-

Reconstruction of Waterproof Industry Landscape: Beixin Fully Acquires Subsidiary, Three Giants Alliance Substantially Dissolves, Dongfang Yuhong Remains Industry Leader

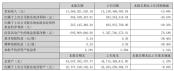

Image of waterproof membrane (Image source: Doubao AI) In December 2025, a landmark event occurred in the waterproofing industry—Beixin New Materials (Jinzhou) Co., Ltd. completed a significant adjustment in its equity structure. According to the in

Plastmatch -

Sanhe Coatings Launches Biodegradable Paint Containers Using PBAT Material

On August 7, 2025, Sanhe Paint announced that it would develop paint containers with biodegradable properties and apply them to the company's existing products. In January 2024, Sanhe Coatings signed a business agreement with SK Ribio, the investmen

puworld -

Oriental Yuhong Plans 880 Million RMB Acquisition of Leading Chilean Building Materials Retailer

On the evening of July 31, Oriental Yuhong announced that its wholly-owned subsidiaries, Oriental Yuhong Overseas Development Company and Oriental Yuhong International Trading Company, intend to invest approximately USD 123 million (about RMB 880 mil

Daihe Financial Cube -

[Major Breakthrough] Japan Sekisui Chemical Develops Non-PFAS Pipeline Material for Semiconductor Manufacturing

Sekisui Chemical Co., Ltd. recently announced that it has made key advancements in achieving PFAS (per- and polyfluoroalkyl substances)-free technology in ultrapure water piping materials for advanced semiconductor manufacturing. The com

PFAS-free -

Joint Initiative for Carbon Reduction in the Global Building Materials Industry Released

Global Initiative for Carbon Emissions Reduction in the Building Materials Industry To Colleagues Across the Global Building Materials Industry, As a critical pillar of the global economy, the building materials industry plays a vital

China National Building Materials Federation -

Dongfang yuhong acquires 880 million yuan stake in chilean building materials retail company

On July 17, Dongfang Yuhong announced in a statement that its wholly-owned subsidiary intends to acquire 100% of the shares of Chilean building materials retail company Construmart S.A. for $123 million (approximately 880 million yuan). According

JRJC -

Industry commentary: Quality Improvement of Stock Drives Structural Transformation of Building Materials Demand - Review of the Central Urban Work Conference

【Report Introduction】 The demand structure has shifted from incremental construction to stock updating. The upgrade in consumption has driven an increase in demand for high-quality green building materials. The acceleration of urbanization

China Galaxy Securities Research -

Sika and Sulzer to establish plastics recycling JV for the construction sector

Sika AG (Baar, Switzerland) and Sulzer Ltd. (Winterthur, Switzerland) have signed a memorandum of understanding to establish a joint venture (JV) to advance plastics recycling in the construction industry. The aim is to combine th

CHEMICAL ENGINEERING -

Borealis invests to increase capacity for recyclable, lightweight polymer foam solutions

Photo: Borealis invests over EUR 100 million in new High Melt Strength polypropylene (HMS PP) line at its Burghausen, Germany, facility.© Borealis -Borealis invests over EUR 100 million in new High Melt Strength polypropylene (HMS

Borealis -

Plastic Pipe Testing Lab Expands to Meet Growing Global Market

Global laboratory-based testing services leader Element Materials Technology has announced an expansion of its lab in Sweden specialized in plastic pipe testing. Element said the investment is designed to meet growing demand for specialize

PLASTICS TODAY -

"Science Advances" Study: Filler Defects Can Increase Polymer Thermal Conductivity by 160%

In the pursuit of designing new lightweight, flexible, and efficient heat dissipating materials for modern devices, the research team led by the University of Massachusetts Amherst has made a groundbreaking discovery: defects can also create advantag

Plastic Trends -

Pipe maker Ipex opens Ontario R&D facility

The $30-million facility in Mississauga features over 50,000 square feet of operational space. Ipex staff and Ontario Premier Doug Ford (ninth from right) at the opening of the new Ipex Centre for Advanced Research. Photo Credit: Ipex Group Oakville

Specialized Plastic Compilation -

Avient collaborates with Resia to utilize thermoplastic composite panels for efficient installation in modular construction.

Hammerhead™ composite panel, modular construction keywordsOn March 31, 2025, Avient is pleased to announce a successful collaboration with its key customer, Resia, a vertically integrated real estate company specializing in the development, construct

Lujie Consulting -

Notice on Convening the "25th National Plastic Weaving Industry Chain Technology Exchange and Market Matching Conference & China Plastics Processing Industry Association Plastic Weaving Special Committee Re-election Conference"

Notice on Convening the "2025 National Plastic Weaving Industry Chain Technology Exchange and Market Matching Conference the Re-election Conference of the Plastic Weaving Committee of China Plastics Processing Industry Association"Plastic woven indu

China Plastics Processing Industry Association -

U.S. Additional Tariffs on Polyurethane: How Rising Raw Material Costs and Corporate Innovation Transformation Are Reshaping the Market Landscape?

The recent tariff policy implemented by the United States is bringing significant uncertainty to the global polyurethane industry. Starting March 4, 2025, the U.S. will impose an additional ad valorem tariff of 20% on all polyurethane raw materials o

Daily Chemical Network -

What is the experience of living in a "recycled foam house"? German giants join forces to crack the code for reducing carbon in construction.

When a piece of discarded foam packaging was given a new lease of life on a construction site, it became an eco-guardian protecting the warmth of thousands of homes—a scene that might seem like science fiction but is a reality achieved by BASF, Sto,

Regenerative Resources Information Hub -

PPG has been named a "Great Place to Work" for the third consecutive year by Gallup.

PPG has been awarded the Gallup Exceptional Workplace Award (GEWA) for the third consecutive year. This annual award recognizes high-performing companies that put their employees at the center of their business strategies. Gallup has found that PPG c

NetEase Technology -

Green and performance double win for the cold plate industry ABG, BASF and Sto enter new market for the cold plate industry

German companies are making significant strides in the field of green building materials innovation. Recently, BASF, a leading German petrochemical company, Sto, a specialist in insulation systems, and ABG Frankfurt, a housing association, have joine

Specialized Translation -

Innovation in Building Plastic Materials, Empowering a Green Construction Future

In the wave of green transformation in the construction industry, plastic materials are reshaping the industry landscape with innovative technologies. Beijing Boao Hengrui Technology's recently approved patent for "Preparing High-Performance Soundpro

Guowei Plastics -

Has the turning point for polyurethane arrived? Is a significant price increase for MDI on the horizon?

Recently, Peter Huntsman, CEO of US-based polyurethane producer Huntsman, stated that the company has observed early signs of a potential recovery in the methylene diphenyl diisocyanate (MDI) market.Huntsman pointed out that MDI was one of the first

WELINK Plastics

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories