Changchun Institute of Applied Chemistry's Zhongbao Jian Team Angew: Creation of New Generation Polyolefin Catalysts

Polyolefins are the most widely produced synthetic resins (250 million tons per year) and the most versatile polymer materials. High-performance ethylene-based copolymers represent the most typical high-end products among polyolefins; they are primarily produced through homogeneous high-temperature solution polymerization, which allows for precise control over the polymer microstructure. Benefiting from advantages such as low system viscosity, absence of polymer precipitation or fouling, and ease of continuous production, the high-temperature solution polymerization (HTSP) method has become one of the most powerful and influential synthetic technologies for the preparation of high-end polyolefins.

For example, commercially available polyolefin elastomers (ethylene-octene copolymer, POE), olefin block copolymers (ethylene-octene multi-block copolymer, OBC), and cyclic olefin copolymers (ethylene-cyclic olefin copolymer, COC) are all industrially produced via high-temperature solution copolymerization technology (100-150 °C). The high-temperature solution polymerization methods for synthesizing POE, OBC, and COC benefit primarily from the continuous iteration of high-temperature resistant metallocene catalysts. However, when it comes to the synthesis of ethylene-acrylate copolymers (EMA and EBA; a class of the most industrially promising high-end polyolefins among ethylene-polar olefin copolymers, suitable for power grid insulation cable materials), metallocene catalysts, which have been developed for more than 40 years, are helpless. Therefore, a new generation of polyolefin catalysts urgently needs to be developed.

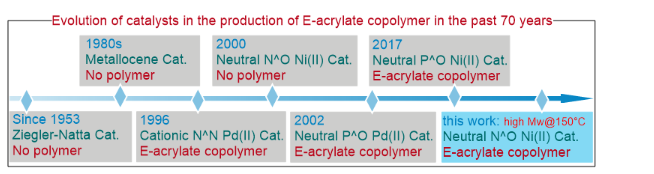

Based on the coordination-insertion polymerization mechanism, the high-temperature solution copolymerization of ethylene with acrylates is one of the most promising yet challenging reactions in the fields of chemistry and catalysis. To date, early transition metal and rare-earth metal catalysts have remained ineffective for the synthesis of ethylene-acrylate copolymers; however, the emergence of late transition metal catalysts has brought a turning point. In 1996, cationic α-diimine palladium catalysts achieved the synthesis of branched ethylene-acrylate copolymers for the first time, and in 2002, neutral phosphine-sulfonate palladium catalysts enabled the first synthesis of linear ethylene-acrylate copolymers. Nevertheless, palladium catalysts are prohibitively expensive and, more critically, can only produce ethylene-acrylate copolymers with extremely low molecular weights at high temperatures (≥ 100 °C).

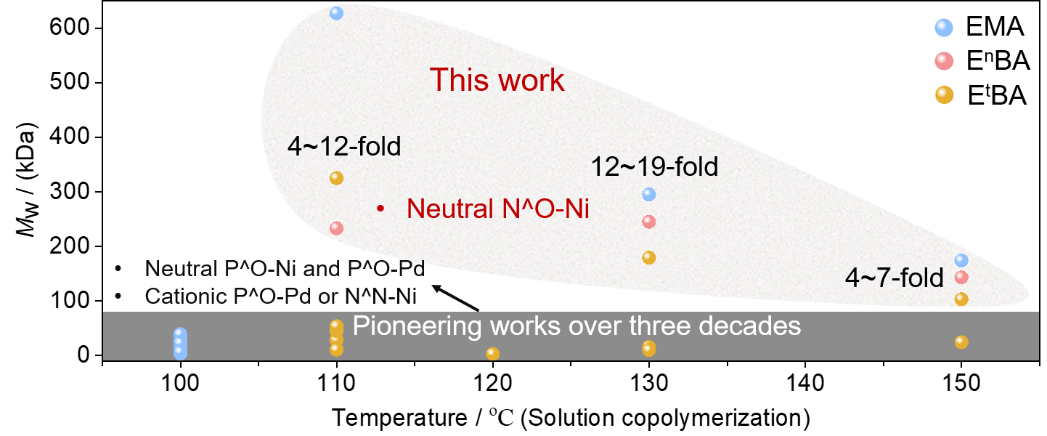

In contrast, nickel catalysts offer a superior solution for the copolymerization of ethylene with acrylates; however, the higher oxophilicity of nickel catalysts makes copolymer synthesis extremely challenging. For instance, classical neutral salicylaldiminato nickel catalysts remain ineffective. The emergence of neutral phosphine-phenolate nickel catalysts in 2017 greatly promoted the efficient copolymerization of ethylene and acrylates; however, the polymerization performance of these catalysts at high temperatures is still underdeveloped. For example, even with current catalysts, only low-molecular-weight linear ethylene-acrylate copolymers (< 55 kDa) can be synthesized at high temperatures (≥ 100 °C), which severely limits the mechanical properties of the copolymer materials (Figure 1). The synthesis of high value-added ethylene-acrylate copolymers using the industrially preferred HTSP technology still faces significant chemical and catalytic hurdles, including low catalyst thermal stability and low polymer molecular weight at high temperatures. This requires addressing three key issues simultaneously: improving catalyst thermal stability, enhancing tolerance to polar functional group poisoning, and suppressing chain transfer reactions at high temperatures.

