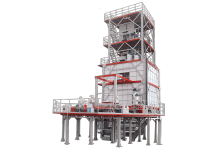

The Jinming ClassicX series blowing machine line is an optimized, customized, and high-capacity mid-to-high-end model introduced by Jinming based on existing machine models. Built on standard configurations, it can be customized according to the actual production processing needs and process conditions of customers, meeting high-quality production requirements for film uniformity control, transparency, stiffness, toughness, and output.

Component Introduction

Based on Jinming's extensive experience in extrusion system design and combining material processing characteristics with rheology principles, through continuous simulation and optimization, an extrusion system adaptable to various materials has been developed. The extruder is specifically optimized and precision-engineered for PVDF material processing, featuring high output, low energy consumption, and excellent plasticization.

Based on Jinming's extensive experience in die head design and combining material processing characteristics with rheology principles, through continuous technological innovation, Jinming has manufactured multiple high-performance die heads. Using a simulation system, the die head has been specially optimized for PVDF material processing, ensuring excellent film thickness tolerance.

The winder uses modular design with multiple winding functions, suitable for various materials. It supports interchangeable 3 or 6-inch winding shafts and features pre-acceleration for winding shafts, reducing tension fluctuations during roll changes. It offers automatic film cutting, automatic roll change, automatic unloading, automatic length counting, and fully automatic taper tension control. The fully automatic taper tension control system adjusts based on measured surface tension feedback, improving film winding flatness. This reduces labor intensity, minimizes waste during manual roll changes, enhances efficiency, and improves safety.

Technical Specifications

| Model | M2B-1700Q-C |

| Layers | 2 |

| Maximum Product Width | 1400mm |

| Conventional Product Thickness | 0.015-0.06mm |

| Suitable Raw Materials | HDPE, PVDF, etc. |

| Screw Diameter | Φ65mm×2 |

| Maximum Extrusion Rate | 180kg/H |

| Total Installed Power | 200kw |

| Highest Traction Speed | 80m/min |

| Dimensions (L×W×H) | 16.2×6.8×10.6m |

Application Areas

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app