VAMA's "Yujian" Philosophy: The Car-Making Wisdom of a Leader in Hot-Formed Steel

In the wave of electrification and intelligentization, the automotive industry is undergoing profound transformation. As factors like range, smart cockpits, and intelligent driver assistance become focal points of competition, body materials, as the "skeleton" of vehicles, are being redefined in their strategic importance. How can manufacturers achieve extreme lightweighting while ensuring safety, controlling costs, and supporting flexible manufacturing across multi-platform and multi-energy models? This series of seemingly contradictory demands constitutes the core challenges faced by vehicle manufacturers.

In this context, Hunan Valin ArcelorMittal Automotive Steel Co., Ltd. (VAMA), with its profound expertise in hot forming materials and technology, has become a key force driving industry breakthroughs. Leveraging ArcelorMittal's globally leading capabilities in hot forming materials and technology, VAMA has been tasked since its inception with the mission of introducing world-class automotive steel technology and solutions into the Chinese market.

VAMA has always positioned itself to provide comprehensive steel solutions for the Chinese automotive industry, rather than merely being an advanced materials supplier. Mr. Pedro Raiser, the company's Chief Marketing Officer, stated in an exclusive interview with Gaishi Automotive: "We are witnessing a shift in the industry from material innovation to solution innovation. If a company cannot transform into a comprehensive solution provider and collaborate with customers for innovation, it will be difficult for any business to survive."

This insight is precisely the strategic cornerstone of VAMA's collaboration with downstream processing service center GONVVAMA (Hu'an Steel Baoli, a joint venture between VAMA and Steel Baoli) to launch the Yu Jian™ multi-part integration solution. This solution integrates multiple components through modular design, reducing the number of parts and simplifying assembly processes, thereby enhancing production efficiency, lowering costs, and improving the overall vehicle performance and reliability. Since its release at this year's Shanghai Auto Show, the solution has quickly gained industry recognition, helping VAMA win the "2025 Seventh Golden Gear Award—Top 100 New Automotive Supply Chain Award in China" from Gasgoo Auto.

In this transformation that reshapes the automotive "body," VAMA leverages the synergy of globally leading technology and localized innovation, becoming an important force in driving the development of next-generation body technology.

I'm sorry, but it seems like there is no specific content provided for translation. Could you please provide the text you would like me to translate into English?Hot-formed steel enters a "new application era."

In the traditional logic of automobile manufacturing, hot-formed steel, due to its ultra-high strength, is often used as a high-performance safety structural material to enhance safety performance. However, as electrification platforms demand higher overall structural efficiency, safety standards, and body lightweighting, the role of hot-formed steel is undergoing a fundamental elevation.

In this transformation process, VAMA, leveraging its deep accumulation and continuous innovation in the field of hot stamping, has not only advanced the progress of materials but also redefined the role of hot-stamped steel in the overall vehicle structure. It has evolved from being merely scattered "reinforced bones" to becoming an integrated "fundamental framework" for constructing the next generation of car bodies.

1. From safety structural components to "skeletal network"

In the past, OEMs used hot-formed steel in key structural areas of the car body—such as the A-pillar and B-pillar—primarily considering local strength and collision safety. Nowadays, relying on shareholder ArcelorMittal's leading position in the global hot-forming technology field, VAMA is actively collaborating with Chinese car companies to elevate the application of hot-formed steel from local reinforcement to a system-level and platform-level approach, demonstrating strong capabilities in technological leadership and application innovation.

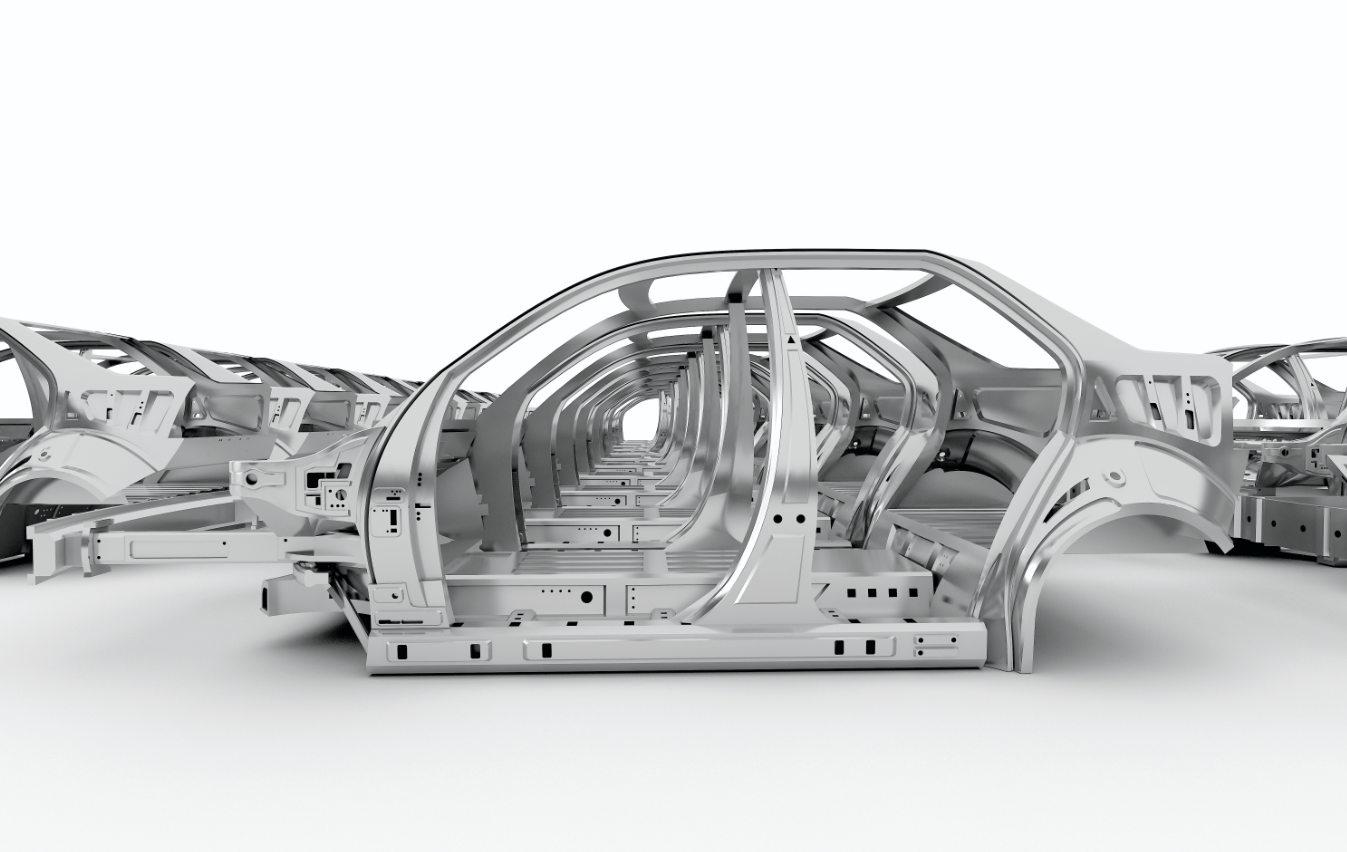

A quintessential example is the popularity and iteration of the "door ring" concept. From the initial single door ring launched by ArcelorMittal in North America, it has now evolved into an "inner and outer double door ring" structure that covers the A-pillar, B-pillar, and even the C-pillar. Hot-formed steel is made into integrated or a few large components through laser welding technology, replacing the originally scattered dozens of parts.

Image source: VAMA

"ArcelorMittal is a pioneer in the research and development of door ring systems and hot-formed materials," Pedro said while reviewing the technological development process. "As an important part of its strategy in the Chinese market, VAMA and GONVVAMA have introduced and continuously iterated this solution."

This integration is far from a simple assembly of parts; it involves VAMA's precise integration of various advanced processes for steel plates of different thicknesses, strengths, and even coatings. By integrating materials such as ultra-high-strength Usibor® (suitable for intrusion-resistant areas) with highly ductile Ductibor® (suitable for energy-absorbing areas), VAMA can truly achieve the goal of "using the most suitable steel in the most appropriate location."

This "material customization" allows the entire vehicle sidewall and other body modules to function as a continuous and efficient whole to bear and transmit collision energy: ensuring extremely high rigidity at critical stress points to resist deformation, while effectively dissipating impact forces in the predetermined energy absorption zones through the excellent ductility of the materials. As a result, not only is vehicle weight successfully reduced, but safety is not compromised; instead, the overall rigidity and collision safety of the vehicle body are systematically and significantly enhanced, precisely achieving an optimal balance between safety, lightweight design, cost, and component performance.

Similar integration logic extends to other key areas of the vehicle body, such as the rear body skeleton (H-beam). It integrates what used to be up to 11 parts into one, achieving a weight reduction of over 10%. Moreover, due to its modular characteristics, it can flexibly adapt to different wheelbases and styles of vehicles on the same platform.

The emergence and popularization of these "super-integrated" structures signify that, under the promotion of VAMA, thermoformed steel has evolved from a former "reinforcement role" to become the "skeletal network" supporting modern electric vehicle platform architecture. It is no longer a scattered "reinforcement component" throughout the vehicle body, but rather constitutes a continuous, efficient, and safe load-bearing system.

2. Positioning of Hot-Formed Steel: Value Trade-offs in a Multi-Dimensional Coordinate System

As aluminum and composite materials attract considerable attention in the industry due to their lightweight characteristics, what is the competitive positioning of steel—especially hot-formed steel?

In response to this core issue, Pedro's answer demonstrates a calm strategic perspective. He pointed out that assessing the value of a material cannot be based on a single criterion but should be placed within a multi-dimensional coordinate system that includes cost, safety, environmental impact, reparability, and overall design flexibility.

"We believe its advantages are reflected in multiple dimensions: firstly, it is more cost-effective; secondly, it performs better in terms of safety; and it also meets environmental requirements more effectively," Pedro pointed out. "Compared to aluminum and composite materials, hot-formed steel also has significant advantages in terms of repairability."

This embodies the philosophy of Yujian™: by "placing the most suitable steel in the most suitable position," leveraging system-level integrated design to fully utilize the comprehensive advantages of hot-formed steel in terms of strength, formability, environmental protection, and reparability. This achieves the optimal balance between lightweight, safety, cost, and environmental considerations, thereby significantly enhancing the overall vehicle manufacturing efficiency.

Image Source: VAMA

Specifically, from the perspective of material performance, hot-formed steel exhibits exceptional strength. For example, the Usibor® series promoted by VAMA has a tensile strength of up to 2000 MPa, which is significantly higher than most aluminum and composite materials, providing excellent intrusion resistance for critical areas of the vehicle body. Meanwhile, the Ductibor® series maintains high strength while exhibiting excellent toughness, making it particularly suitable for energy-absorbing zone designs. This combination of "rigidity and flexibility" allows designers to simultaneously achieve high rigidity protection and efficient energy absorption within the same structure, systematically enhancing the overall safety level of the vehicle.

In terms of formability, hot-forming steel can precisely integrate steel plates of different thicknesses, strengths, and even different coatings into a unified component through advanced processes such as laser welding. By using direct hot-forming techniques, it achieves better forming performance than cold-formed high-strength steel, enabling high-precision manufacturing of complex geometries. This not only expands the freedom of vehicle body design but also significantly improves material utilization and structural integrity, avoiding the common connection weaknesses and compatibility issues found in mixed-material structures.

Steel itself has extremely high recyclability and is a key material in the circular economy in terms of sustainability. VAMA actively assists customers in achieving carbon neutrality by promoting the efficient use and recycling of hot-forming steel. In addition, by reducing the number of parts and welding processes through integrated design, it directly reduces energy consumption and carbon emissions in the production process, achieving full-chain green optimization from material selection to manufacturing processes.

It is worth emphasizing that hot-formed steel also has significant advantages in repairability. Compared to aluminum and composite materials, steel has more mature repair processes, lower costs, and is easier to replace and repair in the aftermarket. This not only reduces the lifetime usage cost of the vehicle but also positively impacts insurance expenses and used car residual value, bringing tangible economic benefits to end-users.

The "precise material utilization" strategy based on systems engineering thinking allows VAMA's hot forming steel solutions to demonstrate strong adaptability in the electrification era. Pedro specifically used the chassis as an example to illustrate this trend: "Take the chassis system as an example, our ongoing H-beam steel solution indicates that in the long run, hot forming steel, with its comprehensive advantages in structural safety, cost, and sustainability, will still be the preferred material for OEMs."

When lightweighting is no longer simply about "reducing weight," but evolves into a comprehensive pursuit of structural safety, efficiency, cost control, and sustainability, VAMA continues to strengthen its industry leadership in the fierce material competition through its profound understanding and innovative application of the comprehensive performance of hot forming steel.

3. Electrification New Track: "Cost and Safety Optimal Solution" for Battery Packs

As the demand for battery safety in electric vehicles becomes increasingly stringent and the need for platform-based production to dilute costs becomes more pressing, the application scenarios for hot-formed steel are being elevated by the wave of electrification. In this field, VAMA once again demonstrates its technological foresight by extending the application of hot-formed steel from passenger cabin protection to the vehicle's most expensive core component—the power battery, further consolidating its central position in the integrated body structure.

While the industry generally focuses on lightweight battery packs and increasingly adopts aluminum materials, VAMA has provided a more comprehensive steel solution from the perspectives of overall economy and safety assurance. Pedro revealed, "VAMA has currently supplied steel components for the bottom structure of the battery pack. In addition, we have developed a complete structural solution for the battery pack framework to respond to the industry's core demands for 'high safety, high performance, and low cost'."

He further highlighted the core value of the solution with specific data: "This solution reduces the overall structural cost of battery packs by more than 40% while achieving higher safety assurance. It provides OEMs, who are seeking breakthroughs in intense cost competition, with a reliable option that balances core performance and economic benefits."

At the same time, the high requirements for overall structural safety and modular compatibility of the electrification platform further amplify VAMA's expertise in integrated design of the vehicle body. As mentioned earlier regarding the integrated H-beam solution, it not only achieves weight reduction and cost savings but essentially constructs a vehicle body "skeleton" with higher rigidity and better integrity. This integrated structure can more effectively manage collision energy, providing a sturdy "protective shield" for the battery pack at the bottom, minimizing the risk of deformation intrusion during collision scenarios.

It is evident that the trend of electrification has not diminished the value of hot-formed steel; instead, it has created broader application prospects by generating new demands such as battery pack protection, integrated structures, and highly versatile platforms. VAMA is leveraging its technological leadership to ensure that hot-formed steel continues to play an important role in the era of new energy vehicles.

From Concept to Mass Production: The Art of Simplification™ Path

In VAMA's strategic vision, YuJian™ is not merely the name of a technical solution, but represents a philosophy of restructuring automotive manufacturing processes through integrated thinking. Its core lies not in the mere reduction of parts, but in fundamentally transforming design thinking to integrate material characteristics, process potential, and vehicle performance requirements, thereby reducing manufacturing complexity at the source.

The implementation of this design philosophy is supported by VAMA's continuous innovation in advanced hot stamping steel materials, relying on precision manufacturing processes such as laser welding, pushing the boundaries of material performance to the extreme. Through laser welding technology, steel plates of different thicknesses, strengths, and even coatings are precisely joined together to form a "custom blank." Subsequently, through a one-time hot stamping process, this blank is transformed into a large integrated component with excellent performance. This process replaces the traditional mode, which requires multiple molds, multiple stamping, and extensive welding, fundamentally achieving the integration of parts from the source.