Figure 1. 70-year development history of ethylene-acrylate copolymer catalysts.

Professor Zhongbao Jian's team at the State Key Laboratory of Polymer Science and Technology, Changchun Institute of Applied Chemistry, Chinese Academy of SciencesDedicated to the fundamental science and application research of high-performance polyolefins. Addressing the above challenges, the team recently proposed a new generation of polyolefin catalyst design principles (easy to synthesize, easy to regulate, air-stable, high thermal stability), and developed a synergistic enhancement strategy, and for the first time reported a revolutionary neutral N^O-type α-ketoamide nickel catalyst platform.

On January 27, 2026, this research achievement was published under the title "A Facile Neutral Nickel Catalyst Platform for High-Temperature Solution Copolymerization of Ethylene and Acrylate." Angew. Chem. Int. Ed.The corresponding author of the paper in the journal is Jianzhong Bao, Researcher, and the first author is Dr. Xiaoqiang Hu; the DFT calculations in the paper were performed by collaborator Professor Xiaohui Kang.

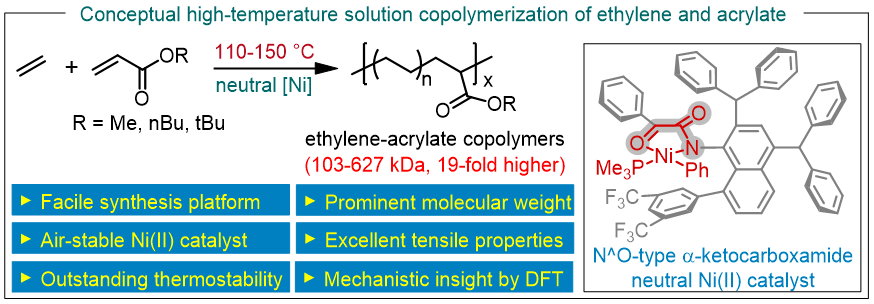

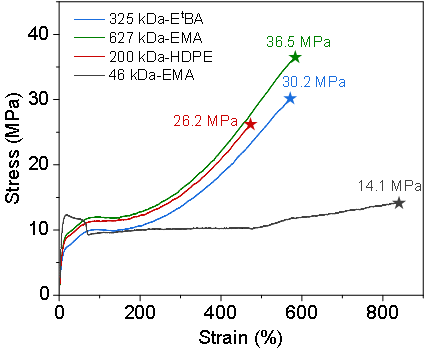

This nickel catalyst platform can catalyze the high-temperature solution copolymerization of ethylene and acrylate to produce high-molecular-weight ethylene-acrylate copolymers (Figure 2) without the need for alkylaluminum as a scavenger and cocatalyst. In the industrially preferred high-temperature range (110-150 °C), high-molecular-weight (103-627 kDa) ethylene-acrylate copolymers were synthesized with a breakthrough, achieving a maximum molecular weight increase of up to 19 times (Figure 3). This shift from low to high molecular weight is crucial for practical industrial applications, endowing the ethylene-acrylate copolymer materials with excellent mechanical properties (Figure 4).

Figure 2. N^O-type neutral nickel catalysts for ethylene-acrylate high-temperature solution copolymerization.

Figure 3. Comparison of molecular weights of ethylene-acrylate copolymers synthesized at high temperatures using the catalyst developed in this work and previously reported nickel/palladium catalysts.

Fig. 4. Mechanical properties comparison of ethylene-acrylate copolymers with different molecular weights

For the past 30 years, N^O-type neutral nickel catalysts (e.g., Grubbs nickel catalysts) were generally considered incapable of achieving ethylene-acrylate copolymerization. This work not only breaks this inherent perception but also achieves higher molecular weights for ethylene-acrylate copolymers synthesized at high temperatures than those obtained with previously developed nickel and palladium catalysts. DFT calculations combined with experimental mechanistic verification explain the importance of α-ketoamide ligand design and reveal a new dormant state mechanism and feasible reaction pathways for high-temperature ethylene-acrylate copolymerization. The synthesis of a new generation of nickel catalysts and the proposed HTSP polymerization method will contribute to the efficient synthesis of polar polyolefins. This study advances the industrial preparation of high-performance ethylene-acrylate copolymer materials through breakthroughs in catalyst synthesis and polymerization methods.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories