scale intelligent micro-factory to accelerate the mass production of high-performance materials. Its Domino Flow Chemistry Model (DFCM) achieves a seamless transition from laboratory to thousand-ton production through a "trigger-transfer-amplify" mechanism, providing intelligent solutions for the fine chemical industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories