Jiangsu Bell Machinery Co., Ltd.

China JiangsuProvince

Main products

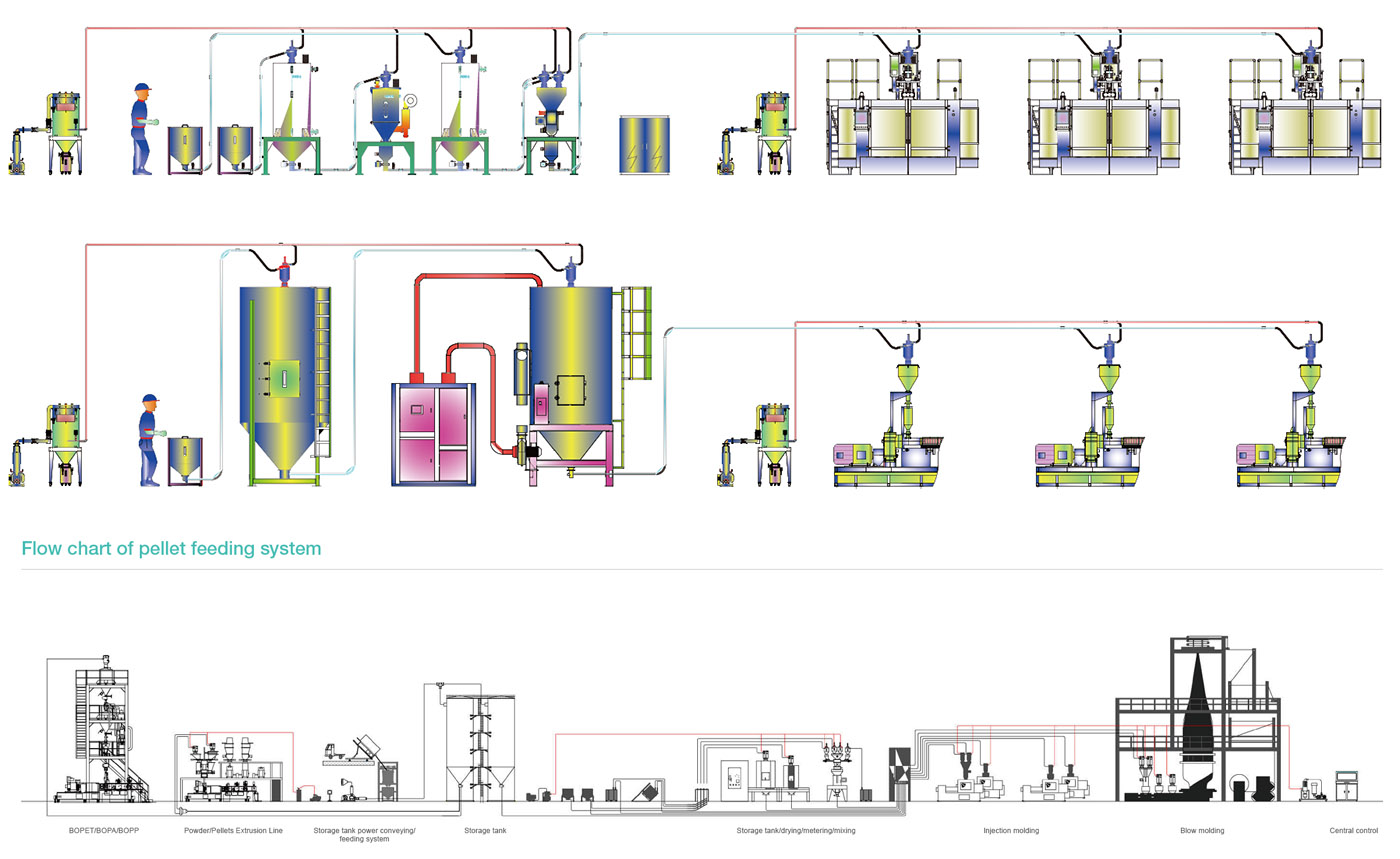

Special pipe equipment, mixing systems, RTP pipe extrusion equipment, high-speed and high-efficiency extrusion solutions, sheet and board equipment, high-output WPC extrusion production lines, extrusion equipment, WPC profile extrusion production lines, cleaning and recycling equipment

About Us

Sure, here is the translation of the provided information:

Zhangjiagang Bel Mechanical Co., Ltd. is one of the top plastic machinery manufacturers in China. Located in Zhangjiagang, a national civilized and hygienic city renowned for its picturesque scenery and home to the country's largest inland port, the company enjoys excellent transportation links. Established in 1998, Bel Machinery has consistently demonstrated excellence through the relentless efforts of its employees. Since 2007, the company has ranked first in export volume among its peers in Zhangjiagang for two consecutive years. Currently, the company has 250 employees, with products exported to 57 countries and regions around the world. The new factory covers an area of 60,000 square meters and boasts state-of-the-art hardware and software facilities, providing a high-quality and comfortable office environment as well as efficient production workshops.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code