Zhenxiong K Exhibition 2025 Successfully Concludes: Building a New Future for AI Injection Molding, Smart Manufacturing Ecosystem Draws Global Attention

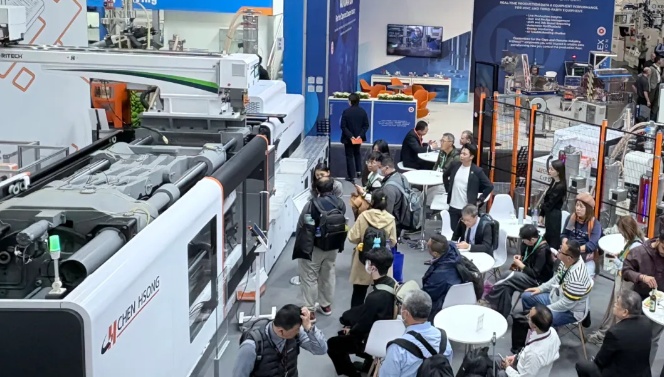

On October 15, 2025, local time in Düsseldorf, Germany—K 2025, the global rubber and plastics event, concluded successfully amidst enthusiastic responses. Zhenxiong, themed "AI Era: A New Journey in Plastics,"Created a "Future Injection Molding Experience" feast that deeply integrates intelligent technology and industrial ecology....become the focal point of attention during the exhibition.

Smart ecology, leading the future

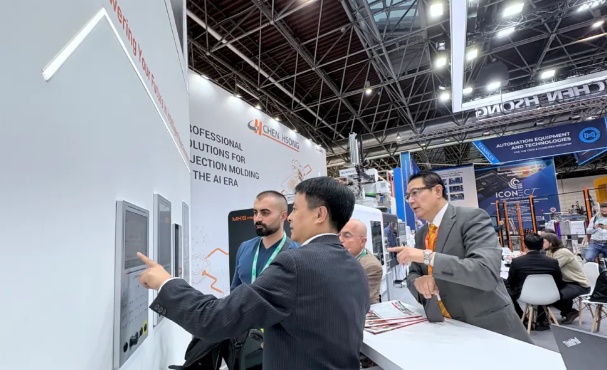

「When each injection molding machine has a "brain" that can think」

During the exhibition, Chen Hsong officially launchedChen Hsong Intelligent Industry iChen™ Smart Family, featuring Chen Hsong Cloud, Smart Factory, and Smart Injection Molding Helper.The architecture of the Trinity has constructed a system.Integration, Low Threshold, High EfficiencyAn intelligent manufacturing ecosystem. Both small and medium-sized enterprises and large manufacturing groups can easily achieve intelligent upgrades through this system, significantly enhancing production efficiency and product quality.

· iChen™ Smart Factory:Focusing on factory full-line design, integrate the entire production line from front-end to back-end, and achieve turnkey projects for the whole plant.

· iChen™ Cloud:The Chen Hsong Intelligent Manufacturing Operations Management Platform enables digital control of the entire production cycle and provides real-time operational insights.

· iChen™ AI Molder:Optimize forming parameters precisely to eliminate product defects and improve production yield.

Empower thousands of industries.

「Live Demonstration of Three Major Innovative Solutions」

· Household Supplies Solutions

At this exhibition,SPARK EH Three-Stage Multi-Color Electric Injection Molding MachineThrough a live demonstration of the integrated molding of multi-material products using a portable magnifying glass, its "multi-functionality in one machine" was fully showcased, relying on...Flexible combination technology of multiple shooting platforms enables integrated molding of multiple materials.Completely bid farewell to the traditional multi-machine division of labor model, significantly improving production efficiency and product yield, while also being widely applicable to various production needs in industries such as healthcare, optics, toys, and automotive.

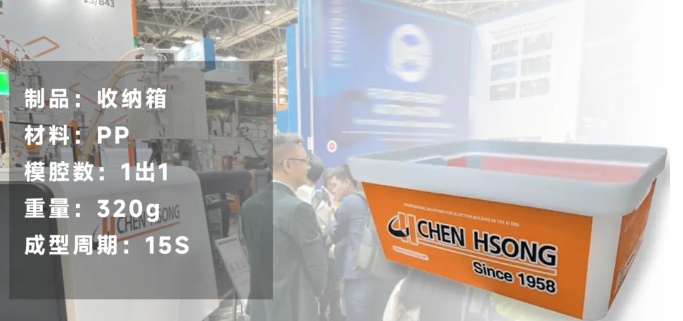

· Home Goods Solutions

MK6 PRO Precision Servo Injection Molding MachineAs the core model with a 98% reorder rate for Zhenxiong, it attracted much attention at this K Show.Upgrade the electric glue melting device.Working with needle valve molds or closed nozzles to achieve synchronized melting, precisely controlling the melting process, significantly enhances product accuracy and production efficiency. The repeatability accuracy of the product can reach ≤1g, effectively ensuring the stability and consistency of the weight of products such as storage boxes, and meeting European green production requirements.

Industrial Supplies Solutions

Chen Hsong's new product debut at this exhibition—the NTP-DMZ III backpack-type multi-material injection molding machine, features a European-style precision turntable and servo motor drive system, achieving an ultra-high positioning accuracy of ±0.005°, meeting the stringent quality requirements of the European market.Modular design and backpack launch mechanism support flexible switching between single and dual colors, enabling simultaneous multi-color/multi-material one-shot molding technology.Efficiently complete the integrated molding of complex structures such as "handle + multi-partition box," ensuring consistent quality while significantly enhancing production efficiency and flexible manufacturing capabilities.

Technological and Market Win-Win

「Media Focus, Frequent Signing, Technical Demonstration, and Intelligent Exchange」

The K exhibition may have concluded, but Chen Hsong and its global partners are just beginning a new journey towards creating an intelligent injection molding future.Thank you sincerely to every partner who visited booth B43 in Hall 13. Your attention and trust are the inexhaustible driving force for Chen Hsong's continuous innovation.

In the future, Chen Hsong will continue to focus on the "smart injection molding ecosystem," closely partnering with global customers and partners to jointly advance the manufacturing industry towards greater efficiency, intelligence, and sustainability.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?