Experimental Study on Volatile Organic Amines in Vehicle Air and Interior Materials

With the rapid development of the automotive industry, the issue of interior odors has become a focal point for consumers, with volatile organic amines identified as key odor-causing factors that pose potential health threats to consumers. This study established a method for collecting volatile organic amines in vehicle cabin air and emissions from interior materials using amine sampling tubes, and simultaneously determining the content of multiple volatile organic amines using ultra-high performance liquid chromatography-tandem mass spectrometry. The method has a low detection limit of 2 μg/m³, with good precision (RSD < 5%) and spiked recovery rates (92% to 108%), meeting the daily detection and analysis needs for vehicle cabin air and interior materials. Detection results across various vehicle models and interior materials indicate that volatile organic amine pollution in vehicle cabins is closely related to the type of vehicle and interior materials, with polyurethane foam and EPDM products being the main sources of emissions. It is recommended to promote amine-free vulcanization systems for rubber and plastic products in material processes and optimize polyurethane foaming technology; consumers should enhance ventilation during the initial use of new cars. This study provides scientific basis and technical support for improving vehicle cabin air quality, which is of great significance for safeguarding consumer health.

Bag method; In-car air; Organic amines; Interior materials; Ultra-performance liquid chromatography-tandem mass spectrometry (UPLC-MS/MS)

In today's society, cars have deeply integrated into people's daily lives and become an indispensable means of transportation. With the rapid development of the automotive industry towards intelligence and lightweight design, consumers' demands for driving experience are increasingly higher, shifting focus from traditional vehicle performance indicators, such as power and handling, to the health of the in-car environment. In-car air quality, as a key factor affecting driving comfort, has received increasing attention. In recent years, the issue of peculiar odors inside cars has sparked widespread controversy, persistently troubling many consumers, and its severity should not be underestimated. According to statistics from the China Consumers Association, by the end of December 2021, the cumulative number of complaints about in-car odors in China had reached tens of thousands [1]. In-car odors not only greatly reduce the driving experience but also pose potential threats to consumers' health. Prolonged exposure to a car environment with odors may lead to symptoms such as dizziness, nausea, and respiratory discomfort, and even trigger more serious health issues, such as respiratory system diseases and neurological damage [2-3].

Volatile organic amines are one of the key factors causing interior odors in vehicles. Their sources are extensive and complex, with interior materials being the primary source of release. During the production of seat leather and synthetic leather, various additives and solvents are used to meet specific performance requirements, and these substances may continue to release volatile organic amines inside the vehicle. Similarly, during the processing of plastic and rubber products, some chemicals that might produce organic amines are introduced. Adhesives used for connecting and securing various components inside the vehicle may also decompose or volatilize to produce organic amines under certain conditions. Foaming materials, such as polyurethane foams used in seats, headliners, and carpets, involve the use of amine catalysts in their synthesis process, which is a significant reason for the production of volatile organic amines [4-8].

These organic amines not only have a strong pungent odor but also possess a certain level of toxicity. For example, small molecule organic amines such as methylamine, dimethylamine, and trimethylamine can irritate the eyes and respiratory mucosa. Long-term exposure may affect the nervous system and hematopoietic system, posing potential health risks to consumers [9-10].

Currently, there are certain norms and standards for the detection and control of volatile organic compounds (VOCs) in vehicles, such as GB/T 27630-2011 "Guidelines for the Evaluation of Indoor Air Quality in Vehicles." Relevant detection standards and methods have gradually been established and improved. However, the existing standards and detection methods have significant limitations, as they only cover eight common pollutants: benzene, toluene, xylene, ethylbenzene, styrene, formaldehyde, acetaldehyde, and propionaldehyde. There is a clear lack of sampling and detection methods for volatile organic amines, which has led to a long-term inability to accurately assess and effectively manage the pollution of volatile organic amines in vehicles. This results in consumers facing unknown risks regarding indoor air quality. Therefore, conducting in-depth research on volatile organic amines in vehicle air and interior materials is of significant practical importance for comprehensively understanding the indoor air quality and protecting consumer health.

In terms of controlling air pollution sources, the currently common sampling tubes and absorbing solutions only target dimethylamine and trimethylamine, such as oxalic acid-glass microsphere sampling tubes and neutral silicone tubes. Among them, the oxalic acid-glass microsphere sampling tube has a validity period of only one month, and the laboratory analysis and testing are relatively complicated, which is not conducive to the analysis of large batches of samples, and the stability of the experimental results is difficult to guarantee. The absorbing solution can solve the problems of sampling efficiency and analytical efficiency, but it is inconvenient for transportation. Therefore, using amine sampling tubes can collect more volatile organic amines, improve sampling and analytical efficiency, simplify subsequent processing, and be convenient for carrying.

1.1 Major Instruments and Equipment

VA-228 Whole Vehicle VOC Environmental Chamber, Dongguan Shengwei; V-BIR-42 VOC Sampling Bag Method Test Chamber, Dongguan Shengwei; 1290-6460 Ultra-High Performance Liquid Chromatography Tandem Mass Spectrometry System, Agilent Technologies, USA; 1000 L, 2000 L, 3000 L Tedlar Gas Sampling Bags; 520H Gas Flow Meter, Mesa Labs, USA; Gilair Plus Air Sampling Pump, Gilian Company, USA; 0.22 μm Syringe PTFE Filter Membrane, Shanghai Anpu; Amine Sampling Tube (Laboratory-made).

1. 2 Reagents

Methanol (HPLC grade), formic acid (HPLC grade), first-grade water, and formic acid-methanol-water solution (volume ratio of methanol:water:formic acid = 1:1:0.2): Measure 100 mL of methanol and water, and 20 mL of formic acid into a 500 mL beaker, stir evenly with a glass rod, and sonicate.

1.3 Gas Sample Collection

1.3.1 Collection of Vehicle Interior Air Samples Park the vehicle in an environmental chamber for sampling. Refer to the pretreatment method for sampling and determination of volatile organic compounds and aldehydes and ketones in vehicle interiors as per HJ/T 400-2007 [15]. Set the sampling flow rate to 1000 mL/min and the collection time to 60 minutes. Record information such as sampling time, date, temperature, and atmospheric pressure during sampling. After collection, seal both ends of the sampling tube and send it to the laboratory for analysis. Samples that cannot be analyzed immediately should be stored at 0-4°C, with a maximum storage duration of no more than 7 days.

1. 3. 2 Collection of Interior Material Samples

Place the interior materials into a cleaned Tedlar bag, fill the bag with 30% to 50% volume of high-purity nitrogen, evacuate it, and repeat the process 3 times. Finally, fill the bag with 50% volume of high-purity nitrogen and place it in the VOC sampling bag method testing chamber at a constant temperature of 65°C for 2 hours. Before the end of the constant temperature period, 10 minutes prior, knead and pat the heated sampling bag to mix the gas inside evenly. Then, using an amine sampling tube, set the sampling flow rate to 100 L/min and collect for 60 minutes.

1. 4 Amino Sampling Tube Elution

Attach one end of the amine sampling tube closely to the inner wall of the colorimetric tube, and slowly add a total of 5 mL of methanolic formic acid solution into the amine sampling tube in 3 separate portions. During this process, use the wooden end of a cotton swab to expel the solvent adsorbed on the glass wool of the amine sampling tube. Filter the eluent through a 0.22 μm PTFE syringe filter into a 2 mL sample vial, and then analyze using ultra-high performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS).

Chromatographic conditions 2.1

Chromatographic column selection: Agilent Poroshell 120 SB-Aq, 3.0 mm × 150 mm, 2.7 μm or equivalent; set the injection volume to 1 μL; column temperature controlled at 40°C; flow rate set to 0.40 mL/min. Mobile phase A is 0.1% formic acid in water; mobile phase B is methanol. A gradient separation method is used, with an initial ratio of φ(A) = 100% maintained for 3 min. Within 1 min, the proportion of mobile phase A, φ(B), is increased to 50%; within 2.5 min, the proportion of mobile phase B, φ(B), is increased to 100% and maintained for 1.5 min; within 8.1 min, the proportion of mobile phase A, φ(B), is increased to 100%, held until 10 min. Through gradient elution, effective separation and detection of various volatile organic amines are achieved.

2.2 Mass Spectrometry Conditions

Capillary voltage for mass spectrometry is set to 3500 V; desolvation gas temperature is 350 ℃; desolvation gas flow rate is 13 L/min; sheath gas temperature is 360 ℃; sheath gas flow rate is 11 L/min; using multiple reaction monitoring mode.

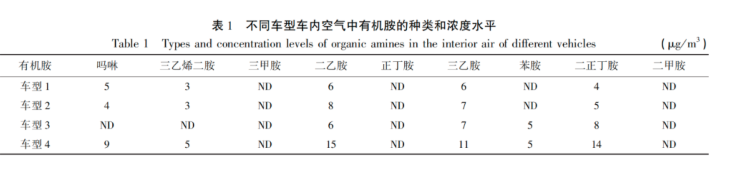

The detection results of volatile organic amines in the car interior air are shown in Table 1.

ND indicates not detected (<2 μg/m³). The organic amines involved include pyridine, triethylenediamine, trimethylamine, diethylamine, n-butylamine, triethylamine, aniline, dibutylamine, and dimethylamine. There are differences in the concentrations of organic amines across different vehicle models, which may be related to factors such as the choice of interior materials, manufacturing processes, and years of use. The detection of diethylamine and triethylamine in several vehicle models indicates that these two organic amines are relatively common in the vehicle interior air.

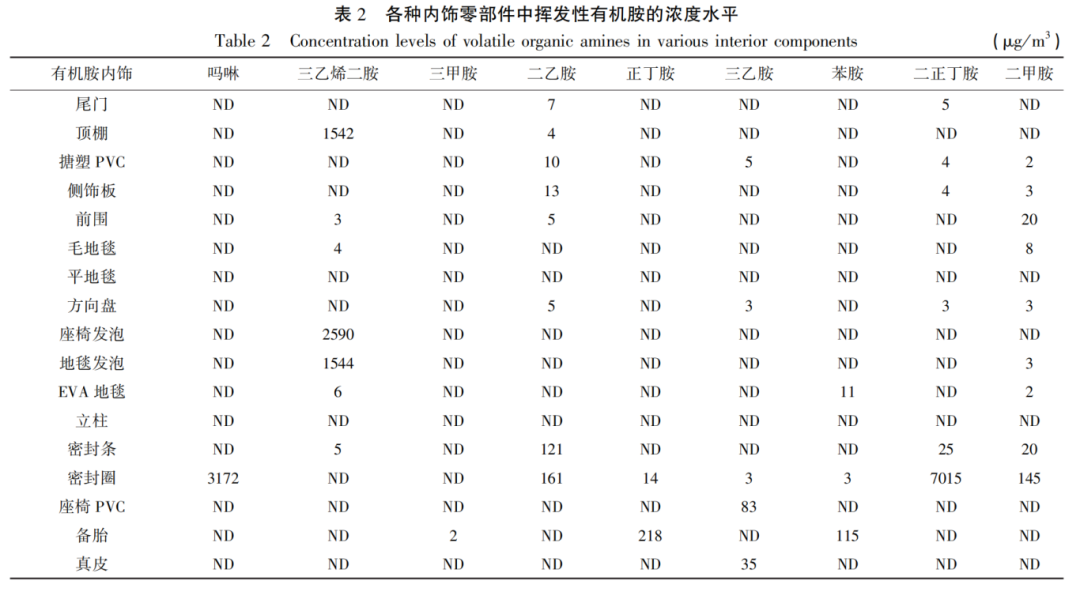

The concentration levels of volatile organic amines in interior materials are shown in Table 2.

The results show that there are significant differences in the distribution of organic amines among different interior materials. For example, no volatile organic amines were detected in materials such as pillars and flat carpets, which may be due to the fact that these materials did not use raw materials that would produce organic amines during production, or their release amounts are extremely low. Triethylenediamine was detected at the highest levels in seat foams, headliners, and carpet foams, as these materials heavily utilize polyurethane foaming materials, and the amine catalysts used in the polyurethane synthesis process are the reason for the presence of triethylenediamine. In side trim panels, steering wheels, EVA carpets, sealing strips, sealing rings, and spare tires, three or more volatile organic amines were detected, with the sealing ring reaching seven types.

From the perspective of interior materials, plastic materials do not use amines or catalysts in their production processes, so the contribution of volatile organic amines may come from PVC, adhesives, and so on. The headliner, seats, and carpets heavily utilize polyurethane foam materials, and the generation of volatile organic amines primarily comes from the amine catalysts used in the polyurethane synthesis process. The production of volatile organic amines in sealing strips and sealing rings mainly results from the complex production processes of EPDM materials. This provides a direction for further controlling the release of volatile organic amines in vehicles, indicating the need to focus on material selection and production process optimization.

4.1 Research Conclusions

This study established a synchronous detection method for various volatile organic amines in indoor air and interior materials based on ultra-high performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS). The method features simple sampling operations, low detection limits of 2 µg/m³, and meets the routine analytical requirements for volatile organic amines with precision (RSD < 5%) and spiked recovery rates (92% - 108%).

Experimental data indicate that the pollution of volatile organic amines inside vehicles is closely related to the car model and the type of interior materials. Different car models use different interior materials and production processes, resulting in variations in the types and concentrations of volatile organic amines inside the vehicle. Polyurethane foam and EPDM products are the main sources of volatile organic amines. Polyurethane foam materials are widely used in car seats, headliners, carpets, and other parts, and the amine catalysts used in their synthesis process are significant sources of volatile organic amines. EPDM materials are used in seals, gaskets, and other components, and their complex production process can generate a variety of volatile organic amines. Therefore, in the automobile manufacturing process, special attention should be paid to the selection of catalyst systems and additives in the production of polyurethane foam and EPDM products to reduce the generation of volatile organic amines from the source.

4.2 Suggestions for Improving Air Quality in Vehicles

4. 2. 1 Material Process Optimization

In the production of rubber and plastic products, the promotion of amine-free vulcanization systems (such as peroxide cross-linking) is actively encouraged. Traditional amine-containing vulcanization systems release volatile organic amines during the vulcanization process, while the use of amine-free vulcanization systems such as peroxide cross-linking can effectively avoid this issue.

For polyurethane foam materials, it is recommended to use physical foaming technology instead of chemical foaming. Additionally, developing metal-based environmentally friendly catalysts to replace traditional amine catalysts can ensure the performance of polyurethane foam materials while reducing the residual amount of organic amines.

4.2.2 Consumer Protection Tips

During the initial use of a new car, consumers should make full use of the vehicle's ventilation system to enhance air circulation inside the car. When parking, try to choose well-ventilated areas, and open the windows or sunroof to allow for adequate airflow between the interior and the outside. While driving, use the outside air circulation function reasonably to bring fresh air into the car and expel odors and harmful gases. Especially in high temperature weather, it is crucial to strengthen ventilation, as high temperatures can accelerate the release of volatile organic amines. Timely ventilation can effectively reduce the concentration of organic amines and VOCs inside the car.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories