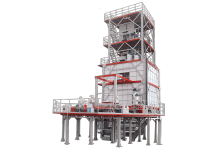

Jinming's SupereX series of film cast lines is a high-intelligence, high-performance equipment series introduced by Jinming. This equipment features high single-machine output, high degree of automation, and excellent film uniformity control. Additionally, the SupereX series machines have good raw material adaptability, meeting customers' demands for high-quality and high-capacity film production.

Component Introduction

Jinming's SupereX series of film cast lines is a high-intelligence, high-performance equipment series introduced by Jinming. This equipment features high single-machine output, high degree of automation, and excellent film uniformity control. Additionally, the SupereX series machines have good raw material adaptability, meeting customers' demands for high-quality and high-capacity film production.

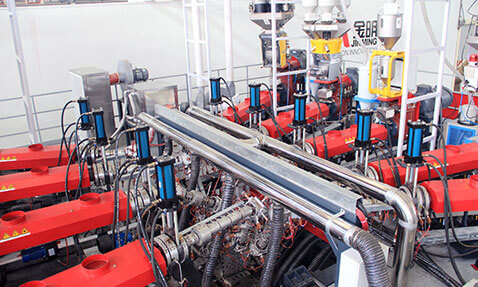

Extruder

Based on Jinming's 30+ years of experience in extrusion system design, various raw material processing performance parameters are tested through flow rate tests and screw rheological simulations. A low-temperature extrusion system adaptable to multiple different materials has been developed. It effectively reduces material extrusion temperature and shear, enhancing film physical properties and reducing unit energy consumption.

The die and automatic flat-die head system use a floating layered plug design that can adjust according to the extrusion volume. The three-dimensional melt channel reduces length and avoids dead zones. It features a single-material edge sealing system that effectively reduces the trimming loss of expensive materials. By optimizing processing parameters, it effectively solves the technical challenges of PA, EVOH, and other materials being encapsulated by other layers.

Equipped with a Siemens computer centralized control system, the central control unit PLC automatically controls the extrusion section, extrusion temperature control section, transmission control section, winding control section, edge trim collection control section, and roller temperature control section. The temperature control unit uses imported high-precision German temperature control modules. The touch screen provides a main menu interface where operators can easily set, modify, and query parameters for monitored objects.

Technical Parameters

| Model | M9L-2500 | M9L-3000 |

| Layers | 9 | 9 |

| Die Width | 2500mm | 3000mm |

| Film Width | 2100mm | 2600mm |

| Film Thickness | 0.03~0.25mm | 0.03~0.25mm |

| Suitable Raw Materials | PP, PE, EVA, POE, PA, EVOH, etc. | PP, PE, EVA, POE, PA, EVOH, etc. |

| Mechanical Speed | 150m/min | 150m/min |

| Maximum Extrusion Capacity | 830kg/H | 910kg/H |

| Total Installed Power | 850kVA | 950kVA |

| Dimensions (L x W x H) | 24x11x8m | 25x12x8m |

Application Fields

Whats App

Whats App

PlastMatch App

Scan the QR code

PlastMatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app