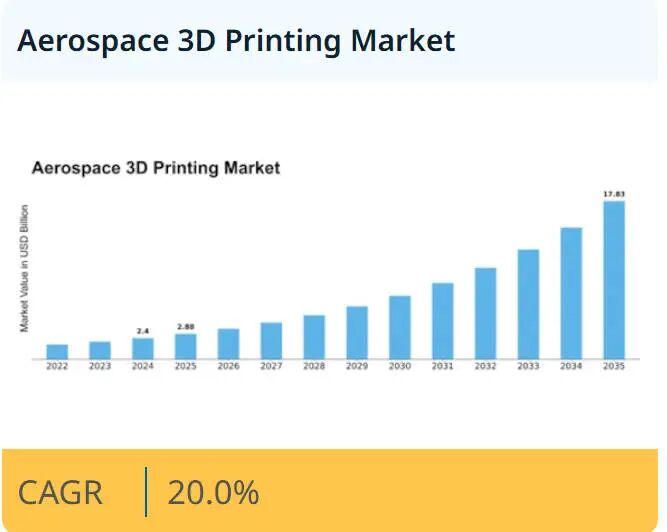

Aerospace 3D Printing Market Accelerates Development, Expected to Exceed $17.8 Billion by 2035

According to Market Research Future (MRFR), the global aerospace 3D printing market is expected to reach approximately $2.4 billion by 2024.The market is expected to steadily rise from $2.88 billion in 2025 to $17.83 billion in 2035, with a compound annual growth rate (CAGR) of 20.0% between 2025 and 2035.3D printing is profoundly changing the production methods of aircraft and spacecraft components. It can create complex geometric structures, significantly reduce material waste, and notably shorten the manufacturing cycle.

Core Growth Drivers

The industry's urgent demand for lightweight aircraft is the main driver. Lightweight components can improve fuel efficiency and reduce carbon emissions. Meanwhile, aviation manufacturers face dual pressures of cost control and accelerated delivery, prompting them to adopt 3D printing technology more quickly. This technology can produce highly customized, structurally complex parts with extremely low waste rates, greatly aligning with aerospace engineering's requirements for performance and efficiency. The rapid prototyping capability also accelerates design validation and iteration. Additionally, the continuous growth in orders for new-generation aircraft and spacecraft, along with the expansion of commercial fleets, further drives market demand. Advancements in printable materials such as high-performance polymers and metal alloys also enable 3D printed parts to meet stringent aviation standards in terms of strength and reliability.

Market segmentation pattern

The market is divided into metal-based, polymer-based, and ceramic-based 3D printing by material type. Among them,Metal-based components dominate and are widely used in engines and load-bearing structural parts.;The application of polymer-based materials is increasing in cabin interiors and lightweight non-load-bearing components, while ceramic-based materials are gradually entering high-temperature environment scenarios.

• Based on usage, it includes prototyping, tooling and fixtures, and functional parts manufacturing. Prototyping remains the fundamental application, but functional parts manufacturing is rapidly growing, with more and more.Certified 3D printed parts have been used in commercial and military aircraft.。

In terms of technology,Stereolithography (SLA) occupies the largest market share.SLA can produce high-precision parts, making it the preferred choice for manufacturing complex prototypes and components in aerospace applications. Meanwhile, Selective Laser Sintering (SLS), with its ability to utilize a variety of materials and produce durable parts crucial to aerospace functions, is rapidly becoming the fastest-growing technology.

Future Key Opportunities

As more critical components receive airworthiness certification, 3D printing will shift from a supporting role to a core manufacturing process. Countries are increasing investments in space programs, creating new demand for high-performance printed components. The integration of artificial intelligence and digital twin technology with additive manufacturing is expected to optimize the efficiency of the entire process. The introduction of 3D printing in repair, maintenance, and overhaul opens up new business paths. The continuous advancement in new material development will further expand the boundaries of application.

North America is currently leading the global market, relying on a strong aerospace manufacturing ecosystem, advanced technology adoption rate, and continued investment in the defense and aerospace sectors.

Europe follows closely, benefiting from aircraft mass production, sustainable development strategies, and emphasis on lightweight manufacturing. Strict environmental regulations and fuel efficiency requirements also promote the widespread adoption of 3D printing.

The Asia-Pacific region will become the fastest-growing market, driven by the expansion of commercial aviation fleets, increased defense spending, and the rapid development of domestic aviation manufacturing capabilities.

Industry Trend Observation

The current prominent trend is moving from prototype verification to mass production certification of parts. The application of metal 3D printing in engines and main structural components is becoming increasingly mature. An integrated design, simulation, and printing digital manufacturing system is taking shape. The industry is also focusing on sustainable manufacturing by reducing waste and energy consumption. Breakthroughs in multi-material printing and large component printing technology are expanding the possibilities of 3D printing in aerospace.

Market participants are highly focused on technological innovation and large-scale production capabilities.The company establishes a differentiated advantage through its proprietary printing processes, expertise in materials, and ability to meet aviation quality standards. Strategic cooperation with OEMs and research institutions is key to strengthening its market position.Continuous investment in research and development is crucial for improving printing precision, material performance, and certification readiness. As 3D printing becomes more deeply integrated into the aerospace manufacturing system, competition will become increasingly intense.

Aerospace 3D printing is transforming from an "auxiliary tool" to one of the "core manufacturing methods." Driven by lightweighting, cost reduction and efficiency improvement, and digital transformation.This market is expected to maintain a high growth rate of 20% over the next decade, with the scale expected to approach 18 billion USD by 2035.The regional pattern of North America's dominance, Europe's stability, and the Asia-Pacific's acceleration is clear. As materials, equipment, and certification systems continue to improve, 3D printing will play an irreplaceable role in the manufacturing of prototypes, tooling, and even critical flight components, becoming an essential pillar of the next generation of the aviation and aerospace industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories