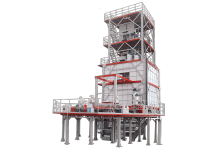

Jinming's SupereX series high-speed paper/aluminized film/aluminum foil extrusion laminating machine is a highly intelligent and high-performance equipment series introduced by Jinming. This equipment features high single-machine output, high degree of automation, and excellent control over film uniformity. Additionally, the SupereX series machines have good raw material adaptability, meeting customers' demands for high-quality and high-capacity film production.

Components Introduction

The multi-host high-speed extrusion laminating machine uses PE, PP, or EVA materials to laminate with reel paper substrates and aluminum foil or aluminized film, suitable for producing multilayer paper-plastic composite materials such as aseptic packaging paper, carton paper, cup paper, noodle bowl lids, and adhesive paper. The extruder features automatic temperature control, pneumatic feeding, stepless speed adjustment, and a hydraulic plunger screen changer, along with a high-precision bidirectional adjustable flat die head, ensuring high-quality continuous stable plasticizing extrusion performance.

The machine is equipped with an AC coating unit that uses a gravure engraved roller precision coating head with a leveling device. The doctor blade device can be manually adjusted in three dimensions (up/down, forward/backward, and angle) to ensure even coating.

The entire process from substrate unwinding to lamination and rewinding is controlled by a microcomputer with automated control. It is equipped with a color touchscreen and an integrated human-machine operation interface developed by our company, enabling most operations and controls of the machine. The software provides online help, shift production records, and online monitoring functions, making it very convenient for operators and engineering technicians to operate, control, and maintain the machine.

Technical Specifications

| Model | SJ120-GFMS1400T |

| Film Width | 800~1200mm |

| Film Thickness | 0.01~0.075mm |

| Substrate Thickness | Paper 120~350gsm; PET 0.012~0.05mm |

| Screw Diameter | Φ120mm |

| Die Head Width | 1450mm |

| Highest Line Speed | 250m/min |

| Unwinding Diameter | 1600mm |

| Rewinding Diameter | 1600mm |

| Total Installed Power | 1000kw |

| Dimensions | 35.6x11x4.5m |

Application Fields

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app