Pedro specifically mentioned that in the manufacturing of multi-component integrated sheet metal, "the process that originally required over 130 welding points has now been replaced by a few laser weld seams." This transition from "multi-point welding" to "linear welding" not only improves the consistency of strength at the connecting parts but also significantly reduces the risk of errors caused by complex welding processes, making the entire vehicle manufacturing process more precise and reliable.

Image Source: VAMA

Based on the design philosophy and technology mentioned above, the integrated design of Yujian™ has permeated various key areas of the body-in-white. In addition to iconic applications such as door rings, H-beams, and battery pack frames, the sunroof ring utilizing the Yujian™ solution optimizes material layout through laser welding technology, enhancing top pressure performance while significantly reducing the carbon footprint during the production process. The Yujian™ front panel integrates eight components into one, not only streamlining over 70 welding points and improving manufacturing efficiency but also enhancing overall strength.

Image source: VAMA

The value brought by this deep integration is multidimensional and diverse. Pedro further elaborated on how the Yujian™ solution, through its highly integrated design, reshapes the core aspects of the manufacturing process. Using the H-beam as an example, he pointed out that this integrated solution not only streamlines the number of components but also drives the optimization of the entire production chain: "In terms of human resource allocation, this solution can reduce the number of operators by nearly 30%; in terms of the area occupied by the body shop, it can reduce space usage by up to 40%." This means that when OEMs implement new platforms, they can significantly reduce upfront investment while achieving higher output with a more compact production line layout.

In addition to directly improving production efficiency, the Yujian™ solution also demonstrates significant advantages in sustainable manufacturing. Pedro pointed out that "integrated multi-part solutions using high-strength steel can achieve weight reductions of up to 14% and a 15% reduction in the number of parts." Behind this data lies not only breakthroughs in the lightweight properties of the material itself but also a "burden reduction" achieved through system design—fewer parts mean simplified material management and lower storage and logistics costs.

The concept of YuJian™ is reflected not only in the efficiency and cost optimization on the manufacturing side but also throughout the entire lifecycle carbon footprint management of products. According to VAMA's plan, the company aims to reduce carbon emission intensity by 50% compared to 2018 by 2030 and has committed to achieving carbon neutrality by 2050. In Pedro's view, the lightweighting effects achieved through the YuJian™ solution are becoming an important driving force for realizing this goal, helping customers reduce vehicle weight while injecting strong momentum into their sustainable manufacturing efforts.

"Hot forming+"Ecological Layout

Under the grand curtain of the revolution in vehicle body materials, VAMA has not confined itself to being a "leader" in a single technological path, but rather it has taken on a more forward-looking role as an "ecosystem builder," driving the value reshaping of steel materials in the automotive industry. At the core of its strategy is the construction of a "hot forming+" ecosystem, which is based on hot forming technology and extends to complete vehicle material solutions.

1. Product Matrix: Beyond Hot Forming

Despite VAMA's market reputation with star hot-forming products like Usibor® and Ductibor®, the breadth of its product system extends far beyond this. According to Pedro, VAMA positions itself as a "provider of comprehensive material solutions," committed to developing a material spectrum that covers all critical needs. For instance, in the cold-forming sector, its advanced high-strength steel (AHSS) reaches a strength of 1200 MPa; whereas in the hot-forming sector, products like Usibor® 2000 achieve even higher strength levels, collectively meeting the diverse requirements for strength, formability, and safety in various parts of the car body.

This product layout that goes "beyond just hot forming" reflects VAMA's profound understanding of the complexities of automotive manufacturing. The company not only possesses its own "ace materials," but also provides customers with optimal overall solutions through a flexible "material combination strategy." As Pedro stated, "We must focus on the entire vehicle ecosystem— we have a diverse range of solutions suitable for different parts of the vehicle, and these solutions do not all rely on hot forming technology."

