Tederic Machinery Co., Ltd.

China ZhejiangProvince

Main products

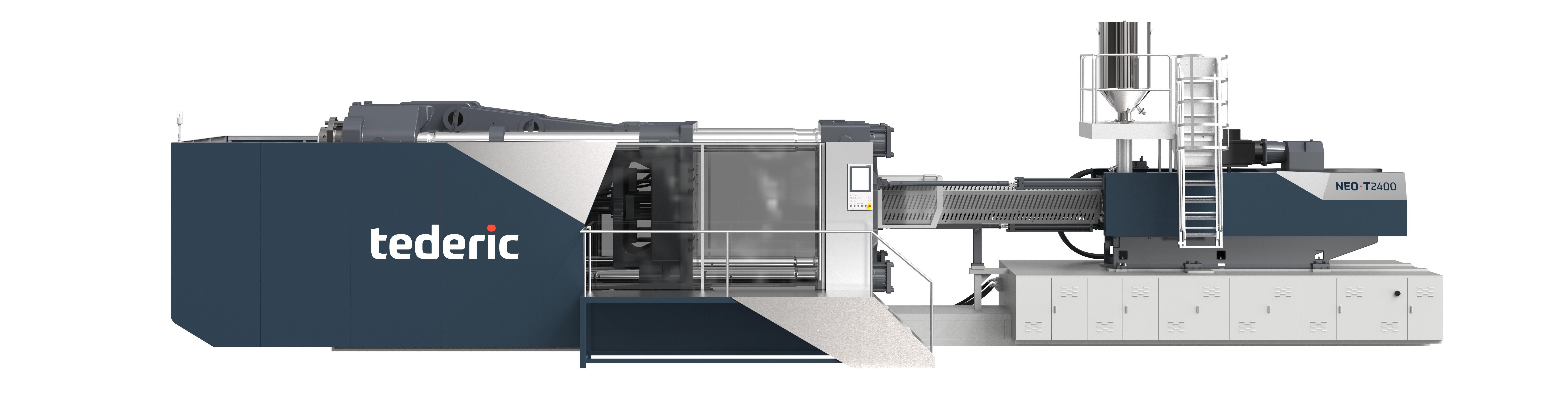

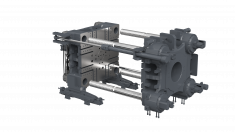

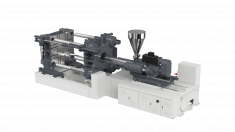

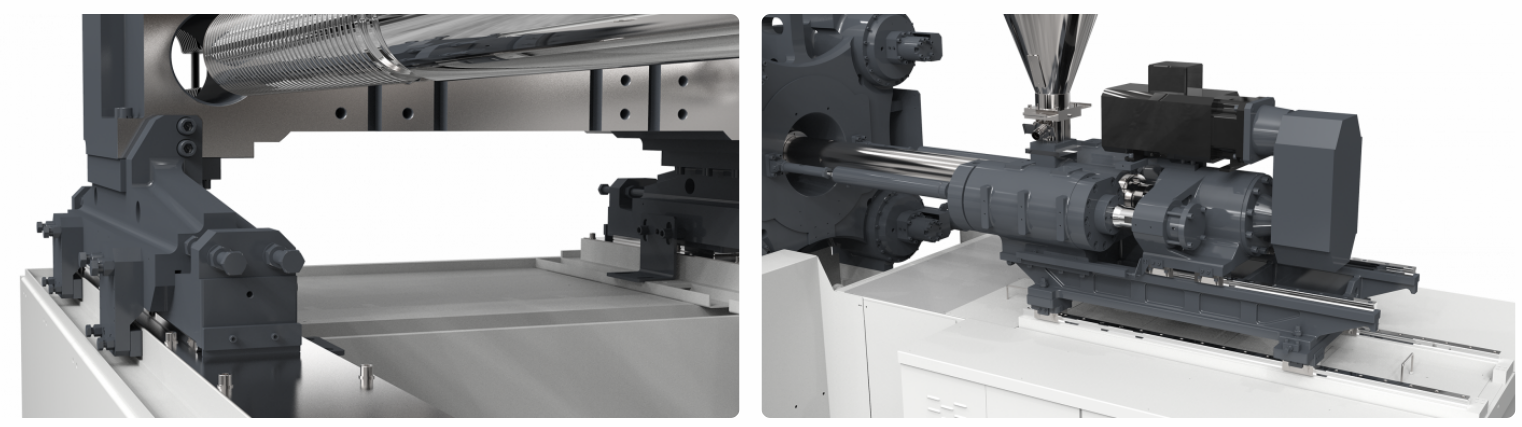

Toggle-type injection molding machine, Electric injection molding machine, Two-platen injection molding machine, Multi-component injection molding machine

About Us

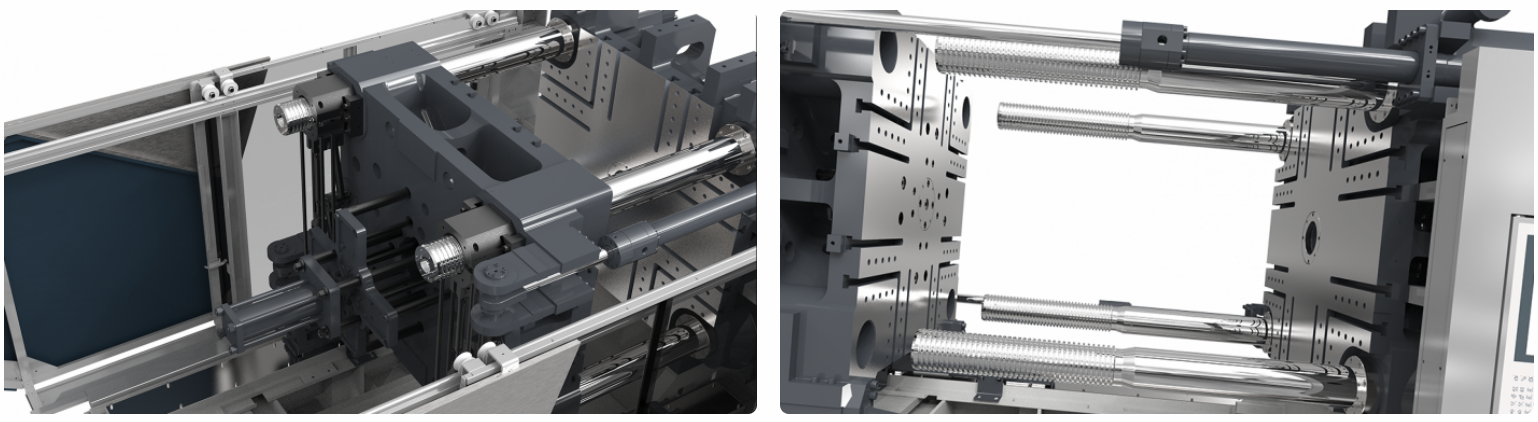

Tederic Machinery has a total investment of 85 million US dollars, and now owns a modern and digital factory covering 150,000 square meters, with an annual production capacity of 10,000 injection molding machines. The company is a national technology enterprise, and its products are now well-known in nearly 90 countries. It comprises: Tederic Machinery Co., Ltd., headquartered in Hangzhou Economic and Technological Development Zone; and Zhejiang Tederic Heavy Machinery Co., Ltd. The company is equipped with dozens of large-scale floor-type CNC boring and milling centers, five-sided and multi-station machining centers, and wholly owns a precision casting division capable of producing single pieces under 35 tons, with an annual output of 12,000 tons. This ensures the quality and quantity for Tederic to produce high-quality injection molding machines with clamping forces ranging from 45 tons to 6,000 tons.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code