The development of the white body is a complex system engineering project. VAMA is able to take a global approach to match the most suitable materials for each part: for example, using the Usibor® series in areas requiring extremely high strength, utilizing the Ductibor® series in sections that demand efficient energy absorption, and complementing these with advanced cold-formed steel.

This is also a concrete reflection of the Yu Jian™ philosophy at the product level—rather than pursuing a singular extreme of technology, it aims to simplify complexity by precisely matching materials and integrating systems, helping manufacturers find the best balance among lightweight design, safety, cost, and manufacturability.

2. Global technological accumulation, localized customization empowerment.

Having a comprehensive product matrix is akin to a warrior mastering eighteen types of weapons. However, truly defeating the enemy on the battlefield requires exquisite "inner techniques." For VAMA, these "inner techniques" derive from ArcelorMittal's two-decade-long technical expertise in the field of hot forming and component integration.

Pedro emphasized that VAMA is not a newcomer in providing integrated solutions, but is built on "a very stable, strong, and reliable foundation." The tangible support for this foundation comes from ArcelorMittal's 14 research and development centers located around the world. He pointed out that VAMA can readily access the support of these R&D networks to introduce advanced solutions that have already been successfully validated in overseas markets to local customers in China, thereby creating value. This ensures that the cutting-edge steel solutions gene is always flowing in VAMA's technological bloodstream.

Based on this global foundation, VAMA's core value lies in its ability to deeply integrate and redevelop these global technological reserves with the specific needs of Chinese OEMs.

"Our solutions are highly flexible—from the initial research and development stage, they are not fixed and unchangeable sets of solutions, but rather insist on customization: tailored adaptations for different clients, different needs, and different platforms," said Pedro. This means that VAMA's engineers, in collaboration with ArcelorMittal China's EVI engineering team, will be involved from the design stage, working closely with OEM clients to develop 'customized solutions and exclusive components' for specific models and platforms based on a universal conceptual framework.

Through this deep integration with OEMs and front-end collaboration, VAMA has successfully transformed ArcelorMittal's validated global technological solutions into tangible results that meet the stringent requirements of China's automotive industry for cost, efficiency, and innovation. This has realized a value elevation from "technology introduction" to "ecosystem empowerment."

3. Expansion of production capacity and supply assurance alongside localized research and development.

The comprehensive product matrix and in-depth localization collaboration ultimately require solid capacity assurance and continuous innovation momentum as support. To this end, VAMA is building future-oriented core competitiveness through proactive capacity expansion and deepened research and development layout.

Image Source: VAMA

With the full commissioning of the second-phase project in April 2023, VAMA's supply chain assurance capability has reached a new level. This not only provides reliable assurance for the large-scale delivery of advanced solutions such as Yu Jian™, but also means that VAMA can support Chinese automotive customers in rapidly launching new models in fierce market competition with more stable and efficient supply. Meanwhile, the company's third-phase project is also progressing in an orderly manner, laying a solid foundation for its future growth and technological upgrades.

However, VAMA's vision does not stop at merely expanding its current scale. Pedro keenly pointed out, "We see that China has become the fastest-growing market for hot forming in the world." To better align with this market trend, VAMA is planning a more far-reaching strategic move—establishing a global R&D center for automotive steel in China.

The core of this initiative lies in achieving "local empowerment of global resources." As Pedro explained, the center will assist VAMA in "accelerating the development and application of localized solutions, thereby creating greater value for customers."

In conclusion:

Throughout VAMA's innovation journey, its core is not merely a simple overlay of technologies, but a value reshaping that starts from materials, succeeds in design, and culminates in ecology. Through the Yu Jian™ integrated solution, VAMA takes on complex challenges itself to deliver simplicity, efficiency, and reliability to its customers. This not only proves the irreplaceable strategic value of hot-formed steel in the electrification era but also collaborates with clients to build a faster-responsive, more cost-effective, and sustainable new manufacturing ecosystem. Looking to the future, with the ongoing integration of local research and global wisdom, VAMA is practicing "mastering complexity with simplicity" to provide a proven and reliable answer for the future of automotive manufacturing.